CNC machining has transformed the industrial sector. Manufacturers are producing more efficient and accurate components.

CNC machinists are capable of creating parts with exact accuracy by using computer-controlled cutting tools and machines. It was impossible to achieve by traditional methods.

This level of accuracy also allows for smaller production times, causing lower costs for manufacturers and buyers.

CNC machining has been around for decades. Recently, the CNC machining industry facing a recession. Please read on to find out.

What is CNC Machining?

Computer Numerical Control or CNC machining is a manufacturing procedure in which pre-programmed CAM/CAD software commands the drive of factory tools and machinery.

The procedure can control complex machinery, from lathes and grinders to mills plus CNC routers.

With CNC machining, 3-dimensional cutting jobs can be achieved in a single set of commands.

With a CNC machine, programs are entered via punch cards. The programs for CNC machines are provided to computers over small keyboards.

CNC programming is kept in a PC’s memory. The code itself is written plus edited by programmers.

Thus, CNC systems offer far more extensive computational capacity.

Greatest of all, CNC systems are static since newer commands could be added to pre-existing programs over revised code.

What Role Does It Play in Modern Manufacturing?

The precision of the CNC machine certifies consistent product quality. The procedure is more accurate than manual machining and could be repeated in the same way repeatedly.

Increased Efficiency and Increased Production Speed

Computers are used to control the machine; the procedure is automated, increasing the quality and speed of manufacturing.

CNC machines do not tire out or need breaks. It makes the process more efficient than manual machining.

Safer

Using CNC machines is much safer than using manually operated machines. They work behind a closed, transparent safety door.

More Cost-Effective

Traditional machining needs one operator per machine. This kind of machining needs fewer machine operators as one expert operator could run several machines simultaneously.

More Precise

Since the CNC is so precise, it decreases errors in the manufacturing procedure and removes unnecessary waste.

Can CNC Machining be replaced by Other Processes?

Absolutely Not. 3D printing and Die casting have some benefits but cannot replace CNC machining in several areas.

Regarding dimension tolerance, the CNC machining component is much better than the die-casting object.

There is an extra procedure for the Metal 3d printing and CNC machining process, for example eliminating the burr.

What Caused The Burr Formed In CNC Machining?

Other machining types

3D Printing

3D printing is an additive procedure where an object is made or manufactured by adding one layer or piece over the other.

In conflict with this, CNC machining is a subtractive technique. It means smaller pieces are eliminated from the larger piece to form a given object.

CNC machining is not likely to get replaced by 3D printing or any other method, at least not soon.

Sheet Metal

Sheet metal fabrication needs a massive setup, numerous machinery, and excellent training for the workers.

CNC, instead, is just one piece of kit that is seamless to use and can be operated for longer hours without increasing the costs exponentially.

CNC machines are very accurate, producing parts with a higher-quality finish.

Metal Stamping

Metal stamping is a manufacturing procedure that converts flat sheet metal into precise shapes.

It is a complex process that can include several metal-forming methods — punching, blanking, bending, and piercing, to name a few.

CNC is extremely slow, but it’s also highly accurate. So CNC would be the way to go if you need absolute accuracy.

Metal Engraving

CNC machining and Metal engraving are subtractive manufacturing technologies.

They eliminate material to make grooves in desired shapes and patterns. Metal engravings are typically faster and less costly than CNC machining.

But they cannot produce deep cuts or complex shapes like CNC machining can. Instead, CNC machining needs more setup time and costs more money.

But it allows for greater complexity and design flexibility while working with metals.

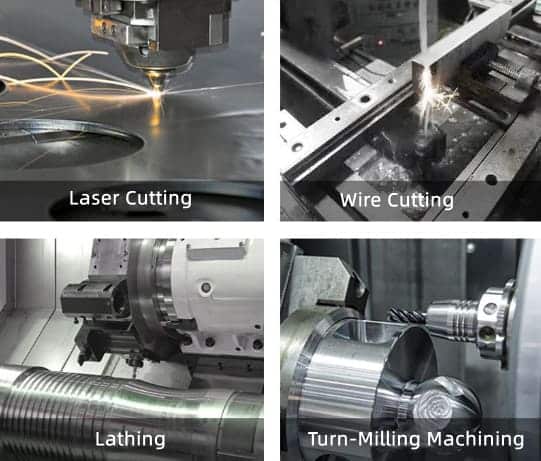

Laser Cutting

The difference between the laser cutting and CNC machining processes comes from how the cutting essentially occurs.

Instead of a cutting tool, a laser uses heat to cut or engrave the product.

CNC cutting carves out the design using a tool you might do by hand, which is more effective and efficient.

Laser cutting relies on a high-energy laser that burns over the material.

CNC machining is more accurate than manual machining and can be repeated similarly. They are great for increasing efficiency and production speed.

Compared to laser cutting, CNC machines are bigger and beneficial for large-scale installations and projects.

Hardwoods, plus dense materials, are also more effective at cutting and shaping. And can cut some materials that are dangerous to fire a laser at.

Plasma Cutting

CNC machine has a tighter tolerance than plasma cutting machine. It is perfect for precise cuts or parts that have complex notching.

A Comprehensive Guide To Plasma Cutting

The CNC machine is typically more expensive to operate but offers a level of detail that the plasma cutter does not.

Die Casting

Die casting contains melting metal plus injecting it into a steel mold. The metal is then cooled down thus it solidifies in the form of the part.

Computer Numerical Control machining or CNC machining automates the procedure by using a robot to mold the part from the metal.

Both of these procedures are frequently used to manufacture metal components and fittings for items that we use every day – for example, computer parts and cars.

