Aluminum CNC (Computer Numerical Control) parts have gained significant popularity across various industries due to their exceptional properties and versatile applications.

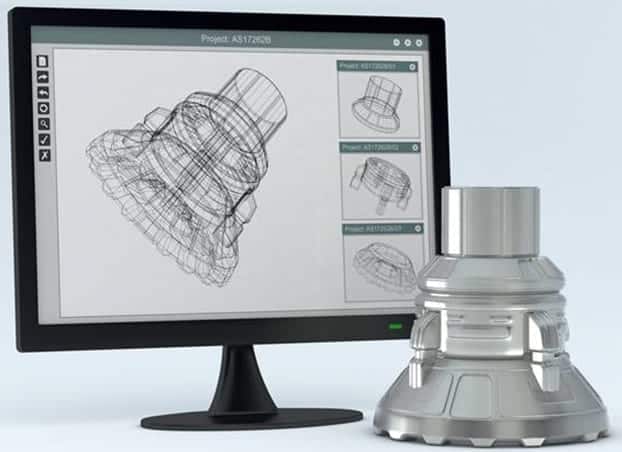

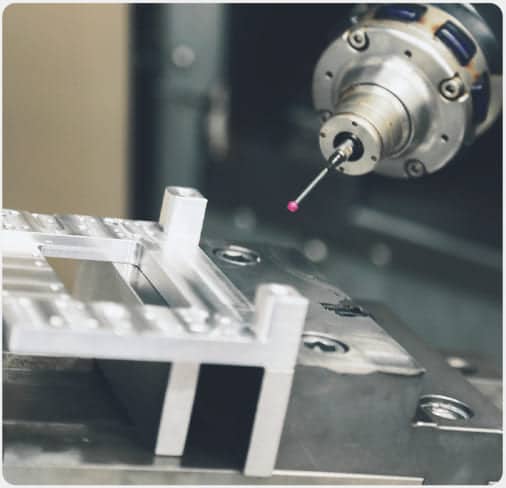

CNC machining involves using computer-controlled machines to precisely cut and shape aluminium blocks into intricate and accurate components.

This process offers high precision, consistency, and the ability to create complex designs, making aluminium CNC parts a preferred choice in numerous sectors.

Importance of Aluminium in CNC Machining

Aluminium holds significant importance in CNC machining due to its unique combination of properties that make it an ideal material for producing precision components through computer numerical control (CNC) processes.

Here are some key reasons why aluminium is widely used and valued in CNC machining:

- Lightweight and High Strength-to-Weight Ratio: Aluminium is very light in nature so, it is an ideal material low weight plays an important role.

- Machinability: Aluminum is considered one of the most machinable metals, and it responds well to CNC machining processes. Aluminium can easily undergoes drilling, turning, and knurling to gain the desired shape.

- Thermal Conductivity: Aluminum has good thermal conductivity it means can transfer heat effectively. This property is highly beneficial for applications involving heat sinks, electronic enclosures, and components that require effective heat management.

- Corrosion Resistance: This feature makes aluminium CNC parts suitable for applications in various environments, including those exposed to moisture or chemicals.

- Aesthetic Appeal: Aluminum has a clean and attractive appearance, making it a preferred choice for components that require a polished, anodized, or decorative finish.

- Electrical Conductivity: Aluminum offers good electrical conductivity, making it suitable for components that require efficient electrical connections or grounding, such as connectors, terminals, and electrical enclosures.

- Recyclability: Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to primary production. This environmental sustainability aspect is increasingly important in modern manufacturing practices.

- Cost-Effectiveness: Aluminum is generally more cost-effective compared to other metals, such as titanium or stainless steel. Its availability, combined with its favourable machining characteristics, makes it a cost-efficient choice for many applications.

- Wide Range of Alloys: Aluminum alloys come in a variety of compositions, each offering specific mechanical and chemical properties. This allows engineers and manufacturers to select the right alloy to match the requirements of the intended application, whether it’s for strength, corrosion resistance, or other factors.

- Versatility: Aluminum’s versatility extends to various machining processes, including milling, turning, drilling, tapping, and more. This versatility enables the creation of intricate and complex shapes, making it suitable for a wide range of components and parts.

