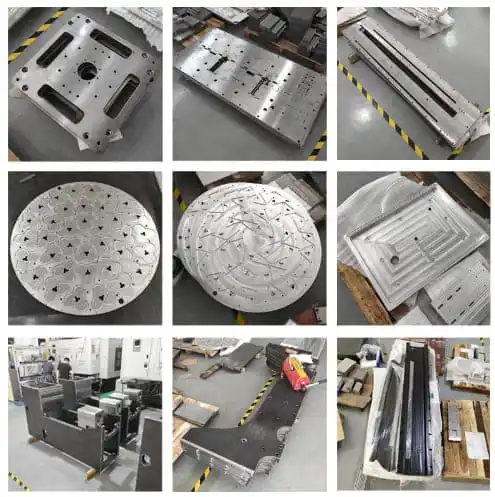

CNC Machining Parts Display

Precision Services: CNC Machining, Sheet Metal, Custom Fasteners

CNC Machining Services

Yijin Hardware Factory Provides Customers with One-Stop CNC Machining Services.

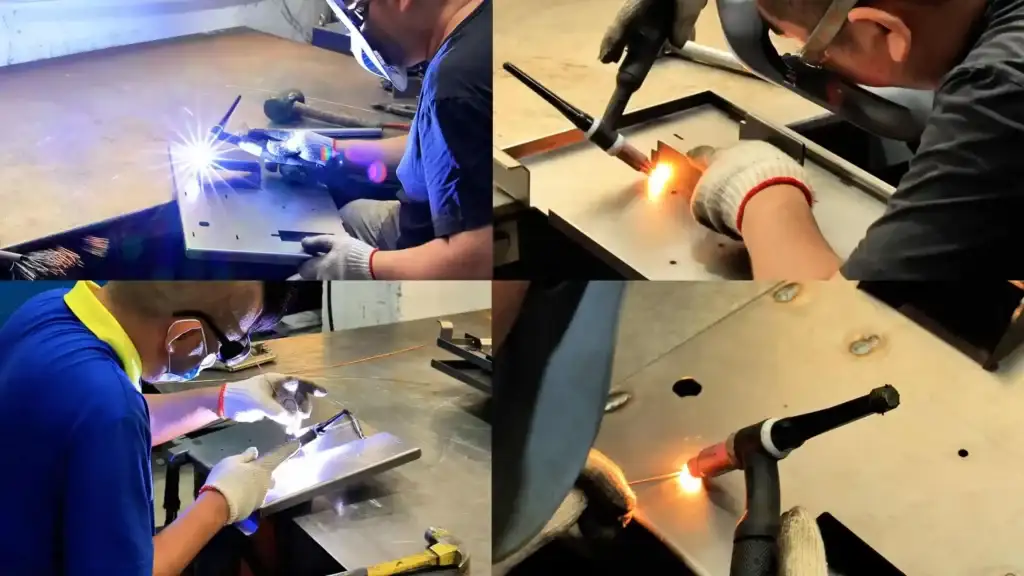

Sheet Metal Fabrication

From Design to Production, Offer Efficient Turnaround Times and Competitive Pricing for Your Sheet Metal Project.

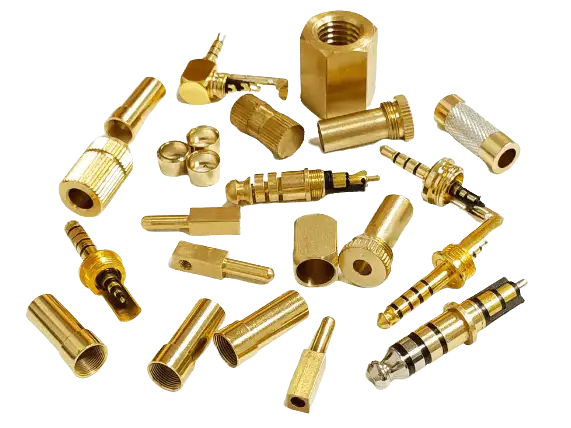

Custom Fasteners Services

Custom Fastener Products for Industries with High-Quality & Factory Prices.

Free Industrial Design Services

Let us collaborate to bring your ideas to life and propel your business to new heights.

Custom CNC Machining Parts Application Field

New Energy Industry

YIJIN Hardware as one of the top CNC machining parts manufacturers in China will provide you with a one-stop solution for your custom new energy parts.

Shipping Industry

Shipping is the largest transportation method that we can achieve in single transportation so far, which also highlights the importance of shipping.

Aerospace Industry

Aircraft parts production requirements are strict, and the parts produced need to have strong corrosion resistance. In addition to oxidation resistance, it should also ensure lightweight and high-strength impact resistance.

