Description

[section]

[row]

[col span__sm=”12″]

Application Scope of Copper Parts

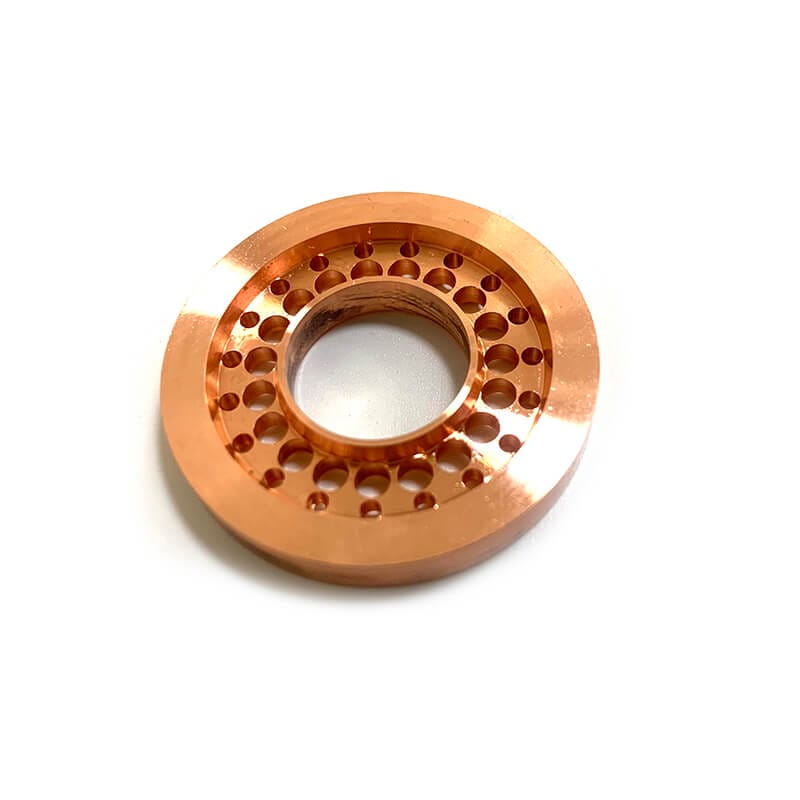

- Copper parts with high electrical conductivity: All kinds of electric power, telecommunication transmission cable; Various copper switches, connectors, busbars, electric brushes, rectifiers, motors, generators and copper transformers, sensors and so on; Various electrodes, resistors, capacitors, transistor unit, microwave devices, waveguide tubes, printing cylinders, copper integrated circuits lead frame, etc.

- Copper parts with high thermal conductivity: Power station, chemical, metallurgy, copper building heating, seawater desalination, car water tank and other heat exchangers; Condenser copper tube, duct piece, blast furnace cooling wallboard, copper mold casting, sensor water cooling coil, spacecraft propulsion, combustion chamber burner and so on.

- Copper parts with right strength: Bolts, copper nuts, washers, containers, hinges, rivets, caps, cover, copper brackets, gears and other structural parts.

- Copper parts with good corrosion resistance: All kinds of oil transportation, gas, vapor, water, or solution copper pipe; Building rainwater collection pipes, roof boarding; Valve, container, dam plate, hard copy.

- Copper parts have an elegant color: Architectural decorative plates, luminaires, copper sculptures, statues, trophies, boards, copper plates, clothing, and instruments.

- Copper parts have excellent antibacterial properties: drinking pipes, pipe fitting, tableware, kitchenware, living utensils, copper sorbet mold, and marine ship fender.

- Copper is non-magnetic: Copper shield.

Red Copper Application And Characteristics

Purple copper, also known as red copper, is copper elemental, because of its color for purple red named. See entry “copper” for various properties.

Red copper is industrial pure copper, its melting point is 1083℃, No allotropic transformation, relative density is 8.9, which is five times that of magnesium.

The mass of the same volume is about 15% heavier than ordinary steel.

Copper because of its rose red, the surface of the formation of the oxide film is purple, so generally called red copper.

It is copper containing a certain amount of oxygen, so it is also called oxygen-containing copper.

Red copper is a relatively pure type of copper, which can generally be approximated as pure copper.

It has good electrical conductivity and plasticity, but its strength and hardness are relatively poor.

Red copper is applicable in excellent thermal conductivity, ductility and corrosion resistance.

Trace impurities in red copper have a serious influence on the electrical conductivity and thermal conductivity of copper.

Among them, titanium, phosphorus, iron and silicon significantly reduce the electrical conductivity, while cadmium and zinc have little effect.

The solid solubility of sulfur, selenium and tellurium in copper is very small, and they can form brittle compounds with copper, which have little effect on electrical conductivity but can reduce machining plasticity.

Red copper has good corrosion resistance in the atmosphere, seawater, certain non-oxidizing acids (hydrochloric acid, dilute sulfuric acid), alkali, salt solution and a variety of organic acids (acetic acid, citric acid), and is used in the chemical industry.

In addition, red copper has good weldability and can be processed into a variety of semi-finished products and finished products by cold and thermoplastic processing.

In the 1970s, the production of red copper has surpassed the total production of all other copper alloys.

[/col]

[/row]

[/section]

[section]

[row]

[col span__sm=”12″]

Red Copper Parts Physical Properties

[row_inner v_align=”middle”]

[col_inner span__sm=”12″]

The trace impurities in red copper have a serious impact on the electrical conductivity and thermal conductivity of copper.

Among them, titanium, phosphorus, iron and silicon significantly reduce the electrical conductivity, while cadmium and zinc have little effect.

The solid solubility of sulfur, selenium and tellurium in copper is very small, and they can form brittle compounds with copper, which have little effect on electrical conductivity but can reduce machining plasticity.