In CNC machining, the combination of aluminium’s properties with the precision and automation capabilities of CNC processes allows for the production of high-quality, intricate, and customized parts across numerous industries.

As a result, aluminium remains a cornerstone material in modern manufacturing and plays a vital role in advancing technology and innovation.

Introduction to Aluminium CNC Parts Applications

1. Aerospace Industry: A Major Arena for Aluminium CNC Parts

The aerospace industry is indeed a major arena for the use of aluminium CNC parts, playing a critical role in the development of modern aircraft, satellites, and spacecraft.

Aluminium CNC parts offer several advantages that align well with the aerospace industry’s requirements, including lightweight design, strength-to-weight ratio, and ease of machining.

Here are the key applications of aluminium CNC parts in the aerospace sector:

a. Aircraft Components:

- Fuselage and Wings: Aluminium CNC parts are extensively used in the construction of aircraft fuselage and wings. The lightweight yet sturdy properties of aluminium contribute to the overall weight reduction of the aircraft, enabling better fuel efficiency and increased payload capacity.

- Engine Nacelles: CNC-machined aluminium parts are employed in the engine nacelles, which encase and protect the aircraft’s engines. Aluminium’s thermal conductivity helps dissipate heat efficiently, contributing to engine performance and safety.

- Landing Gear Components: Aluminium CNC parts are utilized in the production of landing gear components, such as struts and structural elements. The lightweight design enhances the aircraft’s ability to take off and land safely.

b. Satellites and Spacecraft:

- Satellite Structures: Aluminium CNC parts play a significant role in constructing satellite frames and structures. The lightweight properties of aluminium are critical in ensuring that satellites can be launched efficiently and achieve the desired orbits.

- Spacecraft Components: CNC-machined aluminium parts are used in various spacecraft components, such as body panels, antennae, and payload bays.

- Payload Carriers: Aluminium CNC parts are employed in payload carriers, which are used to transport scientific instruments and equipment to space. The lightweight design contributes to more cost-effective and efficient launches.

c. Weight Reduction and Fuel Efficiency:

- Fuel Tanks: Aluminium CNC parts are used in manufacturing fuel tanks for both aircraft and spacecraft. Aluminium’s corrosion resistance and strength-to-weight ratio make it an ideal material for fuel storage while reducing the overall weight of the vehicle.

- Secondary Structures: Aluminium CNC parts are utilized in secondary structures of aircraft and spacecraft, such as fairings, ribs, and brackets. These components contribute to weight reduction and structural integrity.

- Fasteners and Fittings: Aluminium CNC parts are employed in producing fasteners and fittings used in assembling various aerospace components. Aluminium’s lightweight nature minimizes the overall weight of the vehicle while ensuring structural integrity.

In summary, the aerospace industry relies heavily on aluminium CNC parts due to their lightweight, strength, and ease of machining.

From aircraft components to satellites and spacecraft, aluminium CNC parts continue to shape the industry by improving fuel efficiency, increasing payload capacity, and contributing to the advancement of space exploration.

2. Automotive Industry and Aluminium CNC Parts Applications

The automotive industry has embraced the use of aluminium CNC parts in various applications due to the numerous advantages they offer, such as lightweight, improved performance, and cost-effectiveness.

Aluminium CNC parts play a crucial role in enhancing the efficiency, safety, and overall driving experience of vehicles.

Here are the key applications of aluminium CNC parts in the automotive sector:

a. Engine Components:

- Cylinder Heads: Aluminium CNC parts are commonly used in manufacturing cylinder heads, which form a critical part of the engine. Due to the low weight of aluminium, The actual engine weight is reduced, resulting in better fuel efficiency and performance.

- Engine Blocks: CNC machining enables the precise manufacturing of aluminium engine blocks. Aluminium blocks offer excellent heat dissipation and weight reduction, contributing to improved engine performance and reduced emissions.

- Intake Manifolds: Aluminium CNC parts are employed in producing intake manifolds, which play a vital role in delivering air and fuel to the engine cylinders. Aluminium’s thermal conductivity ensures efficient heat transfer, enhancing combustion efficiency.

b. Chassis and Suspension System:

- Control Arms: Aluminium CNC parts are used to create lightweight and durable control arms in the suspension system. The reduced weight of aluminium control arms improves vehicle handling and ride comfort.

