What is A Thread?

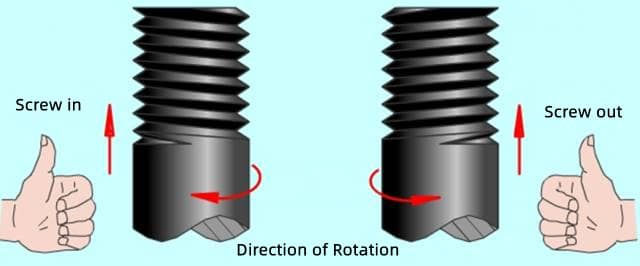

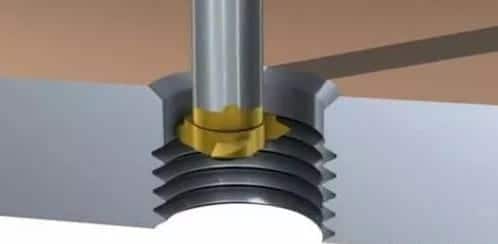

A thread is a surface that is created by the helical movement of a flat contour along a helical line. Due to these movements, the thread is formed.

A thread is a continuous helical ridge that can be created on the outside or the interior of a cylindrical surface. This is another definition of a thread.

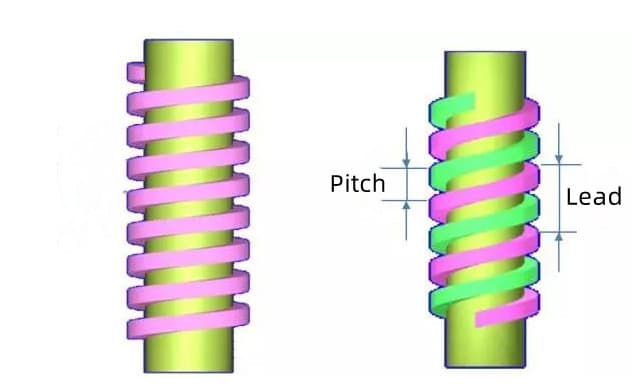

A screw is considered to be single-threaded if it has a single helical groove running down the body of the cylinder.

On the other hand, a screw is considered to be double-threaded if it has a second thread running in between the gaps of the first thread running along the body of the cylinder.

Different Types of Threads Across the World

Here, we’ll run down the 13 most common types of threads. The following thread types are organized by country. None of the types of threads on our list are in any particular order of significance.

ISO Threads

All measurements for ISO thread types are specified in millimeters. In ISO threads, the most common way to determine pitch is by taking the distance between the first and second teeth.

ISO Metric Thread (M)

In Europe, the ISO metric thread is one of the most common and popular types of threads. A normal thread is another name for this.

Each millimeter is one-tenth of an inch in diameter or pitch. M is the symbol representing the metric threading standard.

In addition, DIN 13 and DIN 14 provide detailed specifications for this thread type. The German standardization body is known as DIN.

Read More: Super Detailed–Metric Thread Sizes Chart

ISO Metric Fine Thread (MF)

When compared to its larger sibling, the ISO Metric Thread, the ISO Metric Fine Thread is very comparable. There, the flank angle is 60 degrees, and the code letters are MF.

The pitch is different, though, in both cases. In the watch industry, for instance, the metric fine thread is standard.

Steel Conduit Thread (Pg)

In electrical engineering, the steel armored pipe thread (Pg) is a historical thread described in DIN 40430.

Metric threads are gradually replacing it (DIN EN 50262). The armored pipe thread has an 80-degree flank angle.

Trapezoidal Thread (Tr)

Trapezoidal threads get their name because their profile looks like a trapezoid when viewed from above.

The trapezoidal thread is 30 degrees in flank angle and is labeled with the letters Tr. A total of three criteria exist.

The trapezoidal thread standard used by the International Organization for Standardization is described in DIN 103.

The trapezoidal thread profile used in DIN 380 is flatter. The rounded trapezoidal thread is standard in DIN 30295.

American Thread Types

Inches are usually used as the unit of measurement for American thread types (1 inch = 25.4 mm). Always, the angle of the flank is 60 degrees.

The pitch of the threads is the primary distinguishing feature of the various American unified types of threads.

