CNC, or computer numerical control, machining, is a manufacturing technique that uses computer software that has already been written to control the movement of tools and machines while producing parts and components that are specifically created for a customer.

A. Definition and Importance of CNC Machining

CNC machining is crucial in modern manufacturing due to its preCNC machines can help eliminate materialcision, efficiency, and versatility. It allows for the production of complex and accurate parts with minimal human intervention, leading to higher consistency, reduced error rates, and faster production times.

This technology finds applications in various industries, including aerospace, automotive, medical, and electronics, contributing significantly to advancements in product design and innovation.

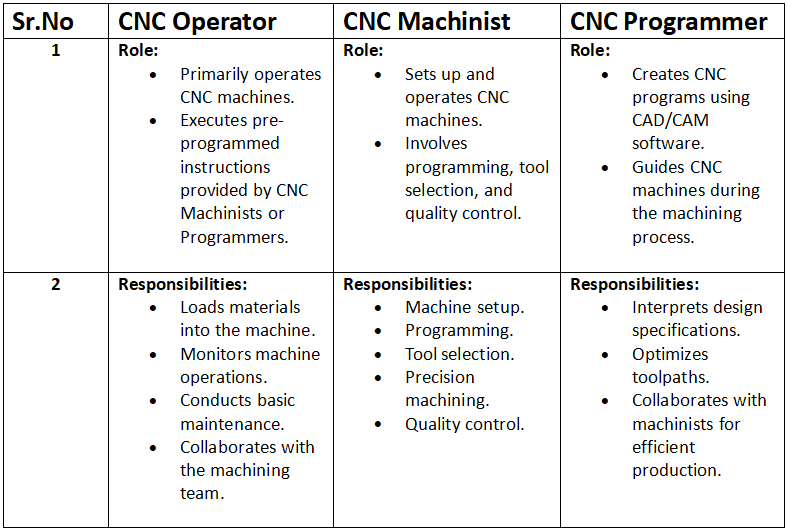

B. Overview of the Roles of A CNC Machinist, CNC Operator, and CNC Programmer

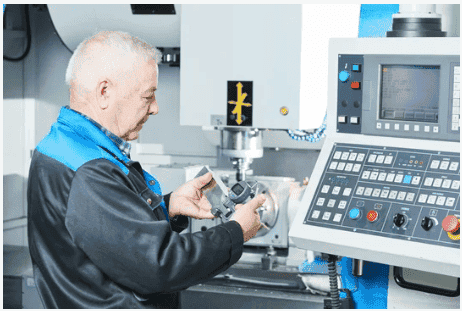

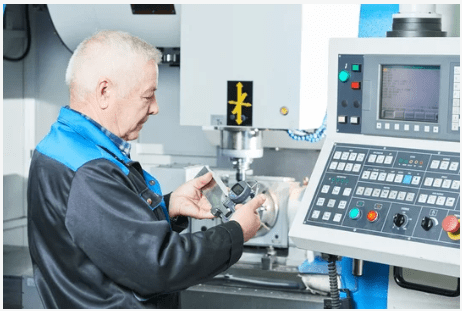

CNC Machinist: A CNC Machinist is responsible for setting up and operating CNC (Computer Numerical Control) machines. Their duties include interpreting blueprints, selecting appropriate tools, loading materials into the machine, and monitoring the machining process. Machinists also perform routine maintenance on machines and inspect finished products for quality and accuracy.

CNC Operator: A CNC Operator works closely with CNC machines, focusing on the execution of machining operations. Their responsibilities include loading raw materials into the machine, adjusting machine settings, and monitoring the production process. CNC Operators need a good understanding of machine controls and may perform basic maintenance tasks. They often work under the supervision of CNC Machinists or CNC Programmers.

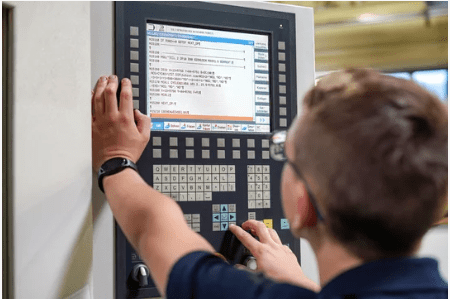

CNC Programmer: CNC Programmers are responsible for creating the instructions (G-code) that CNC machines follow to produce parts. They start with product designs and blueprints, then use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to generate the code. CNC Programmers need a deep understanding of machining processes, materials, and tooling. Their role is crucial in optimizing efficiency, minimizing errors, and ensuring the CNC machines produce parts to the required specifications.