- Steering Components: CNC-machined aluminium parts are utilized in steering components, such as steering knuckles and tie rods. These parts contribute to precise steering response and better control over the vehicle.

- Subframes: Aluminium CNC parts are employed in the construction of subframes that support various vehicle components.

c. Lightweighting and Increased Performance:

- Body Panels: Aluminium CNC parts are used for manufacturing body panels, such as doors, hoods, and fenders. Substituting steel with aluminium panels reduces the vehicle’s weight, leading to improved fuel efficiency and acceleration.

- Wheels: Aluminium CNC parts are utilized to manufacture lightweight and durable wheels, contributing to reduced unsprung weight and enhanced handling characteristics.

- Transmission Components: CNC-machined aluminium parts are employed in the transmission system, resulting in weight reduction and improved transmission efficiency.

- Brake Components: Aluminium CNC parts find application in brake callipers and other brake system components. The lightweight design aids in reducing braking distances and improving overall braking performance.

Overall, the use of aluminium CNC parts in the automotive industry has become instrumental in achieving lightweight objectives and enhancing vehicle performance.

The advantages of aluminium, including its low density, high strength-to-weight ratio, and machinability, make it an attractive choice for automotive manufacturers seeking to produce more fuel-efficient, environmentally friendly, and high-performing vehicles.

Recommended: 2023 Top 10 Auto Spare Parts Manufacturing In China

3. Medical Industry’s Use of CNC Aluminium Parts

The medical industry extensively utilizes CNC aluminium parts for various applications due to their biocompatibility, lightweight, and precision manufacturing capabilities.

CNC aluminium parts play a vital role in the growth of medical technology.

Here are some specific uses of CNC aluminium parts in the medical field:

a. Surgical Instruments:

- Scalpels and Surgical Blades: CNC aluminium parts are used to create surgical instruments like scalpels and surgical blades. Precision machining ensures sharp edges and consistent dimensions, enabling precise and safe incisions during surgeries.

- Forceps and Graspers: Aluminium CNC parts are employed to manufacture forceps, graspers, and other handheld surgical instruments. The lightweight and durable nature of aluminium makes these instruments easy to handle and sterilize.

- Trocars and Cannulas: CNC aluminium parts are utilized to produce trocars and cannulas used in minimally invasive procedures. These instruments enable access to the surgical site through small incisions, reducing patient trauma and recovery time.

b. Medical Devices and Equipment:

- Imaging Equipment Components: Aluminium CNC parts are widely used in medical imaging equipment, such as MRI machines, CT scanners, and X-ray machines. The parts ensure precise alignment and stability of the equipment, contributing to accurate imaging results.

- Respiratory Devices: CNC aluminium parts are employed in the manufacturing of respiratory devices, including ventilator components and oxygen concentrators. The lightweight nature of aluminium makes these devices more portable and user-friendly.

- Infusion Pumps and Fluid Delivery Systems: Aluminium CNC parts are utilized in the construction of infusion pumps and fluid delivery systems.

c. Prosthetics and Biocompatibility:

- Prosthetic Limbs and Components: CNC aluminium parts are used in the production of lightweight and durable components for prosthetic limbs. The customizability and precision of CNC machining enable the fabrication of prosthetics tailored to individual patient needs.

- Orthopaedic Implants: Aluminium CNC parts are used in orthopaedic implants such as bone plates, screws, and rods. The biocompatibility of aluminium makes it a suitable material for implantable devices, ensuring compatibility with the human body.

- Medical Braces and Supports: CNC aluminium parts are utilized in the manufacturing of medical braces and supports used for rehabilitation and recovery purposes.

The use of CNC aluminium parts in the medical industry highlights their critical role in enhancing medical procedures, patient care, and quality of life.

The biocompatibility, precision, and versatility of aluminium CNC parts make them a valuable choice for medical professionals and device manufacturers seeking reliable and efficient solutions in healthcare applications.