Also presented in terms of threads per inch. A number of threads per inch are used to establish the pitch.

Unified National Coarse Thread (UNC)

The Unified screw thread, like the metric ISO thread, is a standard thread used mostly in the United States.

All measurements are done in inches, not centimeters. Similarly to the ISO thread, the flank angle is also 60 degrees.

Unified National Fine Thread (UNF)

Similarly, the Unified National Fine thread type is the equivalent of the ISO metric fine thread in the United States. The flank angle is also 60 degrees, like the UNC.

Unified National Special Thread (UNS)

When compared to other Unified threads, the pitch of the UNS variety is what sets it apart.

The flank angle is also 60 degrees in this case. Mic stands, among other things, employ this thread type.

National Taper Pipe (NPT)

National Taper Pipe (NPT) is a threaded standard for pipe fittings that is tapered or conical. As you can see, the flank angle is at a comfortable 60 degrees.

Self-sealing only occurs at low pressures, unlike NPTF.

National Taper Pipe Dryseal (NPTF)

Self-sealing and featuring a flank angle of 60 degrees, the NPTF is a tapered or conical pipe thread.

In contrast to the NPT thread, the internal and exterior threads of the metric thread overlap, allowing it to be self-sealing without the application of sealant.

British Whitworth threads

Sir Josep Whitworth is credited as the creator of the Whitworth thread. The British engineer standardized thread for the first time in 1841, which had an impact on the industrialization of thread manufacturing.

Whitworth thread size is given in inches, and its flank angle is 55 degrees. The United Kingdom is the world’s largest consumer of this particular thread.

British Standard Whitworth Coarse (BSW/ WW)

For one thing, the British Standard Whitworth is a screw thread, and for another, it’s a standard thread. A common shorthand for this is W or WW.

It functions and has the same meaning as the ISO metric thread standard. Having an angle of 55 degrees at the flank, it is measured in inches.

British Standard Fine (BSF)

One type of fine thread used in England is called British Standard Fine. Metric fine thread is equivalent in meaning and application.

The BSF thread has a 55-degree flank angle and is also stated in inches.

British Standard Pipe (BSP/ G)

The thread used in the British Standard Pipe is a Whitworth thread. This thread does not self-seal since it is cylindrical in shape. The letter G is used as an abbreviation.

There is one little quirk, though the inch specification does not match the inch diameter. For instance, one inch of British Standard Pipe (BSP) is equivalent to around 33.25 millimeters.

British Standard Pipe Taper (BSPT/ R)

When compared to the cylindrical internal thread of the British Standard Pipe Taper, the exterior thread of the former is tapered.

It is sometimes abbreviated as R (tapered male thread) and Rp (cylindrical female thread). It is self-sealing.

Detailed illustrations help you to distinguish thread types – pdf.

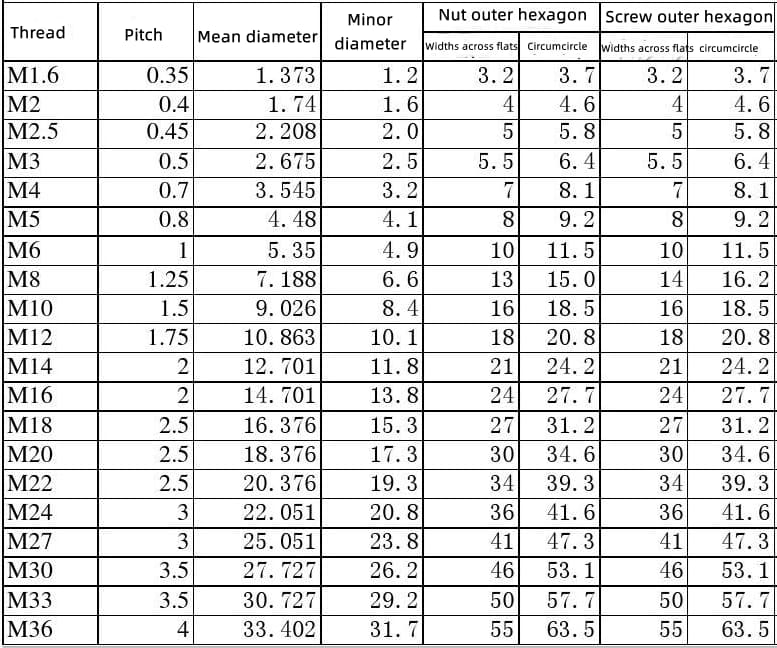

Thread Specification Table

Thread Parameters

The screw threads have specific names that are crucial to know and are detailed further down in this article for your convenience.

