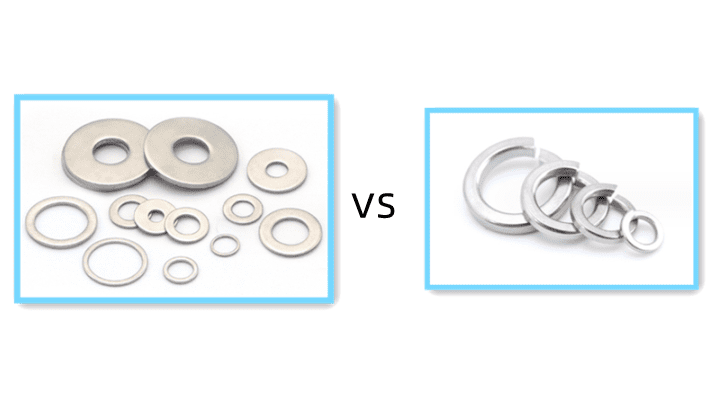

In the world of fasteners and hardware, the choice between flat washers and spring washers can have a significant impact on the integrity and reliability of your connections.

This guide explores the differences between these two essential components, offering insights into their applications, advantages, and best practices to help you make informed decisions when selecting the right fasteners for your specific needs.

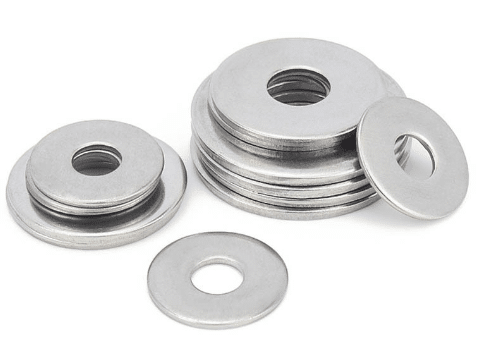

Flat Washers: Enhancing Stability and Distribution of Load

In this section, we’ll delve into the intricacies of flat washers, exploring their detailed characteristics, applications, types, and the benefits they bring to the world of secure connections.

Describing Flat Washers in Detail:

Flat washers, also known simply as washers, are thin, flat, and circular discs with a central hole. They come in a variety of materials, including metals like stainless steel, brass, or zinc-plated steel, as well as plastic.

The design is minimalistic, but its function is profound. These unobtrusive components serve as a buffer between the fastener (bolt or screw) and the material it’s securing, ensuring the even distribution of the load applied.

When and Why They Are Used:

Flat washers find their application across a wide range of scenarios, but their usage is particularly crucial in the following situations:

- Load Distribution: When the load from a fastener needs to be spread over a wider surface area, flat washers are essential. They prevent the fastener from digging into or damaging the material, ensuring the material’s integrity.

- Preventing Over-Tightening: Flat washers help prevent over-tightening, which can deform the material or compromise the connection’s integrity. They ensure that the clamping force is evenly distributed, enhancing the overall reliability of the connection.

Various Types of Flat Washers:

Flat washers come in several types, each tailored to specific applications. Some of the common variants include:

- Plain Flat Washers: These are the most basic type, featuring a simple, flat, and smooth surface. They’re ideal for general-purpose load distribution.

- Fender Washers: Fender washers have a larger outer diameter, which provides better load distribution. They are commonly used in automotive and marine applications, particularly for fender installations.

[row]

[col span=”1″ span__sm=”12″]

[/col]

[col span=”10″ span__sm=”12″]

[ux_video url=”https://youtu.be/BpdVqdGa8fI”]

[/col]

[col span=”1″ span__sm=”12″]

[/col]

[/row]

Benefits of Using Flat Washers:

The use of flat washers offers several benefits:

- Enhanced Stability: By evenly distributing the load, flat washers increase the stability and reliability of connections, preventing material damage and ensuring a longer lifespan for the fastened components.

- Material Protection: They protect the material being fastened from damage, whether it’s wood, metal, or other substrates, by acting as a buffer between the fastener and the material.

- Consistent Clamping Force: Flat washers ensure that the clamping force is uniformly applied, reducing the risk of over-tightening and promoting connection integrity.

In essence, flat washers, with their simple yet effective design, play a vital role in maintaining secure and durable connections in numerous applications.

Whether it’s in construction, woodworking, or any industry that relies on fastening, understanding when and how to use flat washers is key to ensuring the longevity and reliability of your projects.