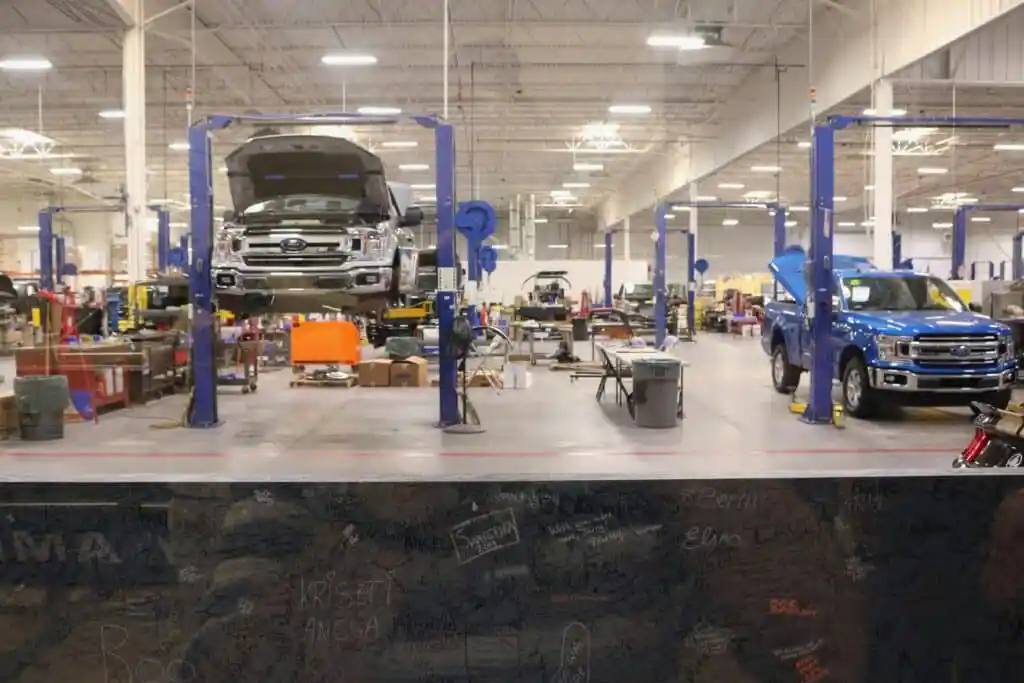

Auto Industry

Shipping is the largest transportation method that we can achieve in single transportation so far, which also highlights the importance of shipping.

Rapid Prototyping

First of all, 3D printing is a material increase technology, and CNC Rapid Prototyping is a material reduction technology, so they are very different in materials.

Consumer Products

As we all know, CNC machining centers are suitable for machining parts that are complex, have many procedures, are demanding, require multiple types of ordinary machine tools and many tool fixtures, and can only be processed after multiple clamping and adjustments.

Medical Industry

Medical care is very important to human life. As a

customized machining parts supplier, YIJIN Hardware has been committed to providing the best custom medical components for the medical industry.

Semiconductor Industry

Good quality, high-cost performance, favorable price, and a full set of pre-sales and after-sales services are the recognition of customers for the semiconductor parts we produce. Currently, we serve 7 semiconductor manufacturers.

Mold Making

CNC machining technology is mainly a technology adopted under digital information, with the characteristics of digitalization and automation.

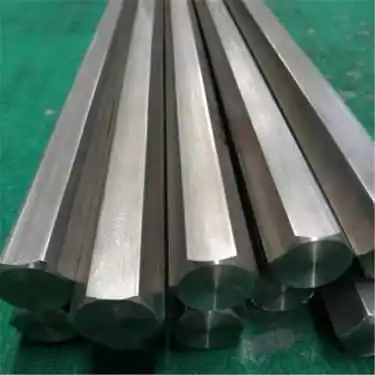

Machinable CNC Metal Materials

Brass, like copper, also has good machinability and excellent electrical conductivity. When it can make various electrical equipment and parts, it is also often used to make some beautiful handicrafts.

Alloy: Brass C360

Aluminum is the most common and commonly used metal in CNC machining services. Almost most CNC machining parts are made of Aluminum.

Alloy:

Aluminum 2017 | AlCu4MgSi

Aluminum 6063 | AlMg0,7Si

Aluminum 6060 | AlMgSi

Aluminum 6061-T6 | AlMg1SiCu

Titanium is a very good metal, it has excellent strength, and is very corrosion-resistant, light in weight, low thermal expansion, commonly used in biomedicine, of course, it also has applications in other areas, it is a very expensive metal

Alloy:

Titanium Grade 5 | 3.7164 | Ti6Al4V

Titanium Grade 2

Titanium Grade 1

Inconel has the characteristics of high strength and high corrosion resistance. It is often seen in aerospace and is an ideal material for aerospace applications..

