Bolts are fundamental fasteners used to secure and hold objects. They come in various materials, shapes, and sizes, but regarding strength and durability, steel bolts are preferred.

As steel bolts have different grades, here, we will explore everything you need to know about steel bolts, from what grades of steel bolts exist to how they are used in everyday applications.

By the end of this article, you will have a thorough understanding of the different steel bolt grades and how to choose the proper Bolts Grades for your project. So let’s start becoming an expert on Steel Bolts Grades!

Introduction Of Steel Bolts

A bolt serves as a connector for multiple components, ensuring that they remain securely fastened.

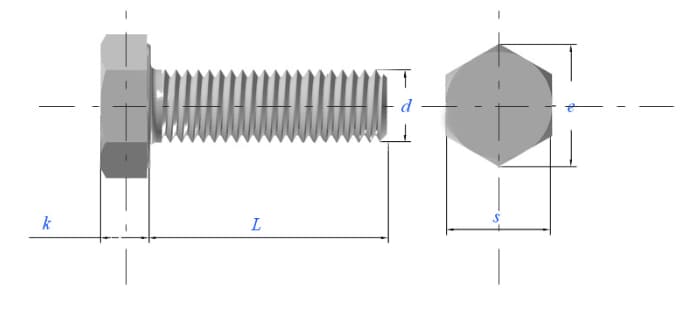

It consists of a head and a threaded rod, which is designed to be inserted into pre-drilled holes or nuts to hold objects or materials.

Steel bolts are usually made from a variety of grades of steel, ranging from low-carbon steel to high-strength alloy steel.

They are used in a wide range of industries, from automotive to aerospace, and have numerous other applications.

They can attach parts to machines, join materials, or fasten objects to a wall or floor.

Advantages Of Using Steel Bolts

- Steel bolts are an excellent choice for many applications, thanks to their strength and durability.

- They are less prone to corrosion than other bolts, which means they last longer and won’t weaken over time.

- Steel bolts are also the most reliable choice for industrial environments that require fasteners that can withstand extreme temperatures and pressures.

- Also, they are strong enough to withstand a high level of wear and tear. This makes them suitable for use in construction projects or any application where the bolts are required to handle a lot of force.

- Steel bolts offer an ideal solution for all kinds of projects, as they are affordable and available in a variety of sizes to accommodate any budget.

These features make steel bolts an excellent choice for any situation where strength and durability are of high importance.

The Manufacturing Process Of Steel Bolts

Steel bolts must be made to exact specifications to ensure they meet the requirements.

Manufacturing steel bolts is an intricate process, demanding immense precision and attention. It involves several steps:

- To start, the unrefined material is heated and transformed into a form called a die, subsequently being trimmed to the required size and shape of the bolt.

- When the bolt has been forged, it is put through a tempering process to strengthen it even more and ensure it can withstand harsh conditions.

- When the bolt is heat-treated, it is then ready for the next step in the manufacturing process. It involves threading the bolt, which is done by using a machine designed specifically for this purpose. The thread is carefully sliced onto the bolt so it can be securely fastened onto the desired object.

- After the threads are cut, the bolt is ready for the final step of the manufacturing process, which is to finish the surface. This is done by applying a coating of paint or lubricant to protect the steel from corrosion and to ensure that it looks attractive.

Steel Bolts Grades

Steel bolts come in various grades, determined by the type of steel used in the manufacturing process.

Understanding Steel Bolts Grades Markings

Steel bolt grades are usually designated by a number, which indicates the level of strength and durability of the bolt.

The number indicates the steel grade used in the manufacturing process. The higher the number, the sturdier and more durable the bolt.

The most common steel bolts grades markings are Grade 2, Grade 5, and Grade 8. These grades are marked on the top of the bolt.

For example, Grade 2 steel bolts are usually marked with a 2 on the head.

Steel Bolts Grades Specifications

The specifications for each steel bolt grade are determined by the ASTM or SAE standards.

The specifications for each grade of steel bolt include:

- The type of steel used.

- The strength of the steel.

- The extra hardness of the steel.

- The excellent corrosion resistance of the steel.

The Different Classes Of Steel Bolts Grades

Steel bolts are manufactured to meet a wide range of specifications, and each grade of steel bolt has different characteristics and uses.

There are two classes of steel bolt grades ASTM and SAE.

Steel Bolts – ASTM Grades

- A307 Steel bolts are typically hot-dipped galvanized and have a nominal tensile strength of 50 kilo-pound per square inch or 315MPa. Piping systems and water tank applications frequently make use of them.

- ASTM A325 Steel bolts are manufactured from carbon steel and are the most common type of bolt found in industrial applications such as construction equipment and automobiles.

- A325 type 1 Steel bolts are considered low-carbon steel, most commonly available in the United States, and have a tensile strength of 80 kilo-pound per square inch or 480MPa.

- Medium carbon steel A325 type 2 Steel bolts are designed for high tensile requirements and are stronger than type 1 bolts with a typical tensile strength of 90 kilo-pound per square inch or 600MPa.

- A325 type 3 Steel bolts have a tensile strength of 120 kilo-pound per square inch or 825MPa and are more commonly used in Canada than the US due to their high strength requirements. Made from sturdy, high-carbon steel for exceptional durability, they are designed to last long.

- A354 grade BC Steel bolts have a tensile strength of 130 kilo-pound per square inch or 880MPa and are commonly known as the strongest bolt for concrete applications because it is not susceptible to corrosion at higher strength levels. Their tensile strength makes them ideal for general use and structural bolting applications.

