Woodworking has been a timeless craft, combining artistry and functionality to create exquisite pieces.

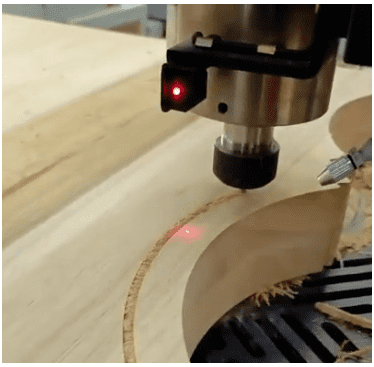

With advancements in technology, CNC (Computer Numerical Control) machining has revolutionized the woodworking industry, enabling precise and intricate designs to be brought to life.

CNC machines can carve, cut, and shape wood with remarkable accuracy and efficiency.

There are a number of options available to you if you’re looking for CNC machining services for wood.

In this article, we’ll delve into the top locations to find such services, each offering unique benefits to cater to your specific needs.

1. Local Machine Shops

Local machine shops are a fantastic option for individuals seeking CNC machining services for wood.

These shops are usually equipped with various CNC machines, including routers and mills, designed to work with wood materials.

Here are some reasons why local machine shops are a great choice:

-

Personal Interaction:

One significant advantage of visiting a local machine shop is the opportunity for personal interaction.

Unlike online services, you can directly communicate with the machinists and discuss your project requirements face-to-face.

This personal touch allows for a better understanding of your vision, leading to a more satisfactory end product.

-

View Examples of Previous Projects:

By visiting a local machine shop, you can view tangible examples of their previous woodworking projects.

This gives you a glimpse of their capabilities and craftsmanship, helping you make an informed decision about whether their style aligns with your project goals.

-

Quick Turnaround for Local Customers:

Local machine shops can offer quicker turnaround times for customers in the vicinity. Since there’s no need for shipping, you can potentially receive your finished woodwork sooner.

This quick service can be particularly beneficial for urgent or time-sensitive projects.

[row]

[col span=”1″ span__sm=”12″]

[/col]

[col span=”10″ span__sm=”12″]

[ux_video url=”https://youtu.be/OIqwapJGmDk”]

[/col]

[col span=”1″ span__sm=”12″]

[/col]

[/row]

2. Woodworking Trade Shows and Events

Attending woodworking trade shows and events can be an excellent way to discover CNC machining services for wood.

These gatherings often feature various exhibitors, including CNC machine shops specializing in woodworking.

Here’s why you should explore trade shows and events:

-

Observe a variety of CNC machines in action:

One of the most exciting aspects of woodworking trade shows is the chance to witness an array of CNC (Computer Numerical Control) machines in action.

These machines have transformed the woodworking landscape, offering precise and efficient results that were once unthinkable with traditional tools.

At trade shows, exhibitors showcase various CNC machines, such as CNC routers, CNC lathes, and CNC mills, each tailored to specific woodworking tasks.

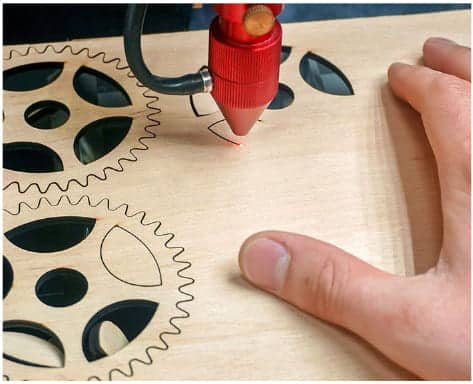

Visitors can observe how these machines handle intricate designs, carve out detailed patterns, and effortlessly process different types of wood.

Observing CNC machines in action offers priceless insights into their prospective uses and capabilities.

Visitors can witness the speed, accuracy, and versatility of these machines, leading to a better understanding of how to incorporate them into their own woodworking projects.

Whether you are a seasoned woodworker or just starting, observing CNC machines at trade shows can spark inspiration and creativity, encouraging attendees to explore new techniques and designs.

-

Meet and talk directly to providers:

Trade shows bring together a diverse array of woodworking equipment manufacturers, suppliers, and experts, offering attendees the unique opportunity to engage in direct conversations with these industry professionals.

