MENUMENU

- Services

- Industries

- AutomotivePrecision CNC machining solutions for automotive components, ensuring high performance, durability.

- AerospaceAdvanced CNC machining capabilities for aerospace parts, delivering lightweight, high-strength components.

- MaritimeCNC machining solutions for maritime applications, producing reliable components for vessels and shipping containers.

- Consumer ProductsPrecision machining services for consumer goods, enabling the production of high-quality products for various markets.

- MedicalSpecialized CNC machining services for medical device manufacturers, guaranteeing precise components.

- EnergySpecialized CNC machining for energy technologies, supporting the development of sustainable solutions.

- SemiconductorPrecision CNC machining for semiconductors, producing components for electronic devices.

- RoboticsPrecision-machined components powering advanced robotic systems, enhancing automation across industries with accuracy.

- Materials

- CNC MetalsStrong and versatile, metals are perfect for CNC machining. We excel in all metals, ensuring precision for your projects.

- CNC PlasticVersatile and lightweight, plastic materials offer excellent corrosion resistance and are suitable for various applications.

- AluminumVersatile and lightweight, plastic materials offer excellent corrosion resistance and are suitable for various applications.

- Stainless SteelWith its exceptional durability and resistance to corrosion, stainless steel is ideal for demanding applications.

- TitaniumKnown for its high strength-to-weight ratio and biocompatibility, titanium is ideal for aerospace, medical, and auto applications.

- MagnesiumLightweight yet durable, magnesium alloys are favored for their exceptional strength and machinability.

- BrassWith its exceptional machinability and enduring aesthetic appeal, brass stands out as a top choice for precision components.

- CopperRenowned for its versatility and conductivity, copper is indispensable in precision machining for various industries.

- Resources

- CNC GuidesDive into our comprehensive CNC machining guides designed to enhance your understanding of machining processes, tools, and best practices.

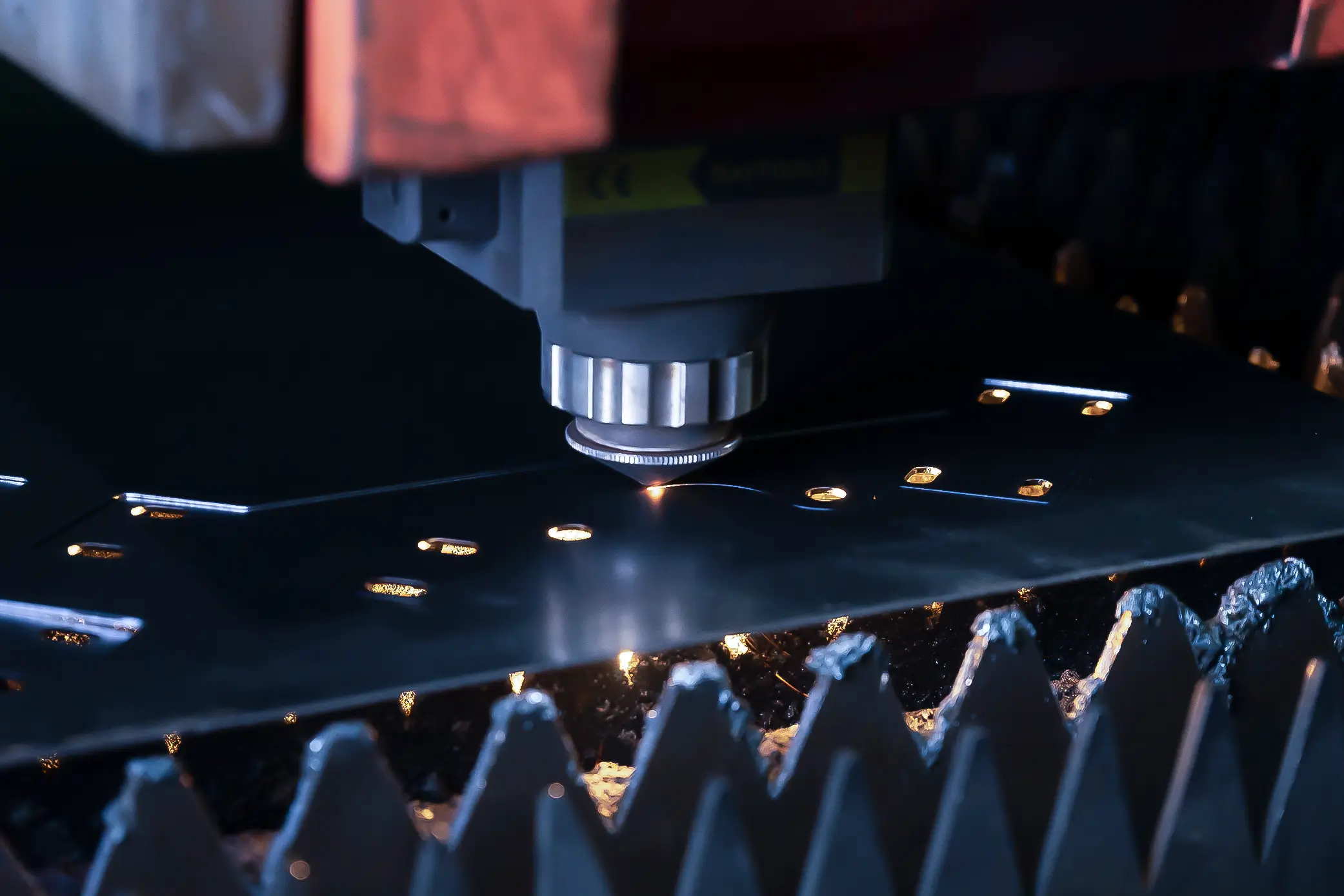

- Sheet Metal GuidesDiscover essential tips, techniques, and industry news on sheet metal fabrication. Learn about the best tools and practices for high-quality metalworking.

- News & BlogExplore our insightful blogs covering the latest trends, techniques, and innovations in machining. Stay updated with expert tips and industry news.

- Case StudiesDiscover real-world examples of our CNC machining projects, showcasing our precision, efficiency, and problem-solving capabilities.

- VideoImmerse yourself in our collection of informative videos, offering visual demonstrations, tutorials, and insights into the world of CNC machining.

- About

- CONTACT

Yabian Community, Shajing Street, Baoan District, Shenzhen, China

Explore our core values and company events reflecting our dedication to excellence and innovation in CNC machining.

Peek into our advanced CNC facility with virtual tours showcasing cutting-edge equipment and precision manufacturing.Find quick answers to common questions about our company and CNC services, streamlining your experience with us.

-

- Gallery

- Contact

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569