Mechanical fixings are very important in manufacturing, which increases the use of different types of fasteners.

We have to choose among the different types of fasteners as per the nature of the work.

What are Fasteners?

“Fasteners – A kind of tool which is used for temporary fixing of things mechanically.”

Temporary Fastening: Fasteners are used for temporary fastening which helps in joining and disjoining different objects.

It helps us later when we need to change some object because it is quite easy to dismantle the temporary fastening rather than the permanent fastening such as welding.

Strength: The strength of the fasteners cannot be underestimated. It is a myth that they do not perform as strong as welding or soldering.

The issues happen because of some non-professional fastening. We have to carefully choose the types of fasteners according to the nature of the work.

We can use these types of fasteners reliably if the process of selecting and applying is done properly.

Importance: Fasteners have become one of the most important hardware tools these days.

Just take a glance at the objects around you. Almost every device or object you see consists of different types of fasteners which helped to build that object.

You name the device and it must consist of some types of fasteners. Fasteners help modern manufacturing in every aspect and get a special place in the hardware world.

Basic Types of Fasteners

1. Screws

Screws have a pointy edge which helps in penetrating the surface of the material and they also have helical threads throughout the surface which helps them to have the strength to hold anything.

Learn More: Different Types Of Threads | Parameters

Screws also consist of a head that comes with different kinds of designs. Different screwdrivers are used to install and uninstall them.

Different types of screws have different applications. The most used types of screws are:

- Sheet Metal Screws: These types of screws are used to install without drilling in the surface before. They have a sharper end and sharper threads which helps to make room inside the surface.

- Deck Screws: The deck screws are usually used outdoors and in the woods. They have a different driver design, which protects from corrosion to some extent.

- Masonry Screws: Masonry screws are similar to deck screws but are used in concrete such as walls. We have to use a drill and sometimes a washer uses it properly. Just like deck screws, they have a flat head as well.

- Machine Screws: Machine screws are used to fasten two objects or components of some product. They have no pointy edge but rather have a flat end. They have a uniform thickness because they have to offer a nice strength.

- Hex Lag Screws: Hex lag screws are heavy-duty screws that are used for intense loads. They are mostly used in connecting big machinery.

2. Nails

Nails were the most basic shape of the fastener which was formed in the early stages. They have a flat head and do not have any threads.

They are not as better as screws but they are the most famous among everyone. Households use them to fix almost everything in the house.

Different types of nails that are used in the market are:

- Brad Nails: These types of nails are the most important tool for carpenters. They are solely used in woods because they have this ability to blend into the material because of the very small head design which gets into the material.

- Common Nails: These are the nails that come in different sizes. They have a broader head which gives a greater holding power.

- Hoof Nails: Hoof nails are very unique and are used for horseshoes. They help a horseshoe to stay intact with the hoof.

- Roofing Nails: The short nails with a broader head are used for most of the roof-related tasks.

- Framing Nails: Such Nails are used in construction and are fired from a nail gun. They have a sharp point that is used to drive inside the surface of the material.

- Drywall Nails: These are another famous kind of nails that are usually used for installing drywalls. They have a smooth cupped head which helps them against the drywalls.

Learn More: Nail Size Chart | Nails Types

3. Bolts, Nuts, and Washers

These three types of fasteners are categorized together because in most cases they are used together.

- Cheese Head Bolts: These types of bolts have different kinds of heads. Has a cylindrical head which holds a greater strength.

- Hex Head Bolts: These are other types of bolts that hold great strength. They have a hexagonal head as their name which helps the spanners to tighten them easily. They are also available in huge sizes which are used in bridges and other building projects.

- Carriage Bolts: These types of bolts are also well known. They have a round-shaped head which helps in self-locking and doesn’t allow any loosing.

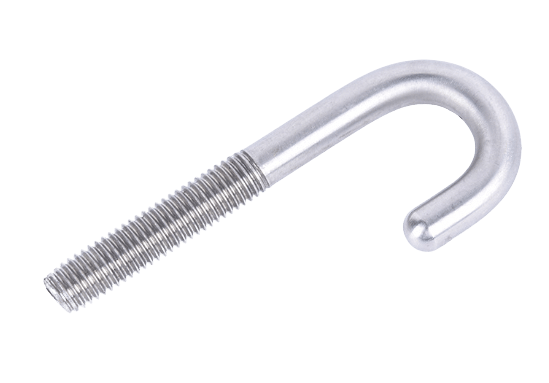

- Hook Bolts: These kinds of bolts have a bend at the end which helps in suspending anything with it.