Spring Washers: Ensuring Tension and Reliability in Fastening

Spring washers, often characterized by their distinctive designs, are indispensable components in the realm of fastening.

This section provides a comprehensive overview of spring washers, including their detailed attributes, applications, types, and the advantages they bring to the world of secure connections.

Describing Spring Washers in Detail:

Spring washers exhibit a unique, spring-like design, typically taking the form of conical or wave-shaped discs.

Their defining feature is their ability to flex and exert tension under pressure, which sets them apart from flat washers.

This spring effect is essential to their function, allowing them to maintain tension in fastener assemblies.

When and Why They Are Used:

Spring washers find their niche in fastening applications where maintaining tension is crucial. They are particularly valuable in the following scenarios:

- Vibration Dampening: In situations where fasteners are exposed to vibrations, such as in automotive, machinery, or equipment assemblies, spring washers are used to prevent self-loosening. The spring effect ensures that the fastener remains securely in place, even under continuous vibration.

- Thermal Expansion and Contraction: Spring washers are employed in applications where temperature fluctuations cause materials to expand and contract. These washers compensate for these changes, maintaining consistent tension in the connection.

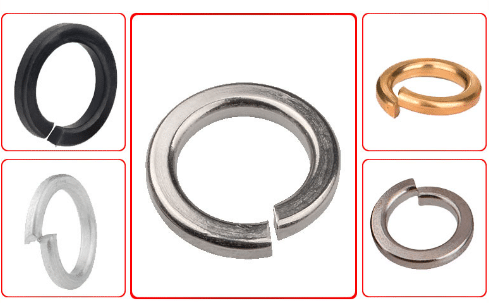

Various Types of Spring Washers:

Spring washers come in various types, each designed for specific applications. Some of the common variants include:

- Split Lock Washers: These washers have a split design that allows them to exert tension when compressed. They are commonly used to prevent nuts and bolts from coming loose due to vibrations.

- Belleville Washers: Belleville washers, also known as conical spring washers, have a conical shape that enables them to provide high spring rates and load capacities. They are often used in heavy machinery and automotive applications.

Benefits of Using Spring Washers:

The use of spring washers offers several benefits:

- Tension Maintenance: Spring washers excel at maintaining tension within the fastener assembly, ensuring that the connection remains secure over time. This is vital in applications where self-loosening or slackening could be dangerous or costly.

- Vibration Resistance: They are highly effective in countering the effects of vibrations, preventing fasteners from backing out due to external forces. This is especially important in scenarios where machinery or equipment reliability is paramount.

- Consistent Clamping Force: Spring washers provide a reliable and consistent clamping force, even in environments with frequent temperature fluctuations, ensuring the longevity and reliability of the connection.

In summary, spring washers, with their unique spring-like design, are essential for maintaining tension and preventing self-loosening in fastening applications.

Whether it’s in automotive, heavy machinery, or other industries where stability and reliability are crucial, understanding when and how to use spring washers is key to achieving secure and durable connections.

Flat Washers vs. Spring Washers

Understanding the differences between these two essential pieces is crucial for making informed decisions in fastening applications.

Here, we’ll provide a side-by-side comparison, highlighting the variances in their design, function, and ideal applications.

Design Differences:

Flat Washers:

- Simple and Flat: As the name suggests, flat washers are typically flat, circular discs with a central hole. Their design is minimalist and straightforward.

- Material Variety: Flat washers are available in various materials, including metals like stainless steel, brass, and plastics. This diversity allows for compatibility with a wide range of applications.

Spring Washers:

- Spring-Like Structure: Spring washers feature a unique spring-like design, often conical or wave-shaped. They are built to flex and exert tension under pressure, which sets them apart from flat washers.

- Material Flexibility: Spring washers are typically constructed from materials that exhibit elasticity, such as spring steel. This elasticity is integral to their function.

Functional Differences:

Flat Washers:

- Load Distribution: Flat washers are primarily used to evenly distribute the load applied by a fastener. This helps prevent damage to the material being fastened and ensures that the clamping force is uniformly applied.

- Material Protection: They act as a buffer between the fastener and the material, safeguarding it from deformation or damage due to over-tightening.

Spring Washers:

- Tension Maintenance: Spring washers are designed to maintain tension within the fastener assembly. They excel at preventing self-loosening due to vibrations, thermal expansion and contraction, or other external forces.

