Looking to manufacture something custom in China but don’t know where to start? It’s challenging to pick from so many machine shops.

But take a deep breath – this blog post will guide you on how to find an amazing CNC shop to get your project done right.

Lots of businesses face the problem of finding reliable Chinese manufacturers. It is very important to know what specifics to look for so you can make a smart choice.

We’ll break down must-have qualities to help you find shops that fit your needs. That way you can feel confident you’ll get top-quality work and amazing results!

What are CNC Machine Shops?

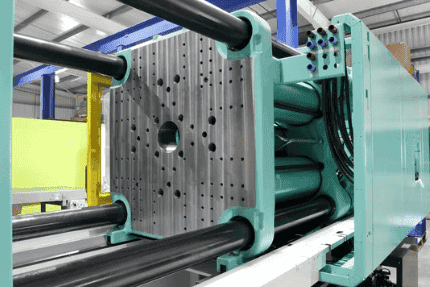

A CNC machine shop is a manufacturing workshop that depends on computer numerical control (CNC) machines to make custom parts needing really precise shapes and sizes.

These modern shops play a huge role in manufacturing by offering CNC machining services across sectors like aerospace, automotive, medical, and more.

As technology has moved forward, CNC machine shops have upgraded too, with cutting-edge equipment and methods. This allows them to take on tricky projects and achieve outstanding results.

Today’s CNC manufacturing shops have a wide variety of CNC machines available for use like lathes, mills, specialized tools, etc. This means they can serve many different customer needs.

These metal machine shops have advanced equipment to work with all kinds of metals and mixes, ensuring excellent quality results for all sorts of industries. That’s why they’re so important in manufacturing nowadays.

What Kinds of Equipment Do Top CNC Machine Shops Have?

When you visit a high-end CNC shop, you’ll find all kinds of fancy machines to meet different needs. Let’s check out some common things these workshops have for machining and finishing parts.

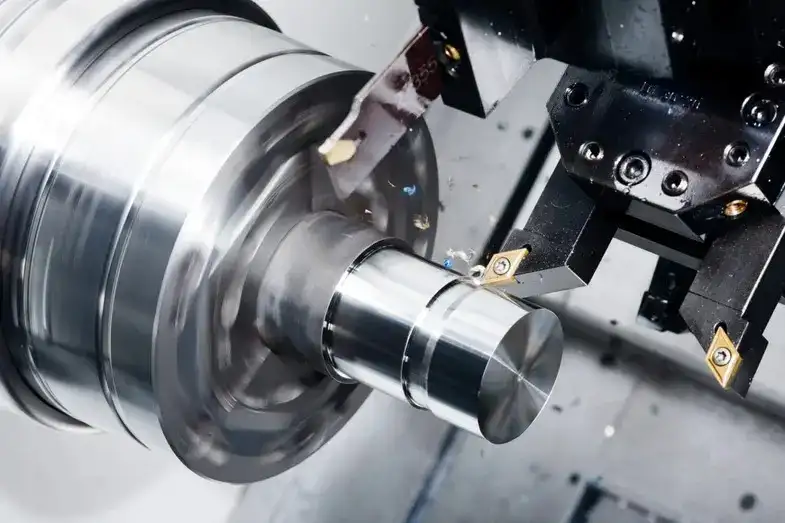

CNC Turning

Ever heard of CNC turning or CNC lathes? This process clamps the workpiece on a spindle and rotates it. As it spins, a cutting tool shaves off material to cut cylindrical and round shapes.

It’s commonly used for making shafts, bushings, and other circular components with incredibly high precision.

CNC Milling

Next is milling! This flexible machining approach uses rotary cutters that carve into workpieces to remove material. With CNC milling machines, complex 3D forms, contours, and holes can be crafted in all sorts of materials. 3-axis, 4-axis, and 5-axis CNC mills allow intricate aerospace, automotive, and medical parts to be produced.