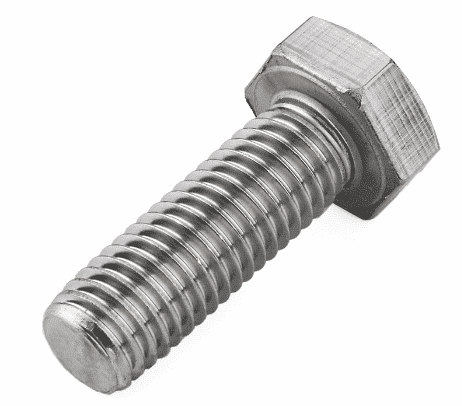

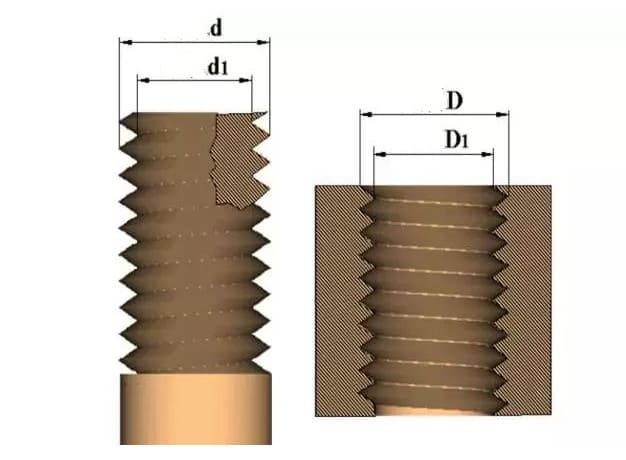

Major Diameter

The greatest diameter of any screw threads, whether they be internal or exterior, is referred to as the major diameter.

The major diameter of an external thread is the same as the exterior diameter of the thread, whereas the major diameter of an inner thread is the same as the diameter of the thread from the inside. It may also be referred to as the nominal diameter or the outer diameter.

Minor Diameter

The term “minor diameter” refers to the screw thread with the lowest diameter, which might be internal or exterior.

The minor diameter refers to the outer thread diameter for external threads and the inner thread diameter for internal threads.

For exterior threads, the minor diameter refers to the inner thread diameter. The minor diameter is also referred to as the route or the diameter at times.

Pitch Diameter

The term “pitch diameter” is synonymous with the term “effective diameter.” Pitch diameter is the imaginary dimension on a cylindrical screw thread that will pass through such locations to produce the equal width of gaps and width of threads.

This diameter is designated as the pitch diameter. It is the most likely place where the internal and external threads may interact with each other.

Pitch

The distance between the corresponding point of one thread to the corresponding position of the next thread is referred to as the pitch.

The pitch is expressed mathematically as The pitch is measured in millimeters, and its definition is:

Pitch = 1/number of threads per unit length of the screw

Thread Per Inch (TPI)

The term “thread per inch” refers to the number of threads that are produced in a length of one inch along the axis of rotation or the length of the threads that are produced in the same axial plane on one side of the axis of rotation. It is the primary and universal parameter that is used by all different types of threads.

Lead

The lead is measured in terms of the distance between two places on the same helix that correspond to one another.

In the case of threads with a single start, the pitch is the same as the lead; however, in the case of threads with a double start, it is twice the pitch; in the case of threads with a triple start, it is thrice the pitch; and so on.

Conclusion

These were the 13 most significant types of threads that you ought to be aware of. Do you have any questions or suggestions?

Are you missing a thread type that is important to you? We would appreciate it if you would get in touch with us or leave a comment if you have any questions.

Recommended: An Ultimate Guide To American Fastener Sizes

Recommended: 2023 Top 10 Bolts And Nuts Manufacturers In China

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569