This direct interaction facilitates a deeper understanding of the products and services offered by different providers, as well as the chance to compare and contrast offerings from various companies.

Meeting the providers face-to-face enables attendees to ask specific questions, seek advice, and gain insights into the best solutions that suit their individual woodworking needs.

It is an excellent chance to inquire about technical specifications, maintenance requirements, and even the possibility of customizing machinery to suit specific projects.

Additionally, building relationships with providers can lead to long-term benefits, such as being informed about future product releases, special offers, and technical support.

These connections can be instrumental in the growth of a woodworking business or hobby.

-

Direct Interaction with Experts:

Trade shows and events bring together experts in the woodworking industry. You can directly interact with CNC machinists, inquire about their processes, and gauge their proficiency in handling wood projects.

-

Live Demonstrations:

Some trade show booths might showcase live CNC machining demonstrations, giving you a real-time understanding of the machine’s capabilities and the level of precision, they can achieve with wood.

3. Specialized CNC Woodworking Service Providers

In the world of woodworking, precision, efficiency, and innovation are key to success. The advent of Computer Numerical Control (CNC) technology has significantly transformed the woodworking industry, enabling intricate designs, complex cuts, and streamlined production processes.

While many woodworking businesses invest in their own CNC machines, there has been a growing trend toward outsourcing CNC services to specialized providers.

Companies like Yijin Solution or 3D Hubs have emerged as pioneers in this domain, offering unparalleled CNC woodworking services that cater to the diverse needs of businesses and individuals alike.

-

Harnessing the Power of CNC Technology:

CNC technology has revolutionized woodworking by replacing traditional manual processes with computer-controlled precision.

These specialized service providers leverage state-of-the-art CNC machines that can execute precise cuts, carvings, and engravings with incredible accuracy.

Whether it’s crafting intricate furniture pieces, creating custom cabinetry, or manufacturing complex wooden components, CNC woodworking service providers have the equipment and expertise to handle a wide range of projects.

-

Fast Quote System:

Time is of the essence in the fast-paced world of woodworking. Specialized CNC service providers understand this need for promptness and have implemented fast and efficient quote systems.

When customers submit their design files or project specifications, these providers quickly analyze the requirements and generate detailed quotes in a short period.

The level of transparency builds trust between the service provider and the client, ensuring a smooth and hassle-free collaboration.

-

Handling Large Orders with Ease:

For woodworking businesses, taking on large orders can be both exciting and daunting. Scaling up production requires substantial resources, and specialized CNC service providers are well-equipped to handle such challenges.

With a fleet of advanced CNC machines and a team of skilled operators, they can efficiently manage large-scale orders without compromising on quality or turnaround time.

Outsourcing large orders to specialized CNC woodworking service providers can be a strategic decision for businesses looking to expand their capabilities and meet the demands of a growing customer base.

-

Expertise and Guidance:

Beyond their CNC capabilities, these service providers often boast a team of experienced woodworking professionals who can offer valuable guidance and technical expertise.

From material selection to design optimization, these experts can assist clients in making the right decisions throughout the project’s lifecycle.

Their insights can lead to cost savings, improved product quality, and faster production times, elevating the overall woodworking experience.

-

Flexibility and Customization:

Every woodworking project is unique, and specialized CNC service providers understand the importance of flexibility and customization.

They can work with a wide range of materials, including hardwoods, softwoods, plywood, and even exotic woods.

Whether it’s a one-of-a-kind art piece or a mass-produced furniture line, these providers can tailor their services to suit individual requirements.

Conclusion:

Specialized CNC woodworking service providers have undoubtedly made a profound impact on the woodworking industry.

Their ability to harness the power of CNC technology, coupled with fast quote systems and the capability to handle large orders, has revolutionized the way woodworking projects are approached and executed.

For businesses and individuals looking to bring their woodworking visions to life with precision and efficiency, collaborating with these specialized providers offers a gateway to unparalleled craftsmanship and success.

As CNC technology continues to advance, we can only expect these specialized services to drive further innovation, pushing the boundaries of what’s possible in the world of woodworking.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569