II. What is A CNC Operator?

A CNC Operator is an essential role in the field of manufacturing, specifically in the operation of Computer Numerical Control (CNC) machines.

This position involves a range of responsibilities to ensure the accurate and efficient production of machined parts.

A. Responsibilities: CNC Operators play a crucial role in the day-to-day operations of CNC machines. Their responsibilities include:

- Machine Setup: Prepare CNC machines for operation by loading necessary tools and materials, and securing workpieces in the machine.

- Programming Input: Input program data into the CNC machine, including loading the appropriate CNC code and making any necessary adjustments.

- Monitoring Operations: Keep a close eye on the machining process, ensuring that machines are running smoothly and making necessary adjustments to settings if needed.

- Quality Control: Inspect finished products to ensure they meet the specified quality standards and make adjustments to the machine as required to correct any issues.

- Maintenance: Perform routine maintenance tasks on CNC machines, such as cleaning, lubricating, and replacing worn tools or components.

- Safety Compliance: Adhere to safety protocols to maintain a secure working environment, including wearing appropriate personal protective equipment (PPE).

- Documentation: Maintain accurate records of production runs, machine settings, and any issues encountered during the machining process.

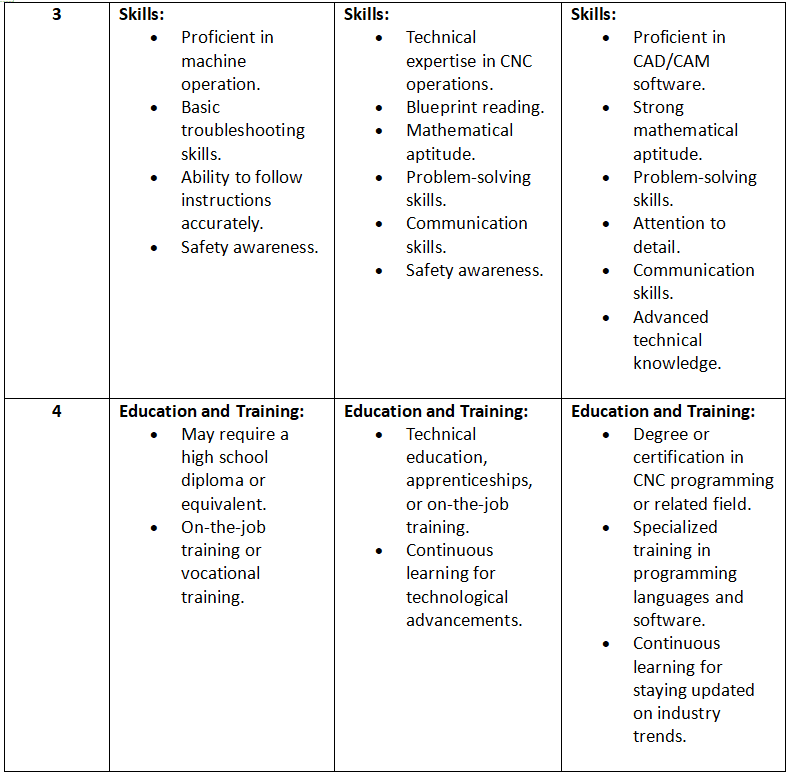

B. Required Skills and Knowledge: To excel as a CNC Operator, individuals should possess the following skills and knowledge:

- Technical Aptitude: Understand the basic principles of CNC machining and be able to interpret technical drawings and blueprints.

- Machine Operation: Proficiently operate CNC machines, including loading materials, setting up tools, and inputting program data.

- Problem Solving: Ability to troubleshoot and address issues that may arise during the machining process, ensuring continuous and efficient production.

- Attention to Detail: Thoroughly inspect finished products for quality, identifying any deviations from specifications.

- Communication: Effectively communicate with CNC Machinists, CNC Programmers, and other team members to relay information about the machining process and any issues encountered.

- Safety Awareness: Adhere to safety guidelines and protocols, demonstrating a commitment to maintaining a safe working environment.

- Adaptability: Be open to learning new techniques and adapting to changes in machine setups or programming requirements.

A skilled CNC Operator is essential to the smooth functioning of CNC machining processes, contributing to the overall efficiency and quality of manufactured parts.

III. What is a CNC Machinist?

A CNC Machinist is a skilled professional in the field of manufacturing who specializes in operating and setting up Computer Numerical Control (CNC) machines.