4. Electronics and Communication: Applications for Aluminium CNC Parts

Aluminium CNC parts find various applications in the electronics and communication industry, owing to their lightweight, thermal conductivity, and excellent machining capabilities.

Here are some specific applications of aluminium CNC parts in this field:

a. Enclosures and Heat Sinks:

- Electronic Device Enclosures: Aluminium CNC parts are commonly used to manufacture enclosures for electronic devices such as smartphones, laptops, tablets, and routers. These enclosures protect the internal components from external factors, provide structural support, and offer an aesthetically appealing design.

- Amplifier and Power Supply Housings: High-power electronic devices like amplifiers and power supplies generate heat during operation. Aluminium CNC parts can fabricate heat sinks and housing structures to dissipate the heat efficiently, preventing overheating and ensuring proper device functioning.

- LED Light Fixtures: In LED lighting applications, aluminium CNC parts are utilized to create heat sinks that manage the heat generated by LEDs, thus prolonging the lifespan of the lighting system.

b. Electrical Connectors, Switches, and Components:

- Electrical Connectors: Aluminium CNC parts are suitable for producing electrical connectors in various electronic systems. These connectors ensure reliable electrical connections and can be found in devices ranging from consumer electronics to industrial equipment.

- Switch Components: Aluminium CNC parts manufacture switch components such as buttons and sliders in keyboards, remote controls, and other user interfaces.

- Printed Circuit Board (PCB) Supports: Aluminium CNC parts can be used as spacers and supports for PCBs, providing stability and proper positioning of electronic components.

c. Antenna Structures:

- Antenna Radomes: Aluminium CNC parts are employed to fabricate radomes that encase and protect antennas from environmental factors. Radomes ensure that the antenna operates efficiently by reducing the impact of wind, rain, and other external elements.

- Satellite and Communication Antennas: Aluminium CNC parts are used to construct satellite dishes and communication antennas. These components may be bent to improve antenna performance and are lightweight, strong, and versatile.

- Mobile Device Antenna Frames: Aluminium CNC parts are utilized in mobile devices to create frames that support and shield antennas, ensuring optimal signal reception and transmission.

Overall, using aluminium CNC parts in electronics and communication applications offers several benefits, including lightweight construction, thermal management, electrical conductivity, and precise manufacturing capabilities.

These features make aluminium CNC parts a popular choice for a wide electronics and communication industry product range.

5. Aluminium CNC Parts in Robotics and Automation

Aluminium CNC parts have become increasingly prevalent in robotics and automation, revolutionizing the design and capabilities of robotic systems.

The use of aluminium CNC parts in robotics and automation can be explored in the following areas:

a. Lightweight Structural Components:

- Robot Frames and Chassis: Aluminium’s lightweight properties make it an ideal material for constructing robot frames and chassis. Aluminium CNC parts enable the creation of solid and rigid structures without adding unnecessary weight, leading to improved energy efficiency and enhanced manoeuvrability for robotic platforms.

- Mobile Robots and Drones: Weight directly impacts the performance and endurance of mobile robots and drones. Aluminium CNC parts facilitate the production of lightweight and durable components, allowing robots and drones to navigate challenging terrains, fly for extended periods, and carry out tasks with greater agility.

- Exoskeletons: Exoskeletons are wearable robotic systems that support and improve human movement in industrial and medical settings. Aluminium CNC parts enable the development of lightweight and ergonomic exoskeletons, reducing the burden on users and increasing the overall comfort and usability of the device.

b. Customized Robotic Arms and Tools:

- Robot Arms: Aluminium CNC parts enable the customization and precise fabrication of robotic arms tailored to specific applications. These custom-designed arms can be optimized for strength, reach, and payload capacity, making them suitable for a wide range of tasks, from assembly and pick-and-place to welding and material handling.

- End Effectors and Grippers: The end effectors and grippers are critical components of robotic arms responsible for interacting with objects. Aluminium CNC parts allow for the production of lightweight, yet robust and adaptable end effectors and grippers, ensuring precise and safe manipulation of various objects.