CNC machining is also a repeatable, precise process that produces much tighter tolerances than casting.

What Are the Most Common Industries that Use CNC Machining?

Many industries use CNC machines to generate high volume precision turned parts and other parts.

Let us take a look at several of the most common applications these parts are required for:

Electronics

There is a trend of miniaturization within the consumer electronics industry. Components are constantly becoming smaller yet more powerful than before.

The parts need to be compacted and lightweight as well. Small Batch CNC machining is flawless for handling the specialized materials that are required for this.

Examples of products formed for electronics by CNC machines are:

- Electrical Insulation

- Heat sinks

- Housings for amplifiers

- Shielding against radio frequency interference

Medical

The medical field uses customized products that fit the requirements of patients. Since most devices used in medical practices are disposable, these businesses require both high volume and accuracy.

There are many kinds of CNC machines that work fine for generating parts in this industry. Products made for medical businesses using CNC machines contain:

- Orthotic devices

- Research equipment

- Various types of implants

- MRI machines

Aerospace

The aerospace industry has a vast requirement for repeatability and high precision. To ensure the safety and compliance of critical parts, tolerances of just ±0.0001 are essential.

CNC machines are the flawless choice for this, as they are very precise.

CNC machining services are great for making everything from complex bearing housings to high-tolerance spacers.

Here are some other aerospace parts made with CNC machines:

- Airfoils

- Antennae

- Bushings

- Parts for landing gear

Oil & Gas

Drilling rigs and refineries use big machines made with machined parts to confirm they fit perfectly together.

If the fit is not precise, cylinders might not fill, pistons won’t generate the correct pressure, and valves might leak.

Hence, petrochemical companies use parts that have been CNC machined to confirm they fit precisely as required.

The oil and gas industry uses parts generated by CNC machines for refineries, rigs, and pipelines. Some examples are these components are:

- Rods

- Drill bits

- Pistons

- Valves

Marine

The marine industry is another example of a business that depends heavily on parts produced by CNC machining services.

Just like airplanes, watercraft depend on highly-precise parts to keep them running and afloat.

Not to mention all of the marine equipment that goes along with watercraft, for example, communication equipment, underwater sensors, and more.

Hence, CNC companies generate many parts for boats, including:

- Components for the engine

- Propellers

- Insulating cases

- Prototype molds

Military and Defence Industry

Components manufactured for the defense sector have to be robust enough to cope with the severest of environments.

The military also required to be able to keep up with technological advancements to offer the best level of protection.

Regular updates are essential, which can easily be handled by CNC manufacturing.

Common uses of CNC manufacturing in the defense industry include:

- Airplane parts

- Electronics

- Communications components

- Transportation components

The Future of CNC Machining

Progresses in CNC machining continue to make the impossible possible. CNC machining is one of the fastest-growing industries worldwide.

So, where is the industry going? How can CNC machining continue to become faster, more efficient, and more precise? Here is a review of where the industry is going.

Synchronizing Multiple CNC Machines

Maximum prototypes for production manufacturing are achieved with stand-alone machines.

The future of CNC machining is looking towards synchronizing several machines, which massively raises the efficiency and ability of a prototype to the product manufacturing facility.

Increased Accuracy

One thing to look onward to in the future of CNC machining is the use of high-precision machine tools.

These tools have advanced sensors and control systems that allow them to maintain tight tolerances and produce tremendously accurate parts.

The Emerging Use of Robotics

Robotics is another technology that is having a substantial impact on the arena of CNC machining.

In recent years, there has been a rising trend toward using robotics in manufacturing, and CNC machining is no exception.

The Growing Use of Virtual and Augmented Reality

Virtual and augmented reality (VR/AR) are evolving technologies that significantly impact CNC machining.

VR/AR technologies permit users to experience and interact with digital environments and objects similar to the real world.

CNC Machining Employment Projection and Statistics

The CNC machining industry is flourishing right now. As stated by the latest research, between 2019 and 2026, the international CNC machine market is estimated to grow 44 percent, or almost $35 billion.

It is because of a growing demand for automation, accuracy, and efficiency in manufacturing goods.

While people assume that technology might replace hands-on workers, the truth is that the manufacturing field still requires machinists to run CNC equipment.

CNC machinists can anticipate an average wage of $43,170 yearly. In some states, though, the earning prospective is even greater.

Connecticut is amongst the highest-paying states for CNC machinists, as stated by the Bureau of Labor Statistics.

In New England, CNC machinists could anticipate a salary of at least $46,000 yearly.

How Many Jobs Are Available In Metal Fabrication | 2023 Updated

Choose YIJIN Hardware for Your Metal Parts Manufacturing Needs

Please allow me to introduce our company and seek an opportunity to cooperate with your company.

YIJIN Hardware is a leading supplier of high-quality precision machined parts, providing machining services and spare parts for the international marketplace.

We are a CNC custom processing factory, and our company has been specializing in Rapid Prototyping, CNC machining, and Sheet Metal Fabrication products for over 20 years with good quality and very competitive prices.

We offer solutions designed to meet your specific requirements and pride ourselves on quick turnaround time.

If you are interested in our online machining services, contact us at any time, and will be happy to answer all your questions.

Conclusion

CNC machining is a valuable tool for industrial professionals because of its high accuracy, efficiency levels, and capability to quickly and easily produce complex shapes.

By using this technology, businesses can decrease production time and labor costs while growing their overall productivity levels—making it vital for any company looking to stay competitive in today’s market.

CNC machining has been around for decades, yet technological developments keep getting faster, better, and more accurate.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569