When ordinary red copper is heated in a reducing atmosphere containing hydrogen or carbon monoxide, hydrogen or carbon monoxide can easily interact with cuprous oxide (Cu2O) at the grain boundary to produce high-pressure water vapor or carbon dioxide gas, which can crack the copper.

This phenomenon is often referred to as the “hydrogen disease” of copper.

Oxygen is harmful to the weldability of red copper. Bismuth or lead and copper form eutectic with a low melting point, which makes copper brittle.

The brittle bismuth is distributed along grain boundaries as a thin film made of copper brittle;

When the brittle bismuth is distributed in the grain boundary in the form of a thin film, it makes the copper cold and brittle.

Phosphorus can significantly reduce the electrical conductivity of red copper, but improve the fluidity of red copper liquid and improve weldability.

The proper amount of lead, tellurium, and sulfur can improve machinability.

The room temperature tensile strength of the annealed copper sheet is 22-25 kg/mm2, the elongation is 45-50%, and the Brinell hardness (HB) is 35-45.

[/col_inner]

[/row_inner]

The thermal conductivity of pure copper is 386.4 w/(m.k).

The use of red copper is much more extensive than pure iron, 50% copper is purified for pure copper by electrolysis every year, used in the electrical industry.

The red copper mentioned here really needs to be very pure, with a copper content of more than 99.95%.

A very small amount of impurities, especially phosphorus, arsenic, aluminum, etc., will greatly reduce the conductivity of copper.

Red copper is mainly used for the production of generators, busbars, cables, switching devices, transformers and other electrical equipment and heat conduction equipment such as heat exchangers, pipes, solar heating devices flat collectors.

Oxygen in copper (a small amount of oxygen is easily mixed during copper smelting) has a great impact on conductivity.

Copper used in the electrical industry must generally be oxygen-free copper. In addition, lead, antimony, bismuth and other impurities will make the crystallization of copper can not be combined together, resulting in hot brittle, which will also affect the processing of pure copper.

For this kind of high-purity copper, generally finished by electrolysis: Impurity copper (i.e. blister copper) was used as an anode, pure copper as a cathode and copper sulfate solution as an electrolyte.

When the current passes through, the impurity copper on the anode gradually melt, and the pure copper gradually precipitates on the cathode. The resulting copper is 99.99% pure.

Red copper is also used in the production of motor short-circuit rings, electromagnetic heating sensors, and high-power electronic components, wiring bar wiring terminals and so on.

Red copper is also applied to doors, windows, handles and other furniture and decoration.

YIJIN Hardware is an excellent turning and milling composite parts supplier. We are committed to providing customers with the most perfect CNC machining products and excellent CNC manufacturing services.

If you are interested in our products, you are welcome to send your requirements with your drawings to us via email. We are very glad to give you the most sincere service and the most favorable quotation.

[/col]

[/row]

[row]

[col span__sm=”12″]

Precision Machined Parts, 4-Axis CNC Machining

YIJIN Hardware Co., Ltd specializes in precision CNC Machining and provides OEM ODM service: CNC machining/Milling/turning parts, Casting Parts, Metal Stamping Parts, etc.

Mainly serves Aviation, Electronic products, Furniture, Health Care, Automotive, Communication, Automotive, Racing cars, and New Energy and infrastructure Enterprises. (such as high-speed trains and bridges.)

Material: Aluminum, Stainless Steel, Brass, Copper, Carbon Steel, Titanium alloy, Iron, Carbon Fiber, Plastic, Ceramic, Bamboo, Wood, Acrylic Etc.

Processing: CNC lathe, CNC milling and turning, grinding, bending, stamping, casting, etc.

Precision: The accuracy requirement is ± 0.002mm, and the finish requirement is Ra1.0μm.

Surface Treatment: Oxidation, hard Anodizing, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, etc.

There are many reasons why dozens of small, big and large-sized companies from across various industries have reposed their faith in Yijin Hardware for all their CNC Machine manufacturing and other allied services.

We offer some obvious advantages and benefits that are quite obvious and irrefutable:

- CNC

- We have a good track record as far as our products, spare parts and other such allied products are concerned. We have catered to some of the big names across the world.

- These companies are known for their strictest standards as far as quality and product specifications are concerned.

- We also offer top-class after-sales services and provide the required counseling and guidance before our clients choose our products. We offer both online and on-site services. This makes us stand apart from the rest of the crowd.

- Our rates and prices are competitive without compromising on quality.

- We have the right factories, R&D labs, and experienced and qualified staff to handle all types of needs of our customers.

Introduction Of CNC Machining Technology

We also would like to inform our readers that CNC Machining Technology including milling and turning is not easy.

It requires the right experience, the right machinery, the right environment and the right investment in technology. We are capable of offering all of them and are capable of meeting the high standards set by our clients.

What Advantages Do We Have In This Industry

Our biggest advantages are the fact that we are experienced and have our objectives clear.

We have a good team to take care of the specific and varying needs of our clients. We offer both readymade and customized solutions.

Our focus on research and our track record of catering to some of the most demanding customers across the world is a big advantage that not many of our competitors are able to offer.

Finally, we always have believed in adhering to the delivery schedules and timelines set by our customers and have very rarely failed to meet them.

Introduction Of CNC Processing Materials (Such As Wood, Iron, Steel, Plastic, Etc.)

We also would like to inform our customers that CNC processing is not material-specific.

It encompasses a wide range of materials covering steel, iron, plastic, wood and a host of other materials.

Each of them requires different types of machines, spare parts, electroplating and machining.

These materials are needed for making a wide range of commercial, industrial and domestic products.

[/col]

[/row]

[/section]

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569