What is CNC Milling: Everythining You Need To Know

All of us know the term CNC milling. Everyone is talking about it and written some basic concepts which are

Yabian Community, Shajing Street, Baoan District, Shenzhen, China

Explore our core values and company events reflecting our dedication to excellence and innovation in CNC machining.

Get professional CNC turning services from YIJIN Hardware, the top-level CNC turned parts supplier in China. High-quality custom CNC turning parts with efficient production, fast delivery, and competitive pricing. With over 20 years of experience in CNC machining and CNC turned parts manufacturing, YIJIN Hardware provides you with the best CNC lathe services and custom CNC turning parts solutions.

Browse the list of CNC turning parts and components ordered from our customers worldwide.

As a leading CNC turning parts supplier, YIJIN Hardware has been providing highly reliable CNC turning services for various industries over the past 20 years.

With improved technologies and extensive expertise in CNC machining, YIJIN Hardware produces high-quality and cost-effective metal/plastic custom CNC turned components with high precision guaranteed for your innovative projects.

As a leading CNC turned parts manufacturer, YIJIN is equipped with the most advanced CNC turning machines and professional expertise to help you with your unique projects.

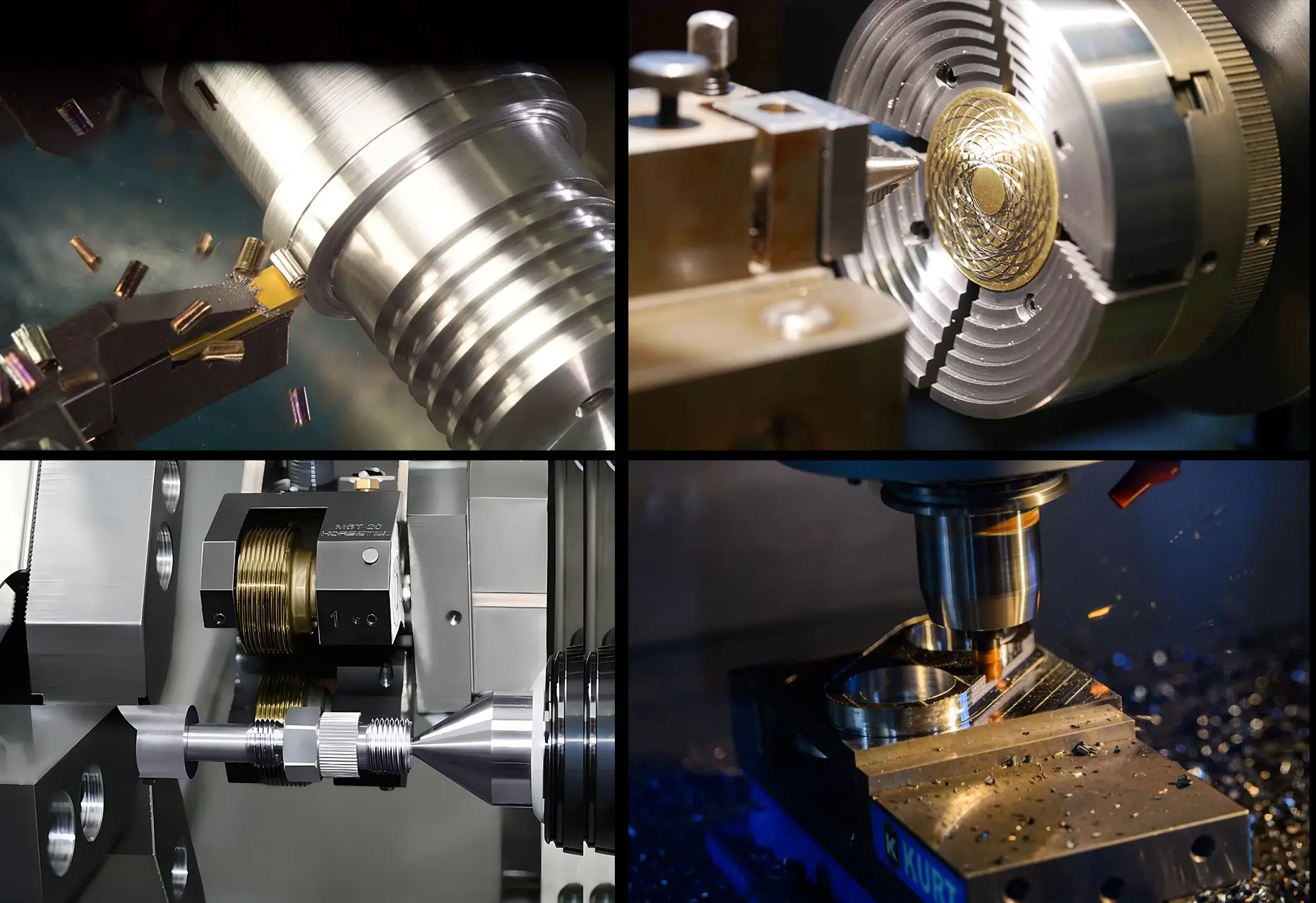

CNC turning service is a specific type of CNC machining process that involves material removal.

