Overview of CNC Routing Materials and the Vital Role of Wood Selection:

A. Overview of Materials Used for CNC Routing:

CNC routing is a manufacturing process that involves using computer-controlled machines to remove material from a workpiece to create accurate and complex shapes.

CNC routers have the ability to work with a variety of materials including wood, plastic and metal. Some common materials used for CNC routing include:

- Wood: Various types of wood, such as hardwoods (e.g., oak, maple, walnut) and softwoods (e.g., pine, cedar), are popular choices for CNC routing. Wood is versatile, relatively easy to work with, and offers a natural and aesthetic appeal.

- Plastics: Different types of plastics like acrylic, PVC, polycarbonate, and HDPE can be CNC routed. Plastics are majorly used for signs, displays, and other applications where lightweight and durability are important.

- Metals: CNC routing can be used for softer metals like aluminum, brass, and copper. This is especially useful for creating prototypes or smaller metal parts with precise shapes.

- Foam: CNC routers can cut and shape various types of foam, commonly used in packaging, insulation, and the production of molds for casting.

- Composites: Materials like fiberglass and carbon fiber composites can be CNC routed for applications in aerospace, automotive, and marine industries.

- Solid Surface Materials: Materials like Corian and other solid surface materials are used for creating countertops, sinks, and architectural elements.

- MDF (Medium-Density Fiberboard): MDF is a cost-effective and smooth material often used for indoor furniture, cabinetry, and decorative projects.

B. Importance of Choosing the Right Wood for CNC Projects:

Wood selection plays a vital role in the success and outcome of CNC projects, especially when woodworking is involved.

Below is some common factor that shows how important is to choose the right type of wood.

- Machinability: Different woods have varying densities, hardness, and grain patterns. Some woods are easier to machine and cut, while others may require slower feed rates or more specialized tools. Choosing a wood with good machinability ensures smoother and more efficient CNC routing.

- Finish and Aesthetics: The type of wood used directly impacts the final appearance of the project. Some woods have a distinct grain pattern and color, which can enhance the overall aesthetics of the finished piece. The right wood choice contributes to the desired visual appeal.

- Strength and Durability: For functional projects like furniture or structural components, the strength and durability of the wood are crucial. Some woods are inherently stronger than others and can withstand greater loads or environmental factors.

- Cost Considerations: Different woods come with varying costs, depending on their availability and desirability. It’s essential to balance the project’s requirements with the budget and select a wood that meets both criteria.

- Environmental Factors: If the project will be used outdoors or exposed to moisture, the wood’s resistance to decay and weathering becomes crucial. Certain woods, like teak or cedar, are naturally more resistant to rot and insects, making them suitable choices for outdoor applications.

- Sustainability: Considering the environmental impact of wood is becoming increasingly important. Choosing sustainably sourced wood helps support responsible forestry practices and minimizes the negative impact on the environment.

[row]

[col span=”1″ span__sm=”12″]

[/col]

[col span=”10″ span__sm=”12″]

[ux_video url=”https://youtu.be/OIqwapJGmDk”]

[/col]

[col span=”1″ span__sm=”12″]

[/col]

[/row]

In conclusion, CNC routing allows for the creation of intricate and precise designs in various materials, and wood remains a popular choice due to its versatility and aesthetic appeal.

When selecting wood for CNC projects, considering factors such as machinability, aesthetics, strength, cost, and environmental impact will contribute to the successful execution of the project.

Types of Wood for CNC Woodworking:

A. Hardwood:

1. Definition and characteristics of hardwood:

Hardwood is a type of wood that comes from deciduous trees, which shed their leaves annually. Hardwoods generally have a higher density so, it becomes more durable and resistant to wear.

They often have a complex cellular structure, resulting in a beautiful and varied grain pattern. Some common characteristics of hardwood include:

- Higher density: Hardwoods are generally denser than softwoods, which makes them sturdy and suitable for a wide range of applications.