CNC Drilling

CNC drilling is a major advancement in high-precision manufacturing. It works by using a rapidly spinning drill bit to cut round holes into the workpiece.

CNC drilling machines are super accurate and can repeat the same hole over and over. This makes them perfect for producing large batches of parts where each one needs to match others flawlessly.

Grinding Machines

Next are grinding machines. These are used as finishing steps to get ultra-tight tolerances and smooth surfaces. They carefully shave off tiny bits of material using a sharp grinding wheel.

This polishing after initial CNC machining brings out the best finish for your part.

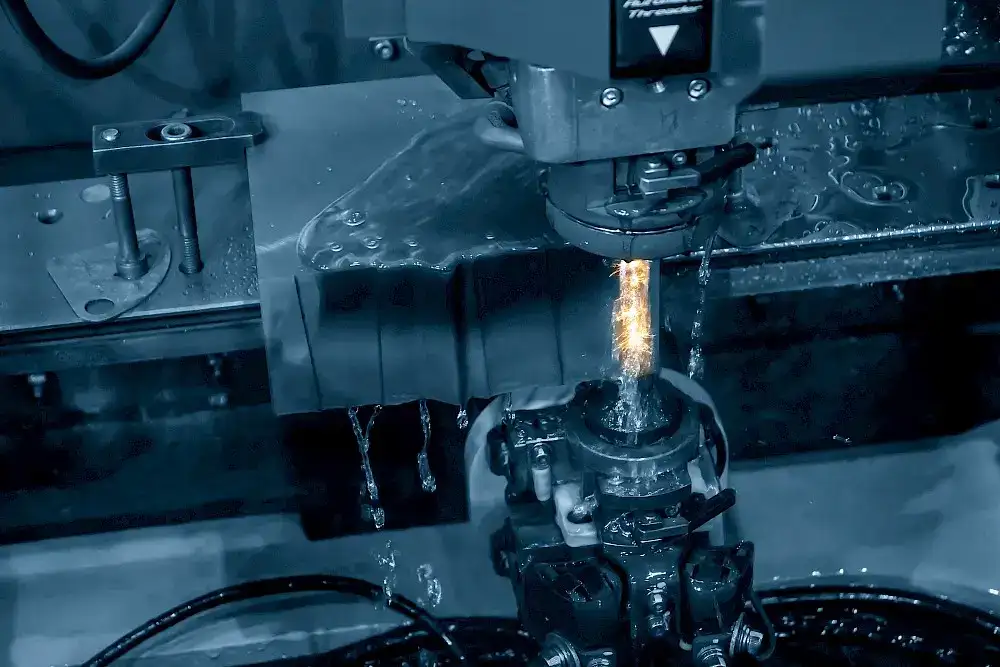

EDM and EBM Machines

Then CNC machining shops have EDM (Electrical Discharge Machining) and EBM (Electron Beam Machining). These advanced processes use electrical energy to remove material without contact.

EDM uses sparks to remove complex shapes. EBM melts or vaporizes material using a concentrated electron beam. Both can craft intricate, high-accuracy parts out of tough metals.