- Vibration Resistance: They are particularly effective in applications exposed to vibrations, where their spring effect counteracts the tendency of fasteners to back out.

Application Differences:

Flat Washers:

- General Load Distribution: Flat washers are commonly used in a wide range of applications, including construction, woodworking, and general fastening tasks where load distribution is essential.

- Material Protection: They are ideal for scenarios where the goal is to protect the material being fastened from damage or deformation.

Spring Washers:

- Vibration-Prone Environments: Spring washers find their niche in applications where self-loosening due to vibrations is a concern, such as in automotive, machinery, and equipment assemblies.

- Thermal Variations: They are valuable in situations where temperature fluctuations cause materials to expand and contract, necessitating the maintenance of consistent tension in the connection.

How to Select the Right Washer

The choice between flat washers and spring washers boils down to the specific requirements of your fastening project.

When load distribution and material protection are paramount, flat washers are the go-to solution. However, in scenarios where maintaining tension and preventing self-loosening due to vibrations or thermal fluctuations is critical, spring washers take the lead.

By understanding the key differences and considering your application’s unique needs, you can confidently choose the right washer for a secure and reliable connection.

When to Use Each Type: Making Informed Washer Choices

Selecting the right type of washer for your fastening application is crucial for ensuring the longevity and reliability of your connections.

In this section, we’ll offer guidance on when it’s appropriate to use flat washers and provide insights into the situations where spring washers are more effective.

We’ll also share practical examples and industry-specific recommendations to help you make informed washer choices.

When to Use Flat Washers:

Flat washers are your go-to choice in the following scenarios:

- Load Distribution: Whenever the primary objective is to distribute the load evenly across a fastener and the material it’s securing, flat washers are indispensable. This is particularly important when you want to prevent material damage or deformation due to localized pressure.

- Protecting Materials: Flat washers serve as protective buffers, making them ideal for scenarios where you want to shield the material being fastened from harm. Whether you’re working with wood, metal, or any other substrate, flat washers help maintain the material’s integrity.

- General Fastening Tasks: Flat washers are versatile and find applications in a wide range of industries, including construction, woodworking, plumbing, and general fastening. They are especially useful in everyday projects where load distribution and material protection are essential.

When to Use Spring Washers:

Spring washers shine in the following situations:

- Vibration-Prone Environments: Spring washers are highly effective in applications exposed to vibrations. These can include automotive and machinery assemblies, where maintaining a secure connection despite continuous vibrations is a top priority. Spring washers prevent self-loosening and ensure connection integrity.

- Thermal Variations: In environments where temperature fluctuations cause materials to expand and contract, spring washers are the preferred choice. Industries like aerospace, where extreme temperature changes are common, benefit from the tension-maintaining capabilities of spring washers.

- Critical Machinery: Applications involving heavy machinery, industrial equipment, and critical components often require the use of spring washers. These washers ensure that fasteners remain securely tightened, reducing the risk of downtime or equipment failure.

Practical Examples and Industry-Specific Recommendations:

- Automotive: In the automotive industry, where vibrations and temperature fluctuations are frequent, spring washers are essential for ensuring the reliability of critical connections, such as engine components and suspension systems.

- Construction: When building structures, using flat washers in combination with bolts is common to distribute the load and protect construction materials. However, in situations where heavy machinery is involved, such as cranes or heavy equipment, spring washers may be employed to withstand vibrations.

- Aerospace: The aerospace industry relies heavily on spring washers to maintain tension in fasteners due to extreme temperature variations during flight. Flat washers are used for less critical applications.

The choice between flat washers and spring washers depends on the specific requirements of your project.

Understanding the nuances of their applications and considering factors like load distribution, material protection, vibrations, and temperature fluctuations will help you make the right washer choice, ensuring the safety and reliability of your connections.

Pros and Cons of Flat Washers and Spring Washers: Making Informed Choices

Flat Washers:

Advantages of Using Flat Washers:

- Load Distribution: Flat washers excel at evenly distributing the load applied by fasteners. This helps prevent material damage and ensures connection integrity.

- Material Protection: They act as a protective barrier between the fastener and the material, shielding it from deformation or damage caused by localized pressure.

- Versatility: Flat washers are incredibly versatile and find applications in a wide range of industries and projects. They are suitable for general-purpose load distribution.

Disadvantages of Using Flat Washers:

- Limited Tension Maintenance: Flat washers do not possess the ability to maintain tension in fastener assemblies. This can be a drawback in applications where preventing self-loosening is crucial.

