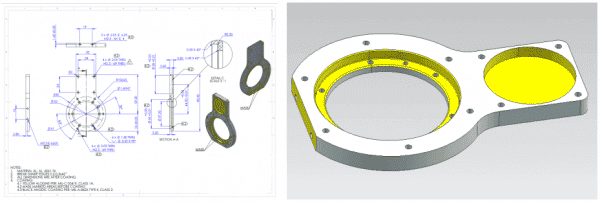

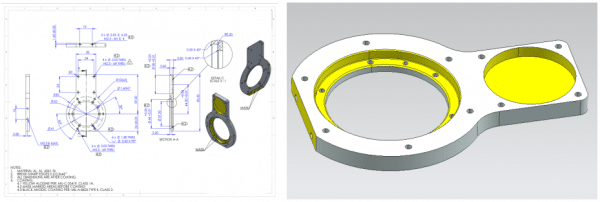

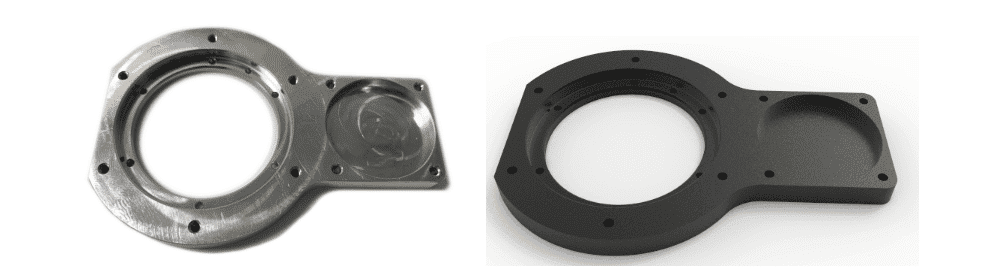

This aluminum flange optical accessory is a custom milling aluminum part made and processed with aluminum 6061 T6 as the base material. This aluminum flange is not very difficult to process, and many custom milling suppliers can easily do it. During the processing of these aluminum flange optical accessories, the custom milling supplier will spend more energy on the details.

Or ask the custom milling supplier to at least let an experienced machining engineer perform manual machining, or ask a programmer with rich experience in CNC milling to set a more reasonable machining program for automatic machining. The former has high flexibility in machining.

Product parameters

Product Name: Flange

Product Purpose: It’s Used in Optical Accessories

6061-T6 Material: Aluminum 6061-T6

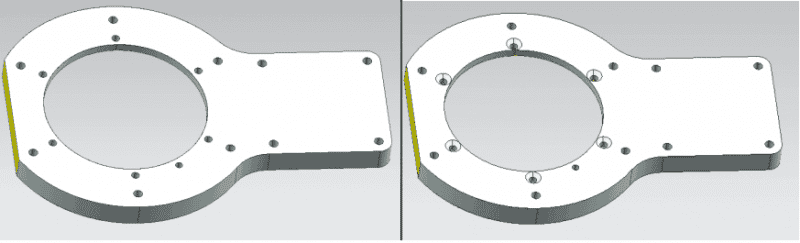

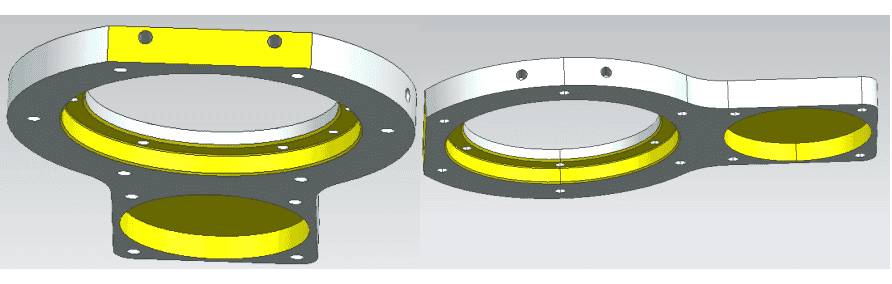

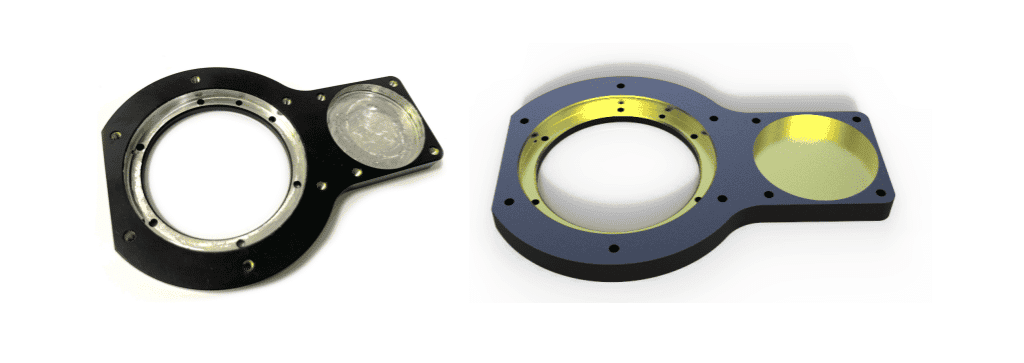

Surface Treatment: Black Anodized and Yellow Conductive Oxidation

Brief Introduction of Aluminum 6061-T6

With high strength, and high hardness (up to HV90 degrees or more) aluminum has a good processing effect and oxidation effect. It hasn’t trachoma stomata, flatness is better. It can improve processing efficiency and reduce material costs. Aluminum 6061-T6 is the best choice for a low-price and high-quality material. 6061-T6 series for aluminum, magnesium, and silicon alloy that is a heat treatment type of corrosion resistance alloy. The strength and corrosion resistance is better and the uniformity is better. The density of 6061 aluminum alloy is 0.0000028.