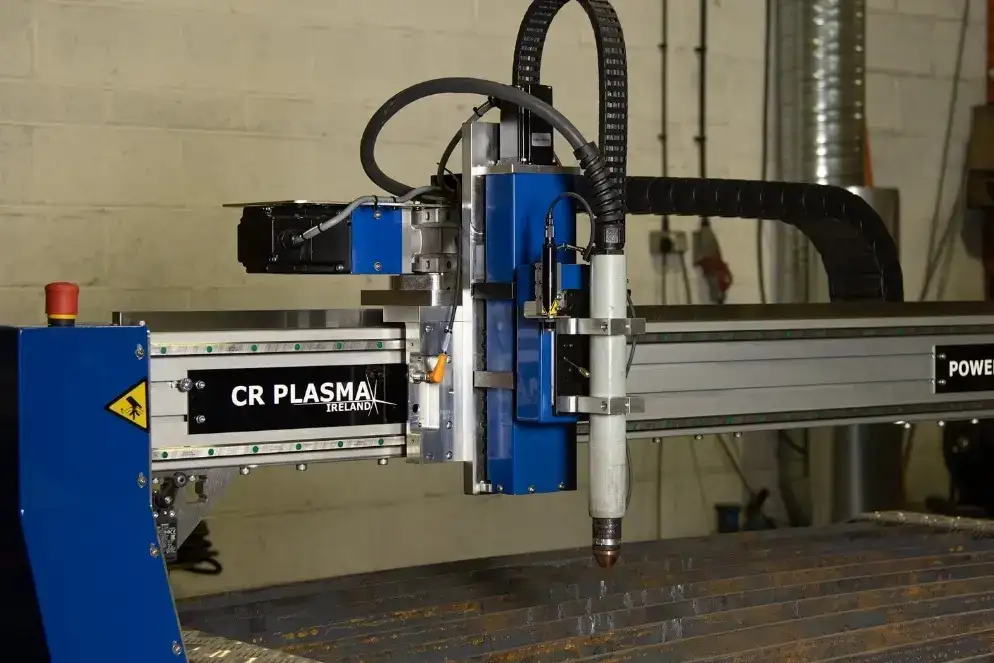

Plasma Cutting Machines

Plasma cutters use super-fast moving hot ionized gas to slice through conductive materials like metals. They can cut complex shapes quickly, so they’re great for pumping out high volumes of intricate parts.

Water Jet Machines

Water jets shoot out a thin stream of high-pressure water mixed with abrasive bits to carve through all kinds of materials like metals, plastics, composites, and more.

Cutting itself doesn’t generate any heat, so water jets are excellent for gently cutting fragile or heat-sensitive stuff.

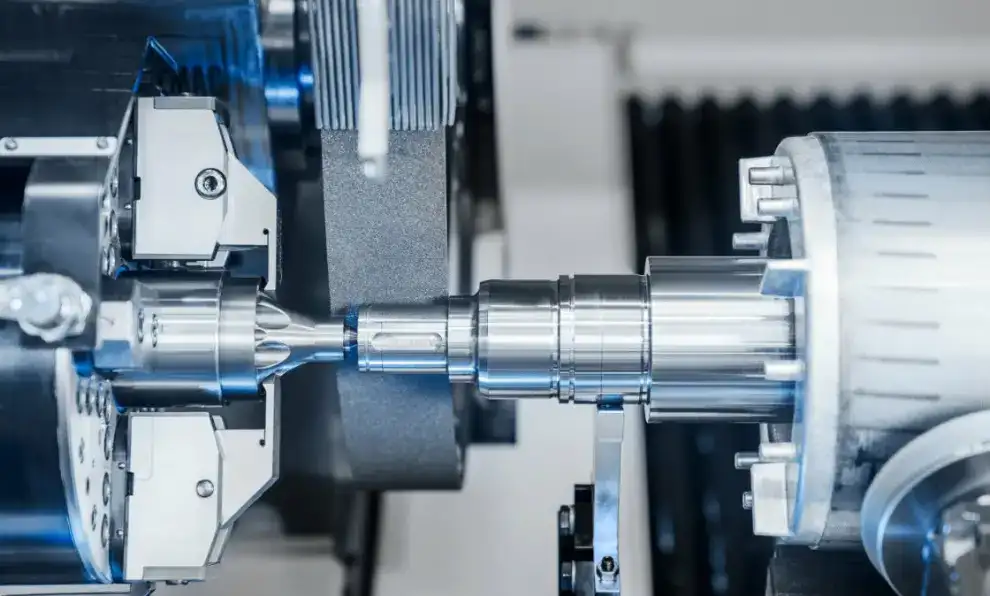

Swiss Machine

Swiss machines are also called Swiss-type lathes. These are advanced CNC turning machines that are made specially to produce tiny, super precise parts.