- Collaborative Robots (Cobots): Aluminium CNC parts are instrumental in developing collaborative robots that can safely work alongside humans. The use of lightweight components enables cobots to have a lower impact force during accidental collisions, ensuring a safer working environment.

c. High-Precision Movement and Adaptability:

- Joints and Linkages: Aluminium CNC parts facilitate the construction of high-precision joints and linkages for robotic systems. These components ensure smooth and accurate movements, essential for tasks requiring precise positioning and repetitive actions.

- Sensor Mounts and Camera Housings: Robotics heavily rely on sensors and cameras for perception and navigation. Aluminium CNC parts can be utilized to create sturdy and lightweight mounts and housings for these sensors, enabling better accuracy and stability during data collection.

- Modular Design: Aluminium CNC parts are used in the creation of modular robotic systems. The use of modular components allows for easy reconfiguration and adaptability, allowing robots to be quickly equipped with specialized tools or reprogrammed for various tasks.

Overall, the integration of aluminium CNC parts in robotics and automation contributes to more efficient, flexible, and capable robotic systems.

The lightweight nature, customizability, and high-precision characteristics of aluminium CNC parts empower robotics engineers to design advanced machines that can perform a diverse range of tasks, enhance productivity, and adapt to changing operational requirements.

Future Prospects and Emerging Applications of Aluminium CNC Parts

The future prospects of aluminium CNC (Computer Numerical Control) parts are promising, driven by ongoing advancements in CNC machining technology and the growing demand for lightweight, durable, and sustainable materials across various industries.

As CNC capabilities improve and new applications are explored, aluminium CNC parts are likely to find their way into emerging sectors.

Here are some potential future prospects and emerging applications:

1. Renewable Energy: Solar Panels and Wind Turbines

Future prospects for aluminium CNC parts in the renewable energy sector, particularly in solar panels and wind turbines, are promising due to the increasing demand for clean and sustainable energy sources.

Here are some emerging applications:

- Solar Panel Frames: Aluminium CNC parts can be used to fabricate lightweight and durable frames for solar panels. These frames provide structural support and protection for delicate solar cells, enabling easier installation and improved energy efficiency.

- Heat Sinks for Solar Inverters: The direct current (DC) from solar panels is converted into alternating current (AC) for usage in homes and businesses by solar inverters, which are essential parts of solar power systems. Aluminium CNC parts can be used to create efficient heat sinks, dissipating heat and enhancing the performance and reliability of solar inverters.

- Wind Turbine Components: In the wind energy sector, aluminium CNC parts can find application in manufacturing various components of wind turbines, such as hubs, nacelles, and rotor blades. Lightweight aluminium parts help reduce the overall weight of the turbine and improve its efficiency in harnessing wind energy.

- Mounting Systems: Aluminium CNC parts can be used to create mounting systems for solar panels and wind turbines. These systems allow for secure installation, proper alignment, and adjustment of renewable energy equipment to maximize energy capture.

2. 3D Printing Technology and Innovations

The combination of aluminium CNC parts with 3D printing technology opens up exciting possibilities for various industries.

As 3D printing advances, aluminium CNC parts can be incorporated into this additive manufacturing process, leading to the following potential applications:

- Hybrid Components: Hybrid manufacturing, which combines CNC machining and 3D printing, can produce complex geometries that are challenging to achieve using traditional machining alone. Aluminium CNC parts can be integrated with 3D printed components, offering enhanced strength, precision, and design flexibility.

- Prototyping and Rapid Tooling: Rapid prototyping of innovative product ideas is made possible by 3D printing. Aluminium CNC parts can be used to quickly create customized tooling and fixtures, facilitating the development process and reducing time-to-market for new products.

- Aerospace Components: The aerospace industry can benefit from 3D-printed aluminium parts for non-critical components, while critical components can be machined using aluminium CNC parts. This combination allows for weight savings without compromising safety and structural integrity.

- Medical Devices: Aluminium CNC parts can be used with 3D printing to manufacture medical devices, such as prosthetics, orthopaedic implants, and surgical instruments, offering precise and tailored solutions for patients.

3. High-Speed Rail and Transportation Industries

Aluminium CNC parts have long been used in the transportation sector due to their lightweight and robust characteristics.

