Types of Threads

There are two types of threads: they are internal thread and external thread;

①According to the tooth shape threaded rod can be divided into 4 types, including triangular thread, trapezoidal thread, rectangular thread, a serrated thread;

②According to the number of threads, there are single-thread and multi-thread;

③According to the screw-in direction, it can be divided into 2 types: left-handed thread and right-handed thread.

The right-handed thread is not marked, and the left-handed screw is marked as LH, such as M24×1.5LH;

④According to different uses, it is divided into metric thread, pipe thread sealed with thread, non-threaded pipe thread, 60° tapered pipe thread, metric tapered thread, etc.

Metric Thread

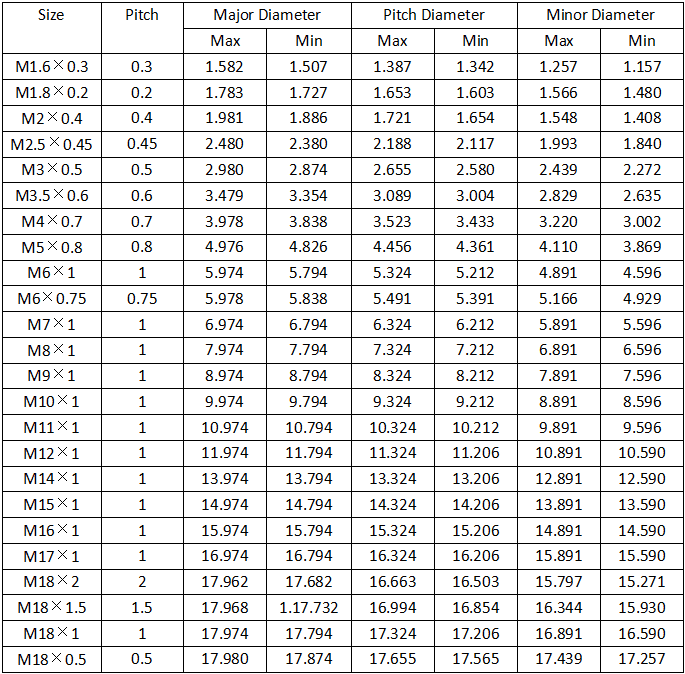

①Metric thread is represented by capital M, and the tooth angle is 2α=60° (α represents the tooth half-angle);

②Metric threads are divided into two types: coarse thread ordinary thread and fine thread ordinary thread;

③The mark of coarse thread generally does not indicate the pitch, such as M20 for coarse thread; the mark of the fine thread must indicate the pitch, such as M30×1.5 for fine thread, of which the pitch is 1.5.

④Ordinary threads are used for connection and fastening between mechanical parts. Generally, coarse threads are used for threaded connections.

The strength of fine threads is slightly higher than that of coarse threads of the same nominal diameter, and the self-locking performance is better.

⑤Metric thread marks: M20-6H, M20×1.5LH-6g-40, where M means metric common thread, 20 means the nominal diameter of the thread is 20mm, 1.5 means the pitch, LH means left-handed, 6H, 6g means the thread accuracy grade.

The uppercase precision grade code represents the internal thread, the lowercase precision grade code represents the external thread, and 40 represents the screwing length.

