10 Ways To Cut Stainless Steel Sheet

Cutting stainless steel is the process of cutting steel sheets into two or more parts. In steel cutting, the right

Yabian Community, Shajing Street, Baoan District, Shenzhen, China

Explore our core values and company events reflecting our dedication to excellence and innovation in CNC machining.

Get precise, reliable, and customized sheet metal fabrication services for your project. Our skilled team utilizes cutting-edge technology and industry expertise to deliver high-quality results. From design to production, we offer efficient turnaround times and competitive pricing. Send us a quick message to discuss us your sheet metal part design and get professional manufacturing advice.

YIJIN offers a wide range of custom sheet metal fabrication Services and products including precision sheet metal stamping parts, small metal stamping parts (3mm/6mm), metal stamping car parts, etc. View our gallery of custom sheet metal services to see our production capabilities.

We provide many specialized procedures as part of our custom sheet metal fabrication services to fulfill your individual needs. Below is the customized service we are providing now:

Laser cutting is a precise and versatile method for cutting sheet metal with the help of a high-powered laser beam.

This process allows for intricate and complex shapes to be cut accurately, with minimal heat-affected zones and high cutting speeds.

Laser cutting is suitable for most materials such as steel, aluminum, stainless steel, and others.

It is commonly used for applications that demand high precision, such as electronics enclosures, signage, brackets, and decorative panels.

Plasma cutting utilizes a plasma torch to cut through electrically conductive materials, including sheet metal.

Plasma cutting is an efficient and cost-effective technology for cutting thicker metal sheets, particularly steel.

It is extensively used automotive, construction, and metal fabrication industries.

Bending is a process that shapes sheet metal by applying force to deform it along a straight axis.

This is achieved using specialized machines such as press brakes.

Bending allows for the creation of various angles and complex geometries in sheet metal components.

HVAC (heating, ventilation, and air conditioning), automobile, aerospace, and appliance manufacturers all use it extensively.

Our bending services ensure precise and accurate bending, meeting your specific design requirements.

In addition to these core services, our custom sheet metal fabrication capabilities may also include other processes such as welding, punching, rolling, stamping, and finishing treatments like powder coating or plating.

We have a team of highly qualified engineers, designers, and fabricators who are able to work with you to understand your demands and create personalized solutions.

Please note that the availability of specific services may vary depending on the equipment and capabilities of our fabrication facility.

We can provide more details and discuss your project requirements to determine the most suitable fabrication processes for your needs.

Sheet metal fabrication services are the process of shaping, cutting, and alternating sheet metal to manufacture critical components and products.

It includes a wide range of techniques and processes, from prototype through manufacturing. Here’s a rundown of the major stages:

This stage focuses on creating a functional prototype of the desired sheet metal product. Before moving to full-scale production, prototypes are critical for testing and confirming the design. During this phase, engineers and designers collaborate to refine the product’s specifications and ensure it meets the intended requirements.

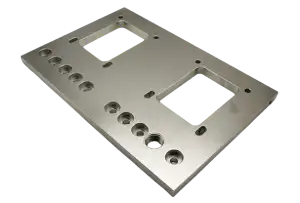

Rapid prototyping techniques utilize advanced technologies such as 3D printing and computer numerical control (CNC) machining to quickly fabricate prototypes. These techniques allow you to quickly test and validate designs, saving you time and money compared to other prototyping techniques.

Once the prototype is approved by the QC department, the production phase begins. On-demand production refers to manufacturing components or products in response to specific orders or customer demands. It offers flexibility, allowing for smaller production runs without requiring large upfront investments in tooling or inventory.

As one of the first engaged in the production of sheet metal parts in China, YIJIN Hardware provides ferrous and non-ferrous sheet metal production services with a custom sheet metal process.

Get high-quality custom sheet metal parts tailored to your needs and order directly from our factory to save time and cost.