- Attractive grain patterns: Hardwoods often exhibit striking grain patterns that add to the aesthetic appeal of finished projects.

- Durability: Due to their density, hardwoods are more resistant to wear, making them suitable for functional and decorative applications.

- More Costlier: Hardwoods are Costlier as compared to softwoods due to their slower growth rate and higher demand.

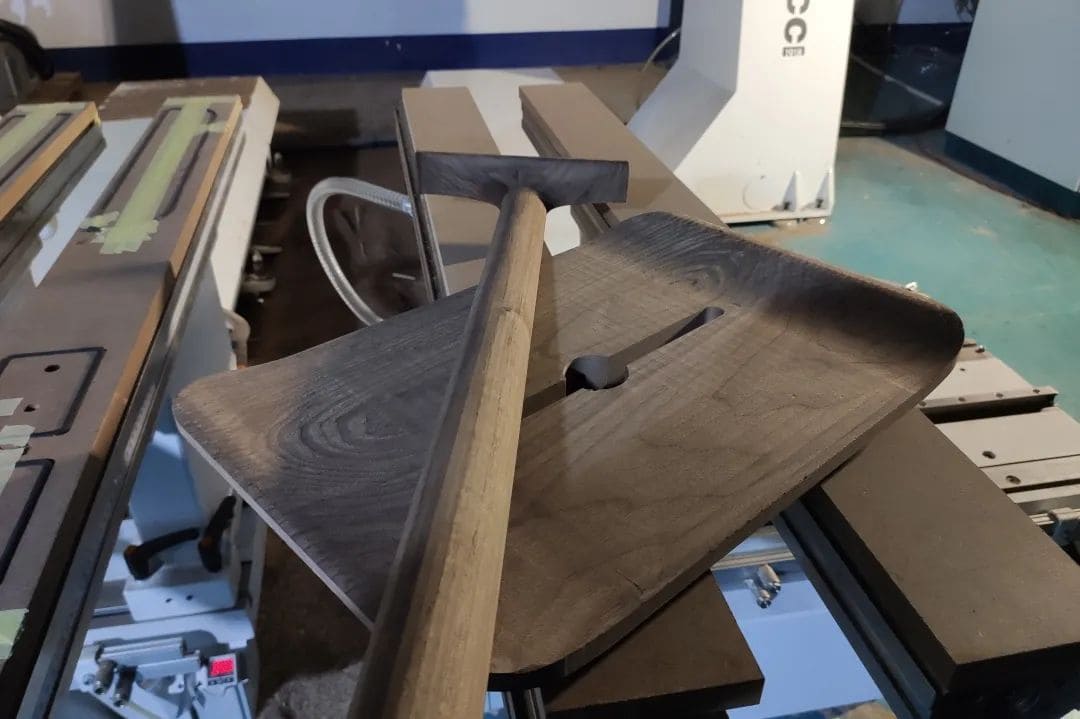

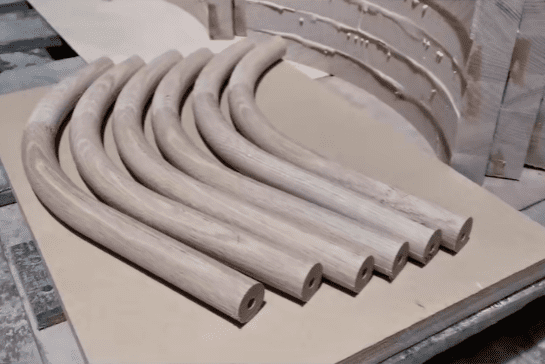

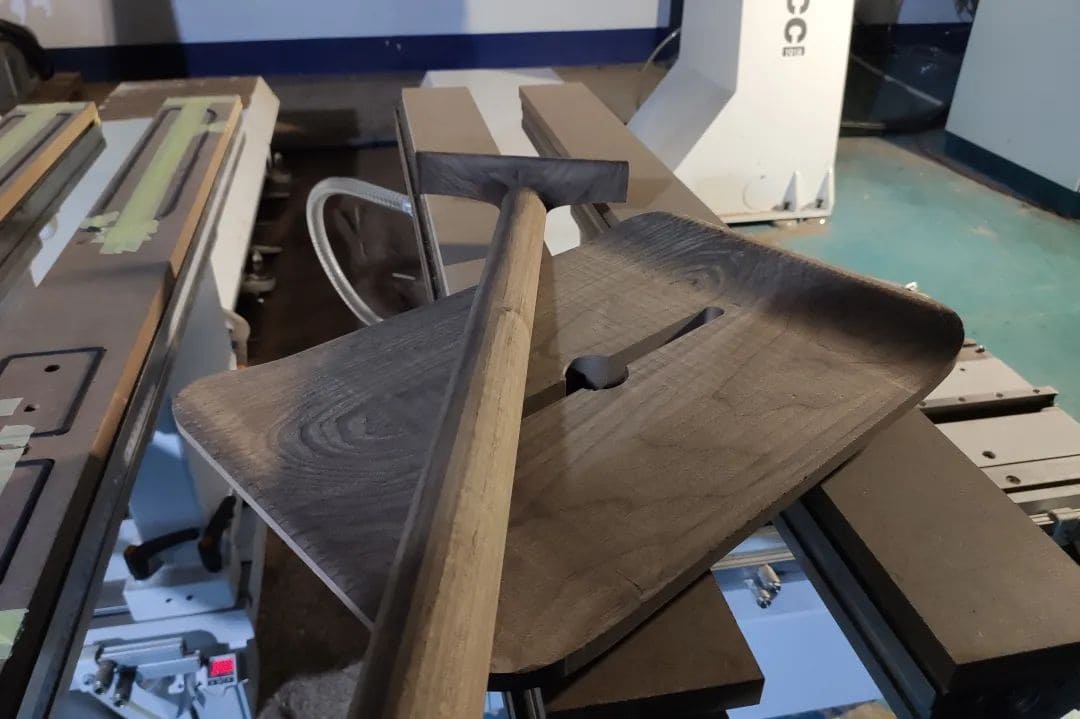

2. Ideal for intricate cuts and small details:

One of the main advantages of using hardwood in CNC woodworking is its ability to hold intricate cuts and small details.

The dense and solid nature of hardwood allows for precise machining without compromising structural integrity.

This makes hardwood an excellent choice for creating fine details, ornate designs, and intricate carvings.

3. Examples of hardwood options for CNC projects:

There are numerous types of hardwoods available, each with its unique characteristics. Here are some popular hardwood options commonly used for CNC woodworking projects:

- Maple: Known for its fine and consistent grain pattern, maple is a versatile hardwood used in furniture, cabinetry, and decorative items.

- Oak: Oak is a durable hardwood with a prominent grain pattern, suitable for both indoor and outdoor projects.

- Walnut: Walnut is a deep-colored hardwood with a beautiful grain pattern that is frequently used in luxurious furnishings and pieces of art.

- Cherry: Cherry wood is reddish-brown in nature. Cherry wood gets darker with time and exposure to light.

- Mahogany: Mahogany is a tropical hardwood with a straight grain and a deep reddish-brown color.

- Ash: Ash wood has a light color and a distinct grain pattern, making it ideal for a variety of CNC woodworking projects.

It’s important to note that the selection of hardwood for CNC projects depends on the specific requirements of the project, including the desired appearance, strength, and budget.

Each type of hardwood has its own unique properties, so it’s essential to consider these characteristics when choosing the right wood for a CNC woodworking project.

B. Softwood:

1. Definition and characteristics of softwood:

The word “softwood” is used to characterize wood from coniferous trees. Typically evergreen, these trees feature needle- or scale-like leaves.