During the CNC turning process, the workpieces are held in a chuck and rotated while the turning cutter is fed to the workpiece to cut materials away until the desired custom CNC turned parts are created.

Working on the same principle as a lathe, CNC turning adopts one of the most traditional forms of manufacturing.

Assisted by computer numeric control (CNC), it promises high accuracy.

With CNC lath services, feed is measured in inches per revolution (ipr) or millimeters per revolution (mpr).

CNC turning is perfect for dealing with cylindrical-shaped workpieces such as shafts, disks, and shaft sleeves (although it can also be used for square or hexagonal-shaped parts).

Compared with traditional manual machining, the CNC machine, the core part of CNC lathe services, gains popularity with the following unique features and unbeatable benefits:

CNC turning can be carried out in a variety of materials including different metals and plastics. Below is a list of the most commonly used materials for CNC turning parts and components. More material types and grades are available upon request. Contact us for inquiries and quick CNC turning parts quotes.

CNC turning provides you with a fast and reliable solution to create your custom parts with tons of advantages, including the following:

CNC turning is numerically controlled by programs, therefore the precision CNC turned parts can achieve extremely high accuracy and precisionaccording to the design files without any human errors during the process.

CNC turning also produces high surface quality that sometimes requires no post-processing.

CNC turning is a low-cost solution to produce parts and components in low or large volumes.

The savings mostly come from its fast production capability, which reduces the overall CNC turned part cost, and also the labor and management cost.

Remember to contact a reliable and experienced CNC turned part manufacturer so you can benefit from its advanced facilities at the most competitive price.

CNC turning production can be scaled up very quickly as you demand.

This type of precision machining can produce thousands of precision CNC turned parts fast with constant quality standards from the beginning to the end.

That’s to say, you will find the last CNC turned part exactly the same as the first one in the production line.

Supported by a highly professional and efficient CNC turned parts factory, YIJIN Hardware is able to handle on-demand CNC turning parts with high precision and fast delivery.

Find quick answers to questions about CNC turning and Yijin as a top CNC turning part supplier.

While capable of processing square and hexagonal-shaped materials, the CNC turning process is best for tubular and circular shaped raw materials, including the following:

Modern CNC turning machines are capable of handling different tools, spindles, and speeds. With various cutting tools available, CNC turning machines can create different parts with complex geometries. Generally, CNC turning is popular for making parts with the following criteria:

Overall, CNC turned parts are widely used in the field of machine manufacturing, aerospace, automobile part manufacturing, and service factories.