- A354 grade BD Steel bolts offer increased corrosion resistance compared to grade BC bolts but do not provide increased resistance to corrosion like type 2 bolts with a typical tensile strength of 150 kilo-pound per square inch or 1010MPa. Their tensile strength makes them perfect for heavy structural bolting applications requiring higher strength and durability.

- A449 Steel bolts have a tensile strength of 140 kilo-pound per square inch, perfect for heavily loaded or high-stress connections requiring high strength or durability.

- ASTM A490 type 1 Steel bolts can be used in bolted joints subject to moderate loads or cyclical stresses. They can be used in bolted joints subject to severe loading or ultimate strengths.

Learn more: Super Detailed–Metric Thread Sizes Chart

Steel Bolts – SAE Grades

Steel bolts are available in a variety of SAE grades, ranging from 1 to 8.2. The steel bolt grades refer to the level of carbon in the bolts.

- SAE Grade 1: 0.03% and 0.06%.

- SAE Grade 2: 0.07% and 0.10%.

- SAE Grade 5: 0.11% and 0.14%.

- And so on, up to SAE Grade 8, which has a maximum of 0.25%.

Bolts made from SAE Grade 8 can be used in higher-strength applications, such as those that must support heavy loads or withstand significant pressure due to weight or tension.

- Grade 1 bolts are considered the lowest grade of steel bolts and are suitable for low-load applications.

- Grade 2 bolts are stronger than grade 1 and are typically used for light-duty applications or where a high degree of corrosion resistance is required.

- Grade 5 bolts are made from medium carbon alloy steel, offering higher strength and greater fatigue resistance than grade 2.

- Grade 5.2 bolts are similar to grade 5 but with special heat treatment for increased strength.

- Grade 7 bolts are made from heat-treated alloy steel and are typically used in heavy-duty applications.

- Grade 8 bolts are the strongest, made from heat-treated alloy steel and designed for extreme strength and fatigue resistance.

- Finally, grade 8.2 bolts are similar to grade 8 but with a special coating to further increase strength and protect against corrosion.

By understanding the different SAE grades of steel bolts, you can definitely choose the right type for your application.

Strength And Durability Of Steel Bolts Grades

The strength of steel bolts is determined by the grade of steel used in the manufacturing process.

Grade 2 steel bolts are the least strong, Grade 5 steel bolts are more durable, Grade 8 steel bolts are even more durable, and those above grade 8 are the strongest and most durable.

Corrosion Resistance Of Steel Bolts Grades

The corrosion resistance of steel bolts is determined by the type of steel used in the manufacturing process.

Grade 2 steel bolts are the least corrosion resistant, Grade 5 steel bolts are more corrosion resistant, Grade 8 steel bolts are even more corrosion resistant, and Grade 9 steel bolts are the most corrosion resistant.

Cost Considerations Of Steel Bolts Grades

The price of steel bolts is determined by the type or grade of metal used in their production.

Grade 2 steel bolts are the least expensive, Grade 5 steel bolts are more expensive, and Grade 8 steel bolts are even more costly.

It is essential to consider the cost of the bolt when choosing the suitable grade for your project.

Choosing The Best Steel Bolts Grade Supplier

- When choosing a steel bolts grade supplier, it is vital to consider the supplier’s reputation, product quality, and pricing.

- It is necessary to ensure the supplier you choose is certified to provide the grade of steel bolts you need.

- A supplier should be able to provide certification that the steel bolts they provide meet the ASTM or SAE standards.

- Then, it is also essential to ensure the supplier can provide the suited grade of steel bolts for your project and ultimate customer support.

How To Choose the Correct Steel Bolts Grades?

Application

When selecting the proper grade of steel bolts for your project, it is vital to consider their application and the type of material they would work in.

Based on application, you should consider a grade of steel that can withstand the desired level of force.

There are three main types of applications:

- Structural fastening includes joints in buildings and infrastructure that must resist high loads.

- Non-structural fastening includes lower-strength joints not subject to high loads.

- Seismic jointing involves specialized fasteners, especially for earthquake-resistant construction.

Environment

The other thing to consider is the environment in which the bolt will be used, as it can impact its corrosion resistance and strength properties.

For example, if the bolt is used outdoors in a saltwater environment, it should be made from stainless steel or another material that resists corrosion.

Cost

Then, consider the cost of the bolt when choosing the suited grade according to your needs and requirements.

Well-Known Supplier

Finally, be sure that the supplier offers high-level customer and technical support. It is also crucial to ensure the supplier you choose is certified to provide the grade of steel bolts you need.

Other Pro Tips

- Familiarize yourself with the various grades of steel bolts.

- Choose the appropriate strength and hardness for your needs.

- Select a grade of steel bolt that meets the requirements for your project.

- Ensure the bolt you chose is ideal for the substances it will encounter.

Ensure your project’s success by heeding these recommendations for selecting the ideal steel bolt grade.

Conclusion

Steel bolts are an essential part of any application that requires secure fastening and are available in different grades for different applications.

Understanding the steel bolt grades, you can choose suitable fasteners for your application.

Through this guide, we aim to enlighten our readers on the varied grades of steel bolts. There are so many factors to consider when purchasing bolts, and sometimes it can be overwhelming.

If this is the case, please don’t hesitate to reach one of our professional but friendly staff members, who are more than happy to answer any questions or help in any way they can!

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569