Alloy:

Inconel 718

Invar is a nickel alloy with a very low coefficient of thermal expansion. Ideal for applications requiring high dimensional stability, such as precision instruments, engine valves, and large aerospace structural molds.

Alloy:

Invar

Mild steel is also called low carbon steel. The content of carbon metal in mild steel is very small. It can obtain good machinability, weldability and mechanical properties at a lower cost. The hardness of mild steel can also be gradually increased by carburizing.

Alloy:

Steel S235JR | 1.0038

Steel C45 | 1.0503

Steel S355J2 | 1.0570

Mild steel 1045

Mild steel A36

Mild steel 1018

Stainless steel alloys have high strength, ductility, wear resistance and corrosion resistance. They can be easily welded, machined and polished.

Alloy:

Stainless steel 416

Stainless steel 15-5

Stainless steel 301

Stainless steel 430

Stainless steel 440C | 1.4125

| X105CrMo17

Mild steel 1018

In addition to containing a certain content of carbon, alloy steel also adds other metal elements, so not only does it have a very strong India, but also because the content of other metals is increased, the hardness, toughness and fatigue are also improved accordingly. and wear resistance.

Alloy:

Alloy steel 1.7225 | 42CrMo4

Alloy steel 1.7131 | 16MnCr5

Alloy steel 1215

Alloy steel 4340

Alloy steel 4140

Copper is a metal with excellent thermal and electrical conductivity, and is often used to make wires, wire connectors, and other electrical applications in a wide range of applications.

Alloy:

Tool steel A3

Tool steel H13 | 1.2344

Tool steel S7

Tool steel O1

Tool steel A2 | 1.2363

Tool steel D2 | 1.2379

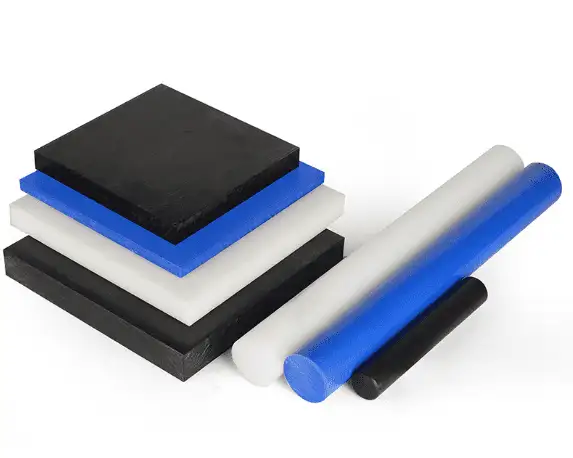

POM is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

Nylon – polyamide (PA) – is an engineering thermoplastic with excellent mechanical properties and high chemical and abrasion resistance.

ABS is a common thermoplastic with all-around good mechanical properties, excellent impact strength, good heat resistance and good machinability.

PTFE is an engineering thermoplastic with excellent chemical and thermal resistance and the lowest coefficient of friction of any know solid.

PVC is the third most used plastic with all-around good mechanical properties, excellent chemical and weather resistance and good toughness.

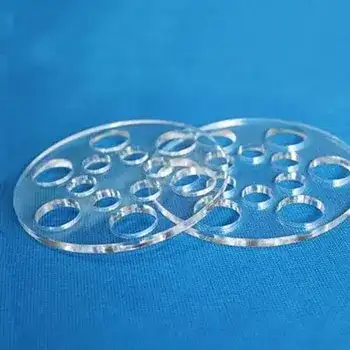

PMMA is a transparent rigid plastic often used as a substitute for glass.

Polypropylene is a thermoplastic synthetic resin with excellent properties, which is a colorless and translucent thermoplastic lightweight general-purpose plastic. It has chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and good high wear-resistant processing properties, etc.

G-10 is a high-pressure fiberglass laminate with a high strength, low moisture absorption, and high level of electrical insulation and chemical resistance. We can see it on most control knives

FR4 is a class of glass fiber epoxy laminate that is flame retardant, with similar properties to G-10.

CNC Custom Machining Parts Surface Treatment Types

Type II (MIL-A-8625, Type II) creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. Type III (MIL-A-8625, Type III, Class 1/2 “hardcoat”) is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

A hard coat anodize process that embeds PTFE to create a self-lubricating, dry contact surface with Type 3 hard coat’s protective properties. This finish can be used on aluminum alloys or titanium and increases the service life of the product. This finish conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed).

A surface finish for titanium per AMS-2488 Type 2 specification. Also called Tiodize, this finish increases fatigue strength and the wear resistance of a part. Titanium anodized parts are common in aerospace and medical device manufacturing. Non-pigmented titanium anodize finishes will dull shine.