The high-speed rail and transportation industries hold promising prospects for aluminium CNC parts in the following ways:

- Lightweight Structures: High-speed rail systems benefit from the reduced weight of aluminium CNC parts in train components, such as body frames, doors, and interior fittings. The weight reduction contributes to improved energy efficiency and faster acceleration.

- Aircraft Interiors: In the aviation industry, aluminium CNC parts can create lightweight and durable interior components for aircraft, such as seats, overhead bins, and galleys, enhancing passenger comfort and fuel efficiency.

- Electric Vehicle Components: In the transportation industry’s shift towards electric vehicles, aluminium CNC parts play a crucial role in manufacturing lightweight components like chassis, battery housings, and drivetrain parts, contributing to longer driving ranges and increased efficiency.

As technology and materials continue to evolve, aluminium CNC parts are likely to play an increasingly significant role in these sectors, driving innovation, sustainability, and efficiency across industries.

The Evolving Role of Aluminium CNC Parts Applications Across Industries

The use of Aluminium CNC (Computer Numerical Control) parts has been steadily evolving across industries due to their numerous advantages and versatility.

CNC machining involves computer-controlled machines that can precisely cut and shape aluminium parts based on digital designs, allowing for high accuracy and repeatability.

Advantages of Aluminium in Various Applications

- Lightweight: Aluminium is very light in nature so, it is an ideal material low weight plays an important role. The aircraft and automotive industry is an ideal application for aluminium material.

- Strength-to-Weight Ratio: Although lightweight, aluminium exhibits a remarkable strength-to-weight ratio, providing structural integrity and stability to products while keeping their overall weight low. This feature makes it suitable for engineering applications, automotive components, and sporting equipment.

- Corrosion Resistance: Aluminium forms a protective oxide layer when exposed to the atmosphere, giving it excellent corrosion resistance. This property makes it highly desirable for outdoor and marine applications, where exposure to moisture and other environmental factors can be a concern.

- Thermal Conductivity: Aluminium possesses excellent thermal conductivity, making it useful in heat exchange systems, such as radiators, air conditioning units, and heat sinks in electronic devices.

- Electrical Conductivity: The metal’s electrical conductivity makes it a popular choice for electrical components and conductors in various industries, including electronics and power transmission.

- Machinability: Aluminium is relatively easy to machine compared to many other metals, making it a preferred material for CNC (Computer Numerical Control) parts manufacturing.

The Potential for Growth and Further Development:

- Automotive Industry: The automotive industry is constantly looking for ways to cut emissions and increase fuel efficiency. As such, there is a growing trend towards using aluminium CNC parts to replace heavier components in vehicles, leading to improved performance and sustainability.

- Aerospace Industry: The aerospace industry has long valued aluminium for its lightweight and corrosion-resistant properties. As technology advances, further developments in aluminium alloys and CNC machining techniques may lead to even lighter and stronger components, enabling more fuel-efficient aircraft and space vehicles.

- Renewable Energy: The renewable energy sector, particularly in solar and wind energy, could see increased usage of aluminium CNC parts for structural components and enclosures.

- Electronics and Consumer Goods: With the constant miniaturization of electronic devices, aluminium CNC parts offer an attractive solution for producing intricate and lightweight casings and heat sinks. The growth of the consumer electronics market may drive the demand for aluminium components.

- Medical Applications: Aluminium’s biocompatibility and lightweight nature make it suitable for certain medical applications, such as prosthetics, medical devices, and equipment. As the medical industry advances, aluminium CNC parts could find more extensive use in this field.

- Infrastructure and Construction: The construction industry may increasingly adopt aluminium CNC parts for architectural features, façades, and structural elements due to their corrosion resistance, versatility, and aesthetic appeal.

- Defence and Military Applications: Aluminium’s strength-to-weight ratio and durability make it a valuable material for military equipment and vehicles. Further developments could enhance its role in defence applications.

In conclusion, the advantages of aluminium in various applications, combined with ongoing research and technological advancements, suggest a promising future for aluminium CNC parts across industries.

Recommended: Top 10 China Aluminum Machining Parts Manufacturers

The potential for growth lies in its lightweight, recyclability, corrosion resistance, and machinability, making it an attractive option for sustainable and innovative solutions in various sectors.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569