Construction, woodworking, and numerous CNC operations frequently include the use of softwoods. Some key characteristics of softwood include:

- Density: Softwood tends to have a lower density compared to hardwood, which makes it lighter and easier to work with.

- Grain Pattern: Softwood often exhibits a more prominent and straight grain pattern, which can give CNC projects a clean and uniform appearance.

- Availability: Softwoods are generally more abundant and grow faster than hardwoods, making them more readily available and cost-effective.

- Workability: Due to their lower density, softwoods are easier to cut, shape, and mill, making them suitable for CNC routing and other woodworking processes.

2. Budget-friendly and easier to mill:

One of the significant advantages of using softwood for CNC projects is its cost-effectiveness. Softwoods are usually more economical as compared to hardwoods so, softwood will be the ideal choice for budget-conscious projects.

Additionally, softwoods are easier to mill and work with, which can reduce machining time and costs. Their lower density allows for quicker cutting and smoother toolpaths during CNC routing.

3. Examples of softwood options for CNC projects:

There are different varieties of softwood, each with special qualities. Here are a few well-liked softwood choices frequently utilized in CNC woodworking projects:

- Pine: Pine is a popular softwood choice for CNC woodworking. It is readily available and comes in various grades, allowing for flexibility in project design. Pine CNC projects can range from intricate carvings to simple furniture pieces.

- Cedar: Cedar is a great material for outdoor CNC projects like garden furniture, fences, and decorative items because of its natural resistance to insects and rot.

- Spruce: Spruce is a lightweight and versatile softwood that is commonly used in CNC projects such as model making, cabinetry, and architectural trim.

- Fir: Fir is another softwood that is easy to work with and offers a balance of strength and affordability, making it suitable for a wide range of CNC woodworking applications.

- Redwood: Redwood is a premium softwood known for its beautiful reddish color and natural resistance to rot and decay. It is often used in high-end CNC projects, including outdoor furniture and decorative items.

With the right choice of softwood and CNC routing techniques, impressive and cost-effective woodworking projects can be achieved.

Considerations for Choosing Wood for CNC Projects:

Choosing the right wood for CNC projects is crucial to achieving the desired results and ensuring a successful outcome.

There are some factors we need to consider while choosing any wood for CNC projects:

A. Project Requirements and Complexity:

Choosing the right wood for CNC projects is crucial to achieving the desired results and ensuring a successful outcome.

Several considerations should be taken into account when selecting wood for CNC projects:

- Purpose and Function: Consider the intended use of the CNC project. Will it be functional furniture, decorative art, or a structural component?

- Size and Scale: The size and complexity of the project can influence the choice of wood. Larger projects may benefit from using stable and structurally strong woods, while smaller intricate designs may require a wood that is easy to work with and carve.

B. Budget and Cost Considerations:

- Wood Species: Different wood species vary in cost depending on their availability, demand, and desirability. Exotic hardwoods, for example, are often more expensive than common softwoods.

- Waste and Yield: Consider the yield and potential waste when working with specific wood types. Some woods might be more efficient, producing less waste and saving on material costs.

C. Machinability and Impact on CNC Machinery:

- Density and Hardness: Softer woods are generally easier to machine and cut with CNC routers compared to harder woods. High-density woods may require more powerful machinery and specialized cutting tools.

- Tool Wear: Harder woods can cause more wear on CNC router bits and tools, potentially increasing maintenance and replacement costs. Understanding the impact on CNC machinery is essential for long-term usage.

D. Appearance and Finishing Possibilities

- Grain and Texture: The grain pattern and texture of the wood can significantly affect the final appearance of the project. Some woods have distinct and attractive grain patterns, while others have a more uniform texture.

- Finishing Options: Certain woods take finishes and stains more readily than others, allowing for a broader range of finishing possibilities. Consider the desired finishing techniques and how the wood will respond to them.

- Aesthetics: A type of wood that enhances and matches the design of the project overall. The final aesthetic impression could be greatly influenced by the wood’s initial color and appearance.