These machines are automated tools that follow pre-programmed instructions to perform precise cutting, shaping, and finishing of materials, such as metal, plastic, or wood.

The CNC Machinist plays a pivotal role in transforming raw materials into finished products with high precision and accuracy.

A. Responsibilities:

- Machine Setup: CNC Machinists are responsible for setting up CNC machines, including loading the necessary tools and securing raw materials for machining.

- Programming: Interpret and implement CNC code, generated by CNC Programmers, to control the movements and actions of the machine.

- Tool Selection: Choose appropriate tools for specific machining tasks, considering factors such as material, cutting speed, and precision requirements.

- Precision Machining: Operate CNC machines to precisely cut, shape, and finish materials according to engineering blueprints and specifications.

- Quality Control: Inspect finished products to ensure they meet quality standards and make adjustments to maintain accuracy and precision.

- Problem Solving: Troubleshoot issues that may arise during the machining process, making necessary adjustments to ensure optimal performance.

- Collaboration: Work closely with CNC Programmers, CNC Operators, and other team members to optimize machining processes and achieve production goals.

- Maintenance: Perform routine maintenance on CNC machines, including cleaning, lubrication, and replacing worn or damaged tools.

B. Required Skills and Knowledge:

- Technical Proficiency: Possess a deep understanding of CNC machine operations, including programming, setup, and troubleshooting.

- Blueprint Reading: Interpret and understand complex engineering drawings and specifications.

- Tool Knowledge: Familiarity with a variety of tools and their applications, and the ability to select the right tools for specific machining tasks.

- Mathematical Skills: Strong mathematical aptitude, including knowledge of geometry, trigonometry, and calculations related to machining processes.

- Attention to Detail: Pay meticulous attention to detail to ensure precision and accuracy in the machining process.

- Problem-Solving: Analytical and quick-thinking skills to troubleshoot issues and optimize machining efficiency.

- Communication: Effectively communicate with team members, including CNC Operators and CNC Programmers, to convey information about machine setups and production requirements.

- Safety Consciousness: Adhere to strict safety protocols to ensure a secure working environment.

CNC Machinists play a key role in the manufacturing process, combining technical expertise with practical skills to produce high-quality machined components.

IV. What is A CNC Programmer?

A CNC Programmer is a skilled professional responsible for translating engineering designs and specifications into instructions that Computer Numerical Control (CNC) machines can understand and execute.

This role is integral to the manufacturing process, as CNC Programmers play a key role in determining how CNC machines produce precise and complex parts.

A. Responsibilities:

- Interpreting Designs: Collaborate with engineers and designers to understand product specifications, interpret design blueprints, and convert them into machine-readable code.

- Programming: During the machining process, all actions are controlled by CNC code which is developed by programming by CAD and CAM software.

- Optimizing Toolpaths: Develop efficient toolpaths that maximize machining efficiency while ensuring the desired precision and surface finish.

- Material Selection: Determine the appropriate cutting tools, machining speeds, and feeds based on the material being used and the desired outcome.

- Quality Assurance: Conduct simulations and tests to verify the accuracy of the CNC code and ensure that the machined parts meet the specified tolerances and quality standards.

- Collaboration: Work closely with CNC Machinists and Operators to fine-tune programs, address any issues during production, and implement improvements for optimal machine performance.

- Documentation: Maintain accurate records of CNC programs, tool selections, and any modifications made to optimize machining processes.

- Continuous Improvement: Stay updated on advancements in CNC technology, machining techniques, and software to incorporate improvements in programming methods.

B. Required Skills and Knowledge:

- Technical Proficiency: In-depth knowledge of CNC machining processes, including an understanding of machine capabilities, tooling, and material properties.

- CAD/CAM Skills: Proficient in computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create and modify CNC programs.

- Mathematical Aptitude: Strong mathematical skills for precise calculations related to toolpaths, speeds, feeds, and dimensional tolerances.

- Problem-Solving: Analytical mindset to identify and address issues in CNC programs, optimizing efficiency and quality.

- Communication: Effective communication with design and production teams to ensure CNC programs align with design specifications and production requirements.

- Attention to Detail: Meticulous attention to detail to create accurate and error-free CNC programs.

- Adaptability: Ability to adapt to new technologies, machining processes, and software updates to enhance programming capabilities.

- Safety Awareness: Understanding of safety protocols to ensure that CNC programs are developed with consideration for operator safety.