Also known as buffing, a process of rubbing the surface of parts or utilizing a chemical action to produce a smooth and shiny surface, make the surface get significant specular reflection or reduce diffuse reflection in some materials.

Refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer, and can be done on metal or non-metal CNC machined components of any shapes, usually applied on aluminum, stainless steel and steel alloy parts. The purpose is to improve aesthetic appearance and prevent corrosion or oxidation.

A common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity.

A process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the machining metal surface or build up thickness for undersized parts.

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint. Can leave surface yellow/gold. Adds very little thickness, about 0.00001”-0.00004”. Chem film will conform to MIL-DTL-5541, TYPE I/II.

This is a process where powdered paint is sprayed onto a part that is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Black Oxide: Also known as blackening, gun bluing or hot blackening, a chemical process of forming a black conversion coating on stainless steel, copper and copper based alloys, zinc, powdered metals, silver solder, and ferrous materials, to improve corrosion resistance and minimize light reflection.

Conversion Coating: Also call as chromate conversion, the coating are used for metals converted to a protective layer through the chemical or electrochemical processes, primarily used as a corrosion inhibitor, decorative finish, or to retain electrical conductivity.

Bead blasting/Bead Blast: the process of removing surface deposits by applying fine glass beads at a high pressure without damaging the surface.

Abrasive Blasting/Sandblasting: the process or operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system, to remove surface contaminants, clean metals or increase a texture, then change the smoothness or roughness of surface.

YIJIN Hardware also provides grinding, linishing, industrial etching, and more custom metal finishing service for presenting the best effect of your part.

Why Choose Us?

Rapid Quotation

You will receive a quick quotation in 3-5 hours on work days after sending your design file with detailed specifications, sizes, and quantities. 24/7 support all year round.

High Quality

You rest assured to get high-quality CNC milling parts as desired with our careful drawing checks and strict quality inspections.

Wide Range of Materials

Choose from over 30 kinds of metal and plastic materials. YIJIN Hardware offers a wide variety of certified materials for your custom milling parts.

Custom Finishes

Select from a variety of finishes on the milled parts, such as anodizing, spray painting, vapor polishing, sandblasting, silk-screen, etc.

Quick Delivery

Your ordered parts can be finished as fast as one day and shipped to you right away. YIJIN Hardware features advanced technologies to accelerate production.

No MOQ

No minimum order quantity is required. One-piece prototypes, low-volume manufacturing or mass production at the most competitive price.

FAQs

CNC Macining refers to a series of processing methods for parts on CNC Macining machine tools. At the same time, CNC Macining is also a method of subtractive manufacturing.

It uses computerized equipment to remove excess material from the blank and uses numerical control machine tools to complete the required tasks. Because CNC machining is a general term for various precision machining such as CNC turning, CNC milling, CNC drilling, etc.

CNC machining can solve the variety of parts, small batches, complex shapes, etc. Through the various precision CNC machining methods just introduced and the problem of high precision.

Since the CNC machining is processed by the computer after the program is written. The precision CNC machining has stable processing quality, high precision, can process complex surfaces, and high processing efficiency.

It is an effective way to realize high-efficiency and automatic processing.

Our CNC machining services range is very wide.

Including: 5 axis cnc machining services, CNC milling services, CNC turning machining, CNC Drilling Services, small parts machining, gear machining servic, CNC cutting and Wire EDM services.

YIJIN Hardware’s CNC machining service integrates a number of advanced technologies to simplify the manufacturing process, speed up the mass production of CNC machined parts, and achieve higher precision and precision.

We are proud to produce CNC machined parts with the smallest tolerances and the highest precision. At the same time, we can also use EDM and grinding machines according to customer requirements manufacture precision parts.

The following is our related CNC machining services information.

As a metal manufacturing CNC machining company that YIJIN hardware produces CNC metal parts, customized machining parts according to customer’s requirements.

Parts machined from metal will follow ISO 2768-m (medium) or ISO 2768-f (fine). Parts machined from plastic will follow 2768 meters (middle).

Geometric tolerances as low as ± 0004 inches (0.010 mm) are possible but please marked in the technical drawing.

We can achieve tighter tolerances on shafts with manual quotes, up to H7 fits, sometimes tighter, so we are all strictly following ISO 2768 standard for all CNC machined parts

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

Blogs

10 Ways To Cut Stainless Steel Sheet

Cutting stainless steel is the process of cutting steel sheets into two or more parts. In steel cutting, the right

Sheet Metal Welding Process: Common Methods & Best Practices

Sheet metal welding joins two metal sheets to make lightweight and durable structures. It’s used across industries from aerospace to

Sheet Metal Forming Processes: A Complete Guide

Metal part manufacturing is critical for various industries, from construction to automotive. Metal manufacturing uses techniques like forming, joining, molding,

Start today. Get parts made fast.

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569