In conclusion, selecting the right wood for CNC projects involves a careful assessment of project requirements, budget constraints, machinability, and desired aesthetics.

By considering these factors, CNC enthusiasts and woodworkers can ensure a successful and satisfying woodworking experience, resulting in beautiful and functional creations.

Get Help Choosing the Right Wood for CNC Projects

A. Yijin Solution – Trusted Partner for CNC Routing Services:

Yijin Solution is a reliable and experienced company that specializes in providing CNC routing services, and CNC wood turning services.

Yijin Solution has a solid reputation for offering top-notch customer service and creating high-quality products.

As trusted partners, they understand the importance of selecting the right wood for CNC projects to achieve optimal outcomes.

B. Over 15 Years of Experience with CAD/CAM Software and CNC Routers:

With over 15 years of experience in the industry, Yijin Solution boasts a team of skilled professionals well-versed in CAD/CAM software and CNC router technology.

Their expertise allows them to handle complex designs and efficiently execute CNC projects with precision and accuracy.

C. Expertise in Using All Types of Materials, Including Wood:

Yijin Solution has extensive expertise in working with various materials, including wood.

Our expert staff members are aware of the unique features of several wood species and how to use them to their advantage in CNC projects.

Due to their wide experience in this industry, they can provide a variety of solutions to our clients.

D. Assistance in Selecting the Best Type of Wood for Specific CNC Projects:

One of the valuable services provided by Yijin Solution is their assistance in selecting the most suitable wood for specific CNC projects.

They take into account project requirements, budget constraints, aesthetics, and other essential factors to help clients make well-informed decisions.

Whether it’s for functional furniture, decorative items, or structural components, Yijin Solution ensures that the chosen wood aligns with the project’s goals and design.

By relying on Yijin Solution’s experience and expertise, clients can rest assured that their CNC projects will be in capable hands.

From material selection to the final execution, Yijin Solution is dedicated to delivering top-notch results, resulting in beautiful and functional creations that meet their client’s expectations.

Conclusion

A. Recap of the Importance of Choosing the Right Wood for CNC Projects:

Selecting the right wood for CNC projects is of utmost importance as it directly impacts the outcome and success of the endeavor.

The choice of wood affects the project’s appearance, durability, machinability, and finishing possibilities.

Each wood type possesses unique characteristics that can either enhance or detract from the final visual impact and functionality of the project.

Considering factors such as project requirements, budget, machinability, aesthetics, and natural characteristics ensures that the chosen wood aligns perfectly with the project’s goals.

B. Emphasis on the Impact of Wood Selection on Project Results and Quality:

The wood selected for CNC projects significantly influences the overall quality of the end product.

Different woods vary in density, hardness, grain patterns, and response to finishing techniques, all of which affect how well they machine and how the finished piece looks and performs.

The wrong choice of wood can lead to issues such as tool wear, difficulty in machining, or a lackluster appearance, ultimately compromising the quality of the project.

On the other hand, the right wood choice can elevate the project, enhancing its beauty and functionality.

C. Encouragement to Seek Professional Advice for Successful CNC Woodworking:

For individuals embarking on CNC woodworking projects, seeking professional advice and assistance is highly recommended.

Expert CNC routing services, like those offered by Yijin Solution with their extensive experience and knowledge, can be invaluable in guiding wood selection, design considerations, and execution.

Their expertise ensures that the chosen wood aligns perfectly with the project’s requirements, resulting in successful and satisfying outcomes.

In conclusion, the choice of wood is a critical factor in the success of CNC projects. It impacts the project’s appearance, machinability, finishing possibilities, and overall quality.

Seeking professional advice from experienced CNC routing services, like Yijin Solution, can help individuals make informed decisions and achieve exceptional results in their CNC woodworking endeavors.

Recommended: Where To Find CNC Machining Services For Wood?

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569