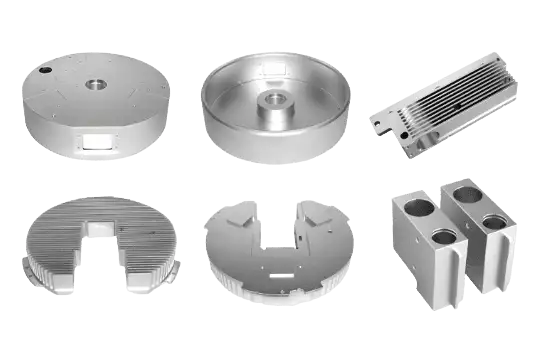

CNC machining technologies can be applied to a wide range of fields including the automotive, aerospace, consumer goods, medical, energy, optical communication, and robotics industries, etc.

Steel is a major element used as a material in sheet metal production because steel is strong and durable. Steel grades, such as carbon steel, stainless steel, and galvanized steel, differ in terms of strength, corrosion resistance, and appearance.

Aluminium is a high-strength, low-weight material with excellent corrosion resistance.It is commonly used in aerospace, automotive, and electronics industries. Aluminum is very easy to shape, weld, and machine. It comes in a variety of grades and finishes, giving you more design and aesthetic possibilities.

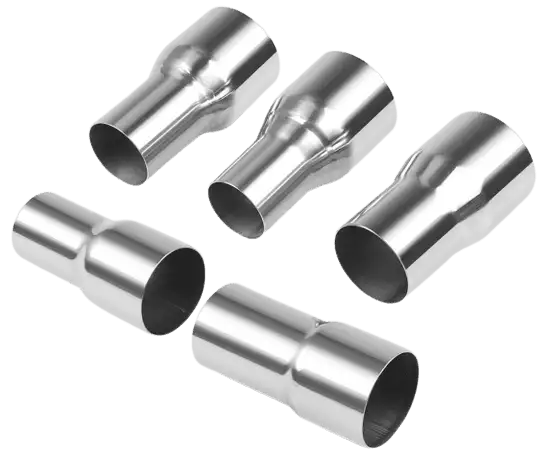

Stainless steel is highly corrosion resistant, making it ideal for applications requiring hygiene, such as food processing or medical equipment. It offers good strength, ductility, and a visually appealing finish. Various grades of stainless steel are available, each with specific properties, such as austenitic, ferritic, and martensitic stainless steel.

Copper is a very precise material with high thermal and electrical conductivity than any other material. It is commonly utilized in electrical components, heat exchangers, plumbing, and aesthetic applications. Copper is corrosion-resistant and easily manufactured and soldered. It develops a distinct patina over time, improving its overall appeal.

Brass is made up mainly of copper and zinc. It combines the aesthetic appeal of copper with improved machinability and corrosion resistance. Brass is often used in decorative applications, plumbing fixtures, musical instruments, and electrical connectors.

Nickel alloys, such as Inconel and Monel, are known for their superior corrosion resistance, high-temperature resistance, and strength. They are commonly utilized in aerospace, chemical industry, and maritime applications.

Sheet metal fabrication often involves the application of finishing techniques to enhance the appearance, durability, and functionality of the fabricated components.

Here are some common finishing options used in sheet metal fabrication:

The choice of finishing option depends on factors such as the desired appearance, functionality, environmental conditions, and budgetary considerations.

Fabrication service providers can provide guidance and expertise in selecting the most suitable finishing technique for specific sheet metal components or products.

Sheet metal is a comprehensive cold working process for thin metal sheets (usually below 6mm).

Sheet metal fabrication services are the process of shaping, cutting, and alternating sheet metal to manufacture various components and products.

The sheet metal fabrication techniques generally include blanking, bending, flanging, piercing, punching, embossing, coining, and stretching.

Due to its strength, adaptability, and low cost, Sheet metal fabrication services are widely used in the automotive, aerospace, and electronics industries.