CNC Programmers play a critical role in the manufacturing process, translating design concepts into precise instructions for CNC machines, ultimately influencing the quality and efficiency of the production process.

V. CNC Operator vs. CNC Machinist vs. CNC Programmer

VI. Career Outlook and Advancement Opportunities

A. Growth Potential for CNC Machinists and CNC Programmers:

CNC Machinists:

- Growth Potential: The manufacturing of medical devices, automobiles, and aircraft will all likely continue to have a consistent need for CNC machinists.

- Specialization Opportunities: Machinists can specialize in areas like multi-axis machining, CNC programming, or work with specific materials, enhancing their value in the job market.

- Technological Advancements: Continuous technological advancements in CNC machining may lead to increased demand for machinists who can adapt to new tools and processes.

CNC Programmers:

- Growth Potential: The demand for CNC Programmers is likely to increase due to the growing emphasis on automation and precision manufacturing.

- Industry Demand: Industries such as aerospace, defense, and medical manufacturing often seek skilled CNC Programmers to optimize production processes.

- Advanced Programming Skills: Programmers with advanced skills in CAM software, and simulation tools, and knowledge of emerging technologies like Industry 4.0 may experience heightened demand.

B. Potential Pathways to Becoming a CNC Machinist or CNC Programmer:

CNC Machinist:

- Technical Education: Pursue a certificate or diploma in CNC machining from a technical or vocational school.

- Apprenticeships: Gain hands-on experience through apprenticeships, learning under experienced machinists.

- On-the-Job Training: Some machinists start as machine operators and progress to the role of machinist through on-the-job training.

- Continuous Learning: Stay updated on the latest machining technologies and techniques through workshops and additional training.

CNC Programmer:

- Education: Obtain a degree or certification in CNC programming, computer-aided design (CAD), or a related field.

- Advanced Training: Undertake specialized training in CNC programming languages, CAM software, and simulation tools.

- Industry Certifications: Acquire industry-recognized certifications to validate programming skills and enhance employability.

C. Advancement Prospects for Both Roles:

CNC Machinists:

- Lead Machinist: Advance to a lead machinist role, overseeing a team of machinists and managing production processes.

- Specialization: Specialize in areas such as CNC programming, quality control, or tooling.

- Supervisory Roles: Move into supervisory or management positions within the manufacturing environment.

CNC Programmers:

- Senior Programmer: Progress to a senior programmer role, taking on more complex projects and responsibilities.

- Engineering Roles: Go on to engineering roles where you may help with the planning and improvement of production procedures.

- Management: Transition into management roles, overseeing programming teams or entire manufacturing operations.

Both CNC Machinists and CNC Programmers can enhance their career prospects by staying updated on industry trends, acquiring additional certifications, and adapting to advancements in CNC technology.

Continuous learning and a commitment to mastering new skills are key to long-term success and advancement in these dynamic roles.

VII. Conclusion

A. Summary of the Differences between CNC Machinists, CNC Operators, and CNC Programmers:

1. CNC Machinist:

- Role: Focuses on setting up and operating CNC machines, including programming, tool selection, and quality control.

- Responsibilities: Involved in the entire machining process, from setup to production, and often responsible for troubleshooting and maintaining machines.

2. CNC Operator:

- Role: Primarily operates CNC machines, executing the programmed instructions provided by CNC Machinists or Programmers.

- Responsibilities: Involves loading materials, monitoring machine operations, conducting basic maintenance, and collaborating with the machining team.

3. CNC Programmer:

- Role: Creates CNC programs using CAD/CAM software to guide the movements of CNC machines during the machining process.

- Responsibilities: Involves interpreting design specifications, optimizing toolpaths, and collaborating with machinists to ensure efficient and accurate production.

B. Considerations for Career Choice in CNC Machining:

1. Interest and Aptitude:

- Machinist: Well-suited for individuals interested in hands-on work, problem-solving, and a detailed understanding of machining processes.

- Programmer: Ideal for those with a strong interest in computer programming, design interpretation, and optimizing manufacturing processes.

2. Education and Training:

- Machinist: Pathways include technical education, apprenticeships, and on-the-job training.

- Programmer: Requires education in CNC programming, computer-aided design, and specialized training in programming languages and software.

3. Skill Set:

- Machinist: Requires technical expertise, blueprint reading, mathematical skills, and hands-on precision machining skills.

- Programmer: Requires proficiency in CAD/CAM software, strong mathematical aptitude, problem