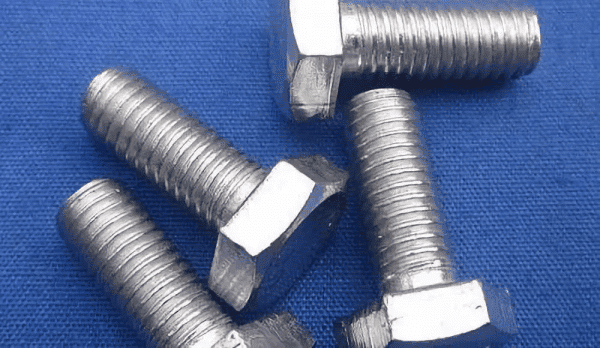

Almost all commercial fasteners are made of carbon steel and alloy steel and are generally corrosion-resistant. Therefore, the coating of the surface treatment must be firmly attached and not shed during installation and dismounting. On the other hand, for threaded fasteners, the coating is required to be thin enough so that the threads can still screw together after plating. Generally, the temperature limit of the coating is lower than that of the fastener material, so it is also necessary to consider the operating temperature requirements of the fastener.

The main purpose of surface treatment is aesthetics and corrosion prevention. Because the main function of fasteners is fastening parts, the surface treatment has a great impact on its fastening performance. Therefore, in the selection of the surface treatment process, the fastener torque and preload consistency should be considered.

A high-level designer should not only consider the structural design and manufacturing process, but also pay attention to the manufacturability of assembly, and even the requirements of environmental protection and economy. Based on the above factors, the following is a brief introduction to some commonly used coatings on fasteners for the reference of fastener practitioners.

Electric Galvanized

Electrogalvanized is the most commonly used coating for commercial fasteners. It’s cheaper, it looks better, and it comes in black or army green. However, its anti-corrosion performance in general, its anti-corrosion performance is the lowest in the zinc plating (coating) layer. General electric galvanizing neutral salt spray test within 72 hours, there is also a special sealing agent, so that the neutral salt spray test for more than 200 hours, but the price is expensive, 5~8 times that of general galvanizing.

Electro galvanizing process is easy to produce hydrogen brittleness, so the bolts above grade 10.9 generally do not use galvanizing treatment. Although the oven can be dehydrogenated after plating, because the passivation film will be destroyed at more than 60℃, dehydrogenation must be carried out before passivation after electroplating. Such as poor operability, and high processing cost. In reality, the general manufacturing plant will not actively dehydrogen, unless specific customer requirements.

Electrogalvanized fasteners torque – preload consistency is poor and unstable, generally not used in important parts of the connection. In order to improve the torque-preload consistency, the method of coating lubricating material after plating can also be used to improve and improve torque-preload consistency.

Phosphating

A basic principle of phosphating is relatively cheap galvanized, with corrosion resistance than galvanized poor. After phosphating should be coated with oil, the level of its corrosion resistance and the performance of the oil have a great relationship. For example, after phosphating coated general antirust oil, the neutral salt spray test is only 10~20 hours. Coated with high-grade antirust oil, it can reach 72~96 hours. But its price is 2~3 times that of the general phosphating coating.

Fasteners commonly used two kinds of phosphating, zinc phosphating, and manganese phosphating. Zinc phosphating lubrication performance is better than manganese phosphating, and manganese phosphating corrosion resistance, and wear resistance are better than zinc. It can be used at temperatures from 225 to 400 degrees Fahrenheit (107 to 204 degrees Celsius). Especially the connection of some important parts. For example, connecting rod bolts, nuts, cylinder heads, main bearings, flywheel bolts, wheel bolts, nuts, etc.

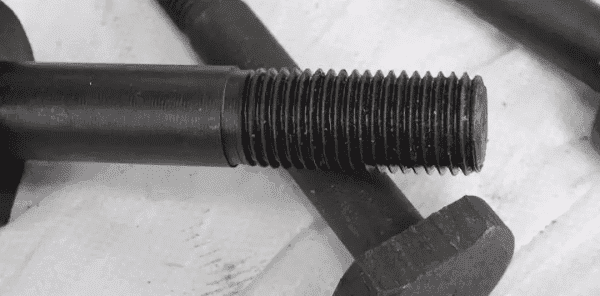

High-strength bolts use phosphating, but also to avoid the problem of hydrogen brittleness, so in the industrial field of 10.9 grade above bolts generally use phosphating surface treatment.

Oxidation (blackening)

Blackening and oiling is a popular coating for industrial fasteners because it is the cheapest and looks good before the oil runs out. Since blackening has little protection against rust, it rusts quickly without oil. Even in the presence of oil, the neutral salt spray test can only reach 3 ~ 5 hours.

Cadmium plating

The corrosion resistance of cadmium coating is very good, especially in the Marine atmosphere, the corrosion resistance is better than other surface treatments. The waste liquid treatment cost in the process of electroplating cadmium is large and the cost is high. The price is about 15 ~ 20 times that of electroplating cadmium. Therefore, it is not used in the general industry, only for some specific environments. For example, fasteners are used for oil drilling platforms and HNA aircraft.

Chromium plating

Nickel plating

Nickel plating is the process of plating a layer of nickel on a metal or certain nonmetals by electrolysis or chemistry. Nickel plating is divided into electroplating nickel and electroless nickel plating.

It is mainly used as a preservative and has good electrical conductivity. Such as the vehicle battery lead terminal, etc.

Hot dip zinc is a thermal diffusion coating of zinc heated to a liquid. Its coating thickness is 15~100μm, and not easy to control, but good corrosion resistance is mostly used in engineering. Hot-dip zinc processing in the process of serious pollution, such as zinc waste and zinc steam.

Due to the thick coating, it is difficult to screw the internal and external threads in the fasteners. Due to the temperature of hot-dip zinc processing, (340-500C), it can not be used for fasteners of class 10.9 and above.

Zinc impregnation

Zincing is a zinc powder solid metallurgical thermal diffusion coating. Its uniformity is good, the thread, and the blind hole can get a uniform layer. The coating thickness is 10 ~ 110μm, and the error can be controlled at 10%. Its binding strength and anti-corrosion performance with the substrate in zinc coating (electro-galvanized, hot-dip zinc, Dacromet ) is the best. The processing process is pollution-free and the most environmentally friendly.

Dacromet

DACROMET is a translation and abbreviation of DACROMET, DACROMET rust. Zn-cr coating is a new anti-corrosive coating with zinc powder, aluminum powder, chromic acid, and deionized water as the main components.

There is no hydrogen embrittlement problem, and the torque-preload consistency is good. In fact, it is most suitable for high-strength fasteners with high anti-corrosion requirements, regardless of valence chromium and environmental protection issues.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569