The sheet metal fabrication process begins with the design and engineering phase, where the desired product or component is conceptualized and designed using computer-aided design (CAD) software.

Progressive stamping is required to produce metal parts with complex geometries.

The fabrication process begins once the design has been approved.

YIJIN provides various types of sheet metal fabrication services for your custom needs.

Yes, sheet metal can be painted or finished to enhance its appearance, protect it from corrosion, or meet specific requirements.

Common finishing options include powder coating, anodizing, plating, or applying protective coatings.

Sheet metal fabrication can be performed with various materials, including steel (mild steel, stainless steel, galvanized steel), aluminum, copper, brass, and more.

The choice of material depends on factors such as the desired strength, corrosion resistance, appearance, and the application of the final product.

Common sheet metal thicknesses range from 0.5 mm (0.020 inches) to 6 mm (0.250 inches) or more.

Thicker sheets may require specialized equipment and processes for cutting, bending, and forming.

Sheet metal processes can be performed on a variety of materials, whether ferrous (steel, carbon steel, etc.) or non-ferrous (aluminum, copper, etc.).

Find the proper materials from the list to build your custom sheet metal parts.

| 1. SPCC | SPCC (Cold Rolled Carbon Steel Sheets and Strips in full form) is a material grade that refers to commercial quality cold rolled steel. The surface of SPCC steel is exposed to the air and therefore easily oxidized. The humid environment will speed up the oxidation process and produce red rust. It’s suggested to use paint, electroplating, or other protective materials to protect the surface in use. |  |

| 2. SECC | SECC is a galvanized stamping material that is electrolytically coated with a zinc layer on the surface of the cold-rolled sheet. SECC features mechanical properties and similar processability as ordinary cold-rolled steel sheets with superior corrosion resistance and decorative appearance. This type of material is very popular on the market since it can make durable metal stamping parts for furniture, home appliances, and electronic products. The computer case is a typical application. |  |

| 3. SGCC | SGCC refers to hot dip galvanized steel material. It’s semi-finished material after hot pickling or cold rolling. After cleaning, annealing, and immersion in the melted zinc tank (at a temperature of about 460°C), the steel sheet is plated with a zinc layer. Quenching, leveling, and special chemical treatment are applied afterward to produce SGCC materials. SGCC material is harder than SECC material with poor ductility (avoiding deep pumping design), thicker zinc layer, and poor weldability. |  |

| 4. SUS 304 | SUS 304 is one of the most widely used stainless steel. It’s more corrosion and heat-resistant since it contains Ni (nickel) elements. It has good mechanical properties with no hardening phenomenon in heat treatments and no elasticity. |  |

| 5. SUS 301 | SUS 301 is less corrosion resistant due to its lower composition of the Cr (chromium) element. However, this material can obtain good tensile force and hardness in stamping processing with good elasticity after the cold working process. It is usually used for shrapnel springs and anti-EMI. |  |

Modern fabrication techniques, such as laser cutting and CNC bending, can achieve high levels of accuracy.

Laser cutting typically offers precision within a few thousandths of an inch (0.1 mm), while CNC bending can achieve accurate angles and dimensions within tight tolerances.

The specific accuracy depends on the capabilities of the fabrication equipment and the skill of the operators.

Sheet metal fabrication involves a range of processes to shape, cut, join, and finish sheet metal to create components and products. Here are some commonly used sheet metal fabrication processes:

| Processes | Description | Image |

Laser Cutting |

|  |

Water Jet Cutting |

|  |

Plasma Cutting |

|  |

Bending |

|  |

Cutting stainless steel is the process of cutting steel sheets into two or more parts. In steel cutting, the right

Sheet metal welding joins two metal sheets to make lightweight and durable structures. It’s used across industries from aerospace to

Metal part manufacturing is critical for various industries, from construction to automotive. Metal manufacturing uses techniques like forming, joining, molding,

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

Quick links

Contact

© 2024 Yijin Hardware. All rights reserved

WhatsApp us