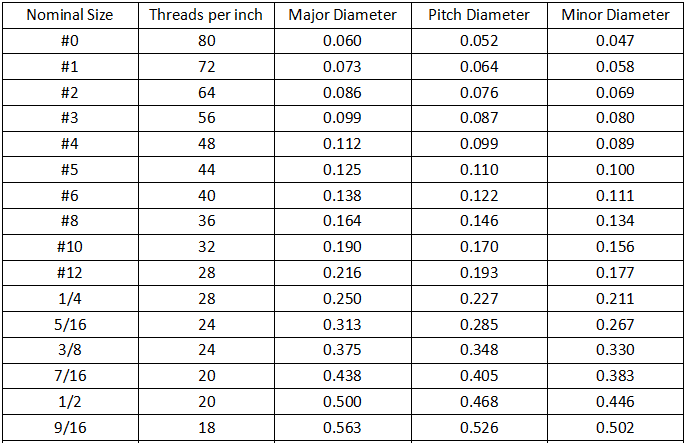

Table 1 Diameter/Pitch of Commonly Used Metric Coarse Threads

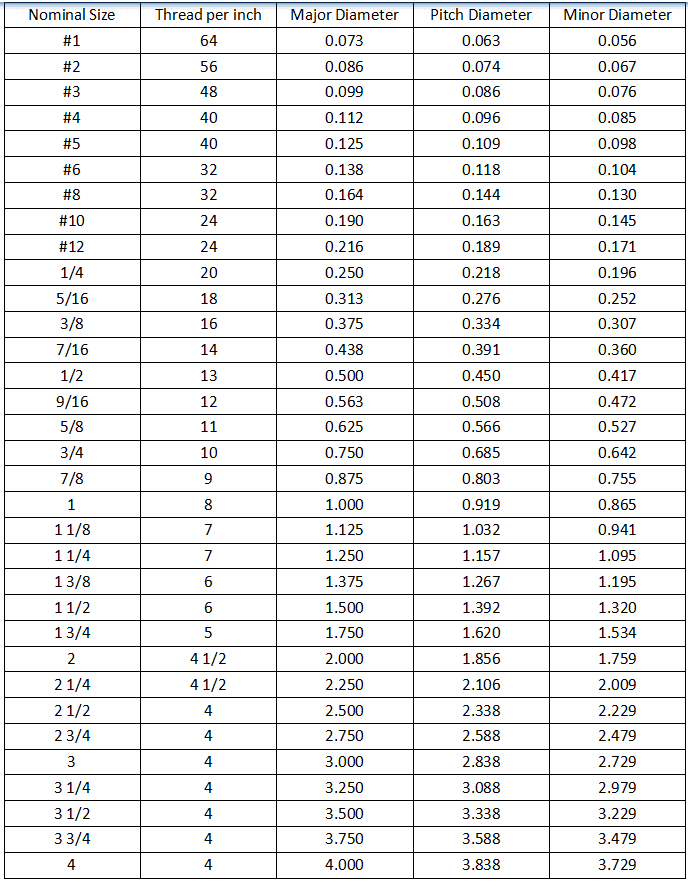

Table 2 Diameter/Pitch of Commonly Used Metric Fine Pitch Threads

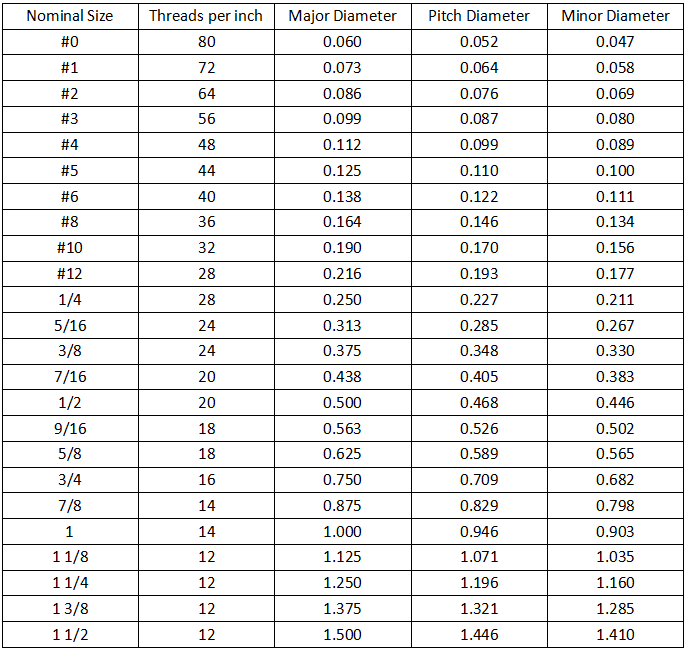

Table 3 Metric Thread Sizes Chart

Selection and Application of Unified Thread

- UNC coarse thread series, this series is usually used in mass-produced bolts, screws, nuts, and other general engineering. The coarse thread should be used for internal threads machined on low tensile strength materials such as castings, mild steel, and other soft materials to obtain the best trip strength for the internal thread. UNC thread is suitable for parts requiring quick disassembly or where corrosion and minor damage may occur.

- UNF fine thread series, this series is suitable for bolts, screws, nuts, and other applications where the coarse thread is not suitable. UNF male threads have a larger tensile stress area than coarse threads. When the tripping strength of the external thread and the matching internal thread is required to be equal to or higher than the tensile bearing capacity of the externally threaded parts, the fine-pitch thread should be used. If there is no requirement for the maximum strength of the external thread, the fine-pitch thread can also be used for the internal thread machined on low-strength materials, but the appropriate screw length must be selected to meet the above-mentioned tripping strength requirements.

- UNEF superfine thread series, this series is suitable for thin-walled pipes, thin nuts, short sleeves or short joints, and other occasions requiring short screwing length and smaller pitch. In general, it also applies to several situations specified above for fine thread.

- UN Constant Pitch Series, 4, 6, 8, 12, 16, 20, 28, and 32 teeth per inch various constant pitch series provide a wide range of special design requirements that cannot be met by the UNC, UNF, and UNEF series Diameter/pitch combinations. The constant pitch series is used for parts that have been assembled and disassembled several times or for parts that are easy to rethread. When selecting threads from the constant pitch series, the 8, 12, or 16 thread series listed in the table should be preferred as far as possible.

- For high-temperature and high-strength applications, for these applications, the coarse thread series is recommended for threads with a size of 0.25 to 1 inch, and the 8-thread series is preferred for threads larger than 1 inch.

Metric Thread Sizes Chart PDF Download

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569