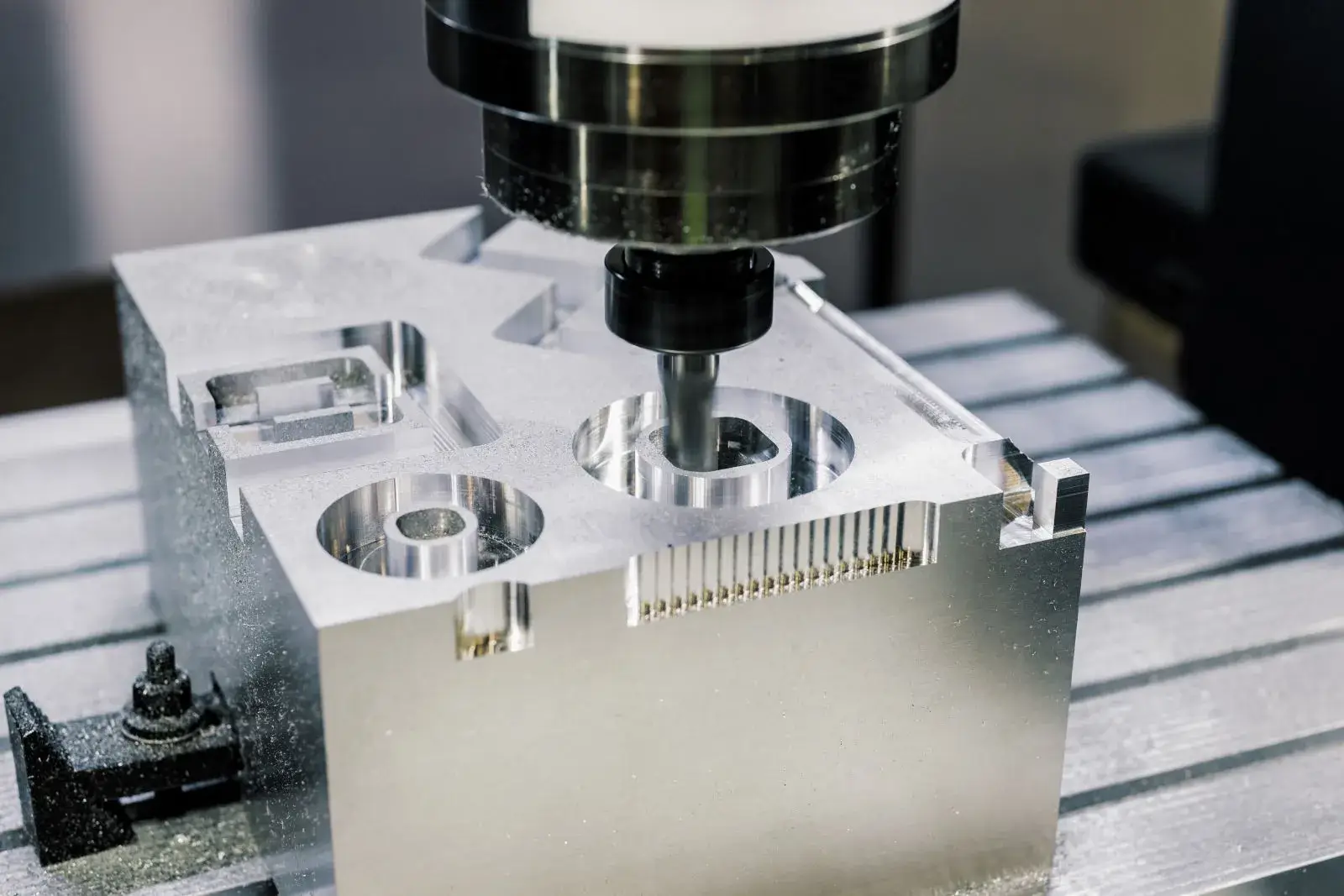

CNC turning service rotates the workpiece instead of the tool and it’s mainly used for irregular and flat surfaces.

By contrast, CNC milling rotates the cutting tools against the workpieces, and this process is ideal for creating cylindrical or conical parts.

Generally, CNC turning and milling are combined to make custom precision machining parts.

YIJIN Hardware provides both CNC milling and turning services and will advise the best CNC milling or turning solution to manufacture your parts according to the design files and requirements.

The cost of your CNC turning parts varies depending on a lot of factors, including the complexity of your design (operations needed during the process), the materials (think about aluminum vs copper), the feature requirement, etc.

Recommended: 2023 Top 10 CNC Design Services Companies In China

The best (and easiest) way to know the cost of your CNC turning part accurately is to send us a message with your drawings (in the format of stp, *.sldprt or igs for 3D/dwg, dxf, png, pdf or jpg for 2D) and quantity requirement. We will get back to you with detailed quotations and suggestions.

As a world-leading custom CNC turned parts supplier, Yijin always provides better CNC turning services and products at less cost

CNC in full form is computer numerical control and therefore the CNC turning machine is operated by computer programs.

Compared with the traditional lathe, the CNC lathe service can produce complex custom parts and components to precise specifications according to your design files.

CNC turning is usually performed either on the CNC lathe or turning center. What is CNC turning center?

Generally speaking, the CNC turning centers are more advanced than the CNC lathe with the capabilities of facing, threading, knurling, drilling, boring, reaming, milling and turning.

You will receive a quick quotation in 3-5 hours on work days after sending your design file with detailed specifications, sizes, and quantities. 24/7 support all year round.

You rest assured to get high-quality CNC milling parts as desired with our careful drawing checks and strict quality inspections.

Choose from over 30 kinds of metal and plastic materials. YIJIN Hardware offers a wide variety of certified materials for your custom milling parts.

You will receive a quick quotation in 3-5 hours on work days after sending your design file with detailed specifications, sizes, and quantities. 24/7 support all year round.

Your ordered parts can be finished as fast as one day and shipped to you right away. YIJIN Hardware features advanced technologies to accelerate production.

No minimum order quantity is required. One-piece prototypes, low-volume manufacturing or mass production at the most competitive price.

All of us know the term CNC milling. Everyone is talking about it and written some basic concepts which are

In the manufacturing industry, computer numerical code, or CNC systems, is one meaningful breakthrough in technology. The process now involves

Planes, rockets, vehicles, and boats are all items made using a manufacturing technology called CNC machining. You may be pretty

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

Quick links

Contact

© 2024 Yijin Hardware. All rights reserved

WhatsApp us