- Headless Bolts: These bolts do not have any specific head. They have two ends so the nuts can be used on both sides. They are mostly used in surgeries for the fixation of broken bones and joints.

On the other hand, nuts are hexagonal-shaped metal blocks that have threads inside their body that are opposite to the bolts.

It helps bolts and nuts to join together which forms quite a nice connection.

A few examples of types of nuts are:

- Hexagonal Nuts: These types of nuts are hexagonal and can be fixed easily with the help of a wrench. They have threads on the inner side like other nuts.

- Flange Nuts: These types of nuts are the same as hexagonal nuts but have a pre-installed washer at one end which helps in reducing any loosing. Moreover, we do not have to add any washers as well.

- Cap Nuts: The cap nuts are closed from one of the ends. These nuts cover the edge of the bolts which gives a nice feel and protection. Wheel nuts are also an example of cap nuts.

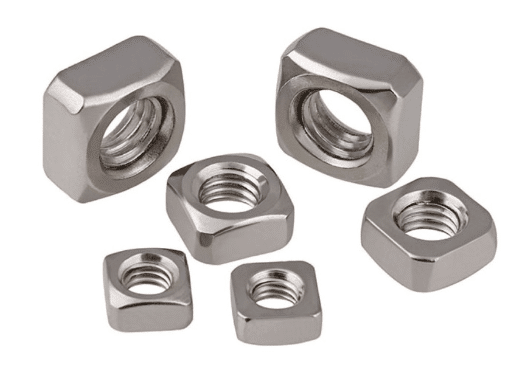

- Square Nuts: These nuts are square in shape. They are used where there is enough room as it takes more surface area. They are more reliable than hexagonal nuts.

- Ring Nuts: These nuts have a ring-like structure attached to one end. These nuts are being used where there is a regular need for losing or opening. This ring helps the users out there to easily place their fingers in them to unscrew them.

Washers are just like a disk with a hole inside them with the same diameter of bolts. They are placed between the head of the bolts and nuts.

They act as support that keeps the bolts from loosening.

A few examples of types of washers are:

- Flat Washers: They are the most simple and basic type of washers that support the bolts well. Learn More: When to Use A Flat Washer and When to Use A Spring Washer?

- Fender Washers: These washers are the same as flat washers but they have a larger diameter which helps in withstanding different metal sheets such as sign boards.

- Conical Washers: Conical washers are one of the most important types of users. Their edges are slightly tilted which helps as shock absorbers.

4. Anchors

Anchors are special types of bolts. They are called anchors because they have corners that embed them in the material and become almost impossible to get removed from the material.

They can only be removed by totally hollowing the material. Anchors are mostly used in concretes where they stuck themselves for the proper strength.

Some examples of anchors are:

- Sleeve Anchors: Sleeve anchors have an intelligent system that allows the base to expand when they are tightened in some material.

- Internally Threaded Anchors: They are used with some sort of bolts that are removed after the fixation. They are placed inside the material without being seen.

- Masonry Screw and Pin Anchors: Masonry anchors are anchors used to tighten or attach an item to the masonry which refers to anchors that are used in all types of masonry including concrete, brick, and block.

5. Rivets

Rivets are one of the permanent types of fasteners. Learn More: Types Of Rivets And Their Applications | An Overview. They have a unique kind of head and long smooth tails.

These tails can be expanded with some special tool and they are very reliable in comparison to other fasteners. They are more capable of supporting shear loads.

A few examples of types of rivets can be listed as:

- Blind Rivets: Such types of rivets are used where there is no room available at the other end so they make high-strength joints.

- Solid Rivets: These special kinds of rivets are mostly used in aircraft which help in assembling different parts of the aircraft.

- Split Rivets: These rivets have two tails and are mostly used in shoes and clothing.

Advantages

The fasteners have a few advantages and a few disadvantages as well. The advantages are as follows:

- No wastage of Materials

- Helping in designing

- Easy Maintenance

- Easy Installation

- Helps in Reducing Weight

Disadvantages

A few disadvantages of the fasteners are as follows:

- Corrosion

- Difficulty in Selection

Conclusion

Recommended: 2023 Top 10 Bolts And Nuts Manufacturers In China

There is a huge range of types of fasteners available which kept changing their shapes throughout the years.

There are plenty of sub-types in every type of fastener so the right choice becomes important.

We can conclude as we have to do our homework before using the different types of fasteners.

After installation, we should keep in our mind that maintenance is the most important part of making successful use of these types of fasteners.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569