- Not Ideal for Vibration-Prone Environments: In scenarios with continuous vibrations, flat washers may not offer the level of security required, as they lack the tension-maintaining capabilities of spring washers.

Spring Washers:

Advantages of Using Spring Washers:

- Tension Maintenance: Spring washers are specifically designed to maintain tension within the fastener assembly. This makes them ideal for preventing self-loosening due to vibrations, temperature fluctuations, or external forces.

- Vibration Resistance: They are highly effective in applications exposed to vibrations, making them a preferred choice in industries like automotive and machinery, where reliability is paramount.

- Temperature Variations: Spring washers perform well in environments where materials expand and contract due to temperature variations, such as in aerospace applications.

Disadvantages of Using Spring Washers:

- Limited Load Distribution: Spring washers do not excel at load distribution. In fact, they may not provide as even a distribution as flat washers, making them less suitable for applications where this is the primary requirement.

- Not Suitable for Material Protection: Spring washers do not serve the purpose of protecting the material being fastened. They focus on maintaining tension rather than preventing material damage.

Helping Users Make Informed Decisions:

The choice between flat washers and spring washers should be guided by the specific needs of your project. Consider the following trade-offs:

- Load Distribution vs. Tension Maintenance: If load distribution and material protection are your priorities, flat washers are the better choice. However, if you’re dealing with applications where maintaining tension in the fastener assembly is critical, spring washers are the way to go.

- Vibrations and Temperature Fluctuations: In vibration-prone environments or scenarios with significant temperature fluctuations, spring washers offer superior reliability. Flat washers may be more suitable for static applications.

- Versatility vs. Specialization: Flat washers are versatile and can be used in various projects, whereas spring washers are more specialized, finding their niche in industries with specific requirements.

By considering these trade-offs, you can confidently select the right type of washer for your fastening needs, ensuring the safety and reliability of your connections.

Common Mistakes and Best Practices When Using Flat Washers and Spring Washers

While flat washers and spring washers are essential components in the fastening world, using them incorrectly can lead to a host of issues, including connection failure and material damage.

In this section, we’ll highlight some common mistakes people make when using these washers and provide best practices for their proper installation and usage.

Common Mistakes When Using Washers:

- Incorrect Sizing: One of the most frequent mistakes is choosing the wrong washer size. Using a washer that is too small or too large for the fastener can compromise the effectiveness of load distribution and tension maintenance.

- Using the Wrong Type: Mixing up flat washers and spring washers is a common error. Using a spring washer when a flat washer is required, or vice versa can lead to issues like insufficient tension or material damage.

- Overlooking Material Compatibility: Neglecting to consider the compatibility of the washer material with the fastener or the material being fastened can result in corrosion or incompatibility issues over time.

- Over-Tightening: Some individuals tend to over-tighten fasteners, assuming it provide greater security. This can lead to material deformation or even washer failure, especially in the case of flat washers.

Best Practices for Proper Installation and Usage:

- Correct Sizing: Ensure that the washer’s inner diameter matches the fastener’s diameter, and the outer diameter suits the application. Correct sizing guarantees effective load distribution and tension maintenance.

- Type Selection: Carefully select the type of washer based on your specific needs. Use flat washers when even load distribution and material protection are the priority, and employ spring washers for applications with vibration, temperature fluctuations, or self-loosening concerns.

- Material Compatibility: Consider the environment in which the fastener will operate and choose a washer material that is compatible with the fastener and the material being fastened. This helps prevent corrosion and material incompatibility.

- Proper Torque: Avoid over-tightening fasteners. Use a torque wrench to achieve the recommended torque values for your specific application.

- Inspection and Maintenance: Regularly inspect connections that use washers, especially in critical applications. Ensure that washers are still functional and that the fasteners maintain proper tension. Replace worn or damaged washers promptly.

- Industry Standards: Familiarize yourself with industry standards and guidelines for washer usage in your specific field. These standards can provide valuable insights and recommendations for proper washer selection and installation.

By avoiding common mistakes and following best practices, you can maximize the effectiveness of flat washers and spring washers in your fastening applications.

These practices not only help prevent problems but also ensure the longevity and reliability of your connections, whether in construction, machinery, automotive, or any other industry that relies on secure fastening.

Recommended: Top 10 Bolts and Nuts Manufacturers in China

(+86) 188-2253-7569

(+86) 188-2253-7569