Our aluminum flange optical accessories also inherit the strength and milk corrosivity of aluminum 6061-T6. Considering that aluminum flange optical accessories will inevitably encounter chemical substances in the laboratory, most custom milling suppliers also have specially carried out a deeper layer of protection and surface treatment for them, and our Yijin Hardware is no exception. We will mention our surface treatment process for these aluminum flange optical accessories below.

Application

The main alloying elements in the 6061 series aluminum alloy are magnesium and silicon, which have medium strength, good corrosion resistance, weldability, and a good anodized effect. Widely used in various industrial structures requiring certain strength (85-110 degrees) and high corrosion resistance. Such as manufacturing trucks, tower construction, ships, trams, railway vehicles, furniture machinery parts, precision processing, molds, and so on.

At the same time, some sophisticated and experienced custom milling suppliers have their purchasing channels, and the price will be slightly cheaper than the market, and then they will be more favorable when they are used to cultivating their own processing technology or customizing CNC machining products for old customers. This is the case with Yijin Hardware. We are the custom milling supplier with the highest customer stickiness. There are countless customers who have cooperated with us for more than 5 years.

Chemical Component

Cu:0.15-0.4

Si:0.4-0.8

Fe:0.7-,0.13

Mn0.15-0.50

Mg:0.8-1.2

Zn:0.25-0.50

Cr:0.04-0.35

Ti:0.15-0.63

They are four-digit aluminum alloys with magnesium and silicon as the main alloying elements and the Mg2Si phase as the strengthening phase.

Alloy States

T6 The condition of artificial aging after solution heat treatment. It is suitable for products that are no longer cold-processed after solid solution heat treatment (can be straightened and leveled, but does not affect the limit of mechanical properties).

Processing Technic

The Tool of Quantity: 9tools

Tool Type: ∅16 coarse skin cutters, ∅10 butt mills, ∅2.05 drill bit, ∅1.5 drill bit, ∅1.6 reamers, M2.5 screw tap, ∅5 rose reamer

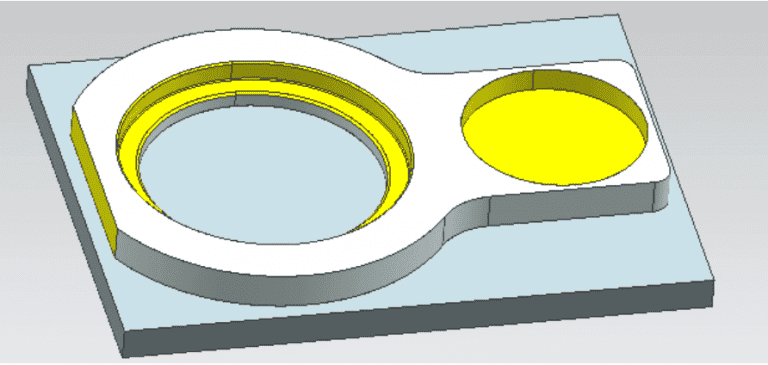

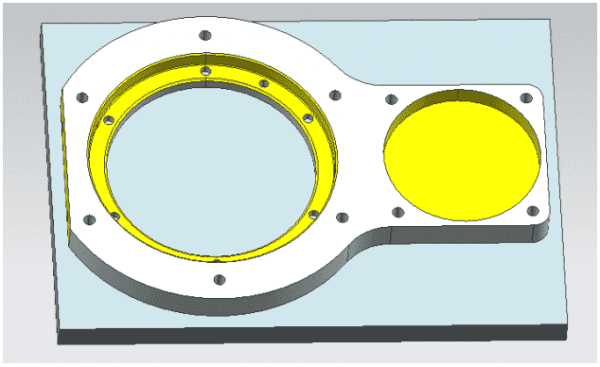

The parts have special surface treatment requirements that need to do the two-color surface treatment. They are black anodized and yellow conductive oxidation, as shown in the 3D drawing above. In order to meet the requirements of the surface of this part, we adopt the following processing methods:

①Rough machining the shape of the parts with ∅16 coarse skin cutters,∅10 butt mill finish machining parts shape, and reserved finishing allowance for the yellow area marked on the drawing.

②Use ∅1.5 drill bit and ∅1.6 reamer machining ∅1.60H7, then use ∅2.05 drill bit and M2.5 screw tap machining size of 4x∅2.5THTU-M2.5-H6THRU, 6x∅2.5THTU-M2.5-H6THRU, finally use ∅1.8 drill bit machining 6×1.8THRU.

③Use ∅16 coarse skin cutters and ∅10 butt mill machining height dimensions 5.6 and use ∅5 rose reamer finish machining ∅3.60×90°.

④Use ∅2.05 drill bit and M2.5 screw tap to machining 2x∅2.05↓6.25-M2.5-6H,then use ∅2.05 drill bit and M2.5 screw tap to machining M2.5↓6(x2).

⑤Black anodized.

⑥Custom-made clamp and then use ∅10 butt mill to machine reserved areas of margin, finally make yellow conductive oxidation.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569