Swiss machines have incredible accuracy and consistency. That makes them perfect for manufacturing little components used in medical gear, aerospace, or electronics.

Surface Finishing Tools

A reputable CNC shop better has plenty of gear for enhancing the look and feel of machined parts. We’re talking about polishers, buffers, anodizes, electroplaters, coaters, or any other technique needed to give parts that are polished, coated, plated, anodized, or other surface finish.

Quality Control Equipment

Strict quality control is very important for manufacturing accurate, consistent machined parts. A truly excellent CNC shop will have advanced quality check gear like Coordinate Measuring Machines (CMM).

CMMs precisely scan and examine freshly machined parts to verify they match the original CAD model dimensions without any variation. That’s how you guarantee parts are made to specification.

How do CNC Machine Shops Manage Quality Control?

To produce parts that meet specifications and standards, top CNC shops have hardcore quality control across the machining process. Let’s check these quality checkpoints throughout the CNC machining process.

-

Raw Material Inspection

Before any machining begins, it’s important we thoroughly examine all raw materials to catch issues early. We confirm the grade, dimensions, and existing flaws of metals and other stock are correct. Doing diligent raw material checks keeps problems from appearing later during the machining process.

-

In-Process Inspection

CNC machine shops use various techniques to check the quality of parts as they make them. They might use in-process gauging systems, visual inspections, and statistical process control (SPC) techniques. This lets them catch and fix mistakes quickly. It cuts down on waste and keeps quality consistent.

-

Post-Processing Inspection

After making parts, CNC machine shops do one final check. They might use high-tech tools like coordinate measuring machines (CMMs) to make sure the parts are of the right size. They can also check how smooth surfaces are, test hardness, or use non-destructive testing (NDT) methods, like ultrasonic testing or X-ray inspection. Doing these detailed checks helps ensure that all parts meet necessary quality levels before sending them off to customers.

Materials Used in CNC Machining

When it comes to CNC machining, picking the right material matters just as much as design and manufacturing itself. A top-quality CNC machine shop will have a wide range of metals, plastics, and composites to meet all types of custom project needs.

- Metal Material: Aluminum Alloy, Copper Alloy, Carbon Steel, Stainless Steel, Titanium.

- Plastic Material: Engineering plastics like PEEK, PC, POM, PP, Nylon, PMMA, ABS, Teflon, PVC, etc.

- Composites: Reinforced plastics, ceramics, carbon fiber, etc.

Learn More: CNC Machining Materials: Which Is Best For Your Project

Choosing the perfect material is very important for getting the properties and performance you want in your finished product. Whether it’s the strength and durability of metals or the flexibility and corrosion resistance of plastics, what you make parts from, directly affects how well they function and last.

How to Choose A CNC Machine Shop?

Picking the right CNC machine shop for your project is essential for getting quality work, on-time delivery, and staying on budget. Here’s what to look out for in CNC machining service providers:

Experience and Expertise in Your Specific Industry

Choose a CNC machine shop that has deep knowledge about your field. They should thoroughly understand what your sector demands regarding standards, regulations, and unique challenges. This way, they can produce parts that exactly match what you need.

Range of Services Offered

Look at the services the CNC machine shop provides. Whether your project is about creating prototypes, running small batches, or pushing large volumes, the CNC machine shop should be able to complete your task properly. A multi-skilled workshop can support all phases of your projects now and later on.

Quality Control Certifications

Pick a CNC shop with important quality seals like ISO 9001 certification. These seals prove that the company is committed to holding their manufacturing process to high, consistent standards. An ISO-certified CNC machining provider gives assurance regarding manufactured part quality.

Turnaround Time and Flexibility in Order Sizes

Review the shop’s speed in delivering orders and range of order sizes. They should meet lead times whether you need a fast prototype or a high-volume production run. Flexibility in quantities allows for increased production as required without quality or timing compromises.

Proven Track Record with Testimonials or Case Studies

Choose a shop with a proven background of success. Check out testimonials, case studies, or references from past clients to measure their satisfaction and work quality. A solid CNC machining provider will showcase a portfolio of wins and happy customers.

Communication and Customer Service Quality

Having open lines of communication and stellar customer service are must-haves when partnering with a CNC shop. They should be responsive and upfront in updating you at every stage. Having a dedicated main contact ensures smooth teamwork and answers to any questions you’ve got.

Technological Capabilities and Machinery

Evaluate the CNC shop’s tech and equipment. They need cutting-edge CNC machines, like multi-axis milling and turning centers, to take on complex shapes and nail tight precision standards. Advanced technologies like 5-axis CNC machining can allow greater creative freedom in design and improved efficiency.

Confidentiality and Intellectual Property Protection Measures

When outsourcing CNC work, protecting your intellectual property and confidentiality is crucial. Choose a shop that has strict security rules and non-disclosure agreements (NDAs) to safeguard your designs, data, and proprietary information.

Tips for Picking CNC Machine Shops in China

- Ask to see samples or test products. Having the shop show you some parts they’ve made before helps you directly judge their quality and skill level.

- Visit in person, if you can. Seeing the facility and its whole operation with your own eyes is invaluable. You can check out their equipment, processes, professionalism, and more.

- Make sure they have certifications and follow international standards. Depending on your specific industry, look for shops with certifications like ISO or AS9100. This helps ensure quality.

- Check for online reviews and customer feedback. Hit the forums, industry sites, or shop’s testimonials section. Real-life experiences from past clients give great insight into things like responsiveness, dependability, and satisfaction rates.

CNC Machine Shop in Yijin Hardware

Shenzhen Yijin Hardware Co. Ltd. has been a leading CNC machine shop in China since 2003. Our company focuses on making precise parts for many sectors of industry. We have large facility of 25,000 square meters and 100+ skilled workers.

Yijin Hardware can do various CNC machining tasks such as turning, milling, and drilling. We have a total of 887 machines. This includes 136 high-precision CNC machining centers, 278 CNC lathes, and 277 three-axis and five-axis machining centers. These top-quality machines can produce complex parts with great quality for the aviation, medical, automotive industries, and many more.

With its advanced tools and talented experts, Yijin Hardware stands out not only for mass manufacturing but also as one of China’s best prototype machine shops, assisting customers in swiftly and efficiently transforming their concepts into reality.

Yijin Hardware uses 281 sets of testing gear such as Zeiss CMM and hardness testers to make sure every project meets strict standards.

Yijin Hardware works closely with clients worldwide to design and create top-quality parts. Our focus is on innovation, precision, and customer happiness making them the top choice in China for custom CNC projects.

To learn more about Yijin Hardware or start a project with them, visit our website Yijin Hardware. Our team is ready to offer top solutions for any unique CNC machining needs you have.

Conclusion

Choosing the right CNC machine shop is make-or-break for custom manufacturing projects. We’ve talked about why it’s so important to partner with a shop that’s got strong experience, great facilities, and serious quality control – especially when working overseas in China’s huge manufacturing industry.

Modern shops have advanced equipment like CNC mills, lathes, and presses. Top shops back up quality work with certifications like ISO.

When reviewing options, important factors should be checked out, like How long their track record is. What’s their specialty – what services do they offer? Do they have rigorous quality standards and testing?

How fast can they deliver? Do they communicate well? Are they using the latest technology? The more effort you put in here, the better your custom parts will turn out.

Yijin Hardware stands out as a leading CNC machining service provider in China. For businesses that want high-quality, reliable, and cost-effective CNC solutions, Yijin meets every requirement.

They’ve got experience, capabilities, and commitment to quality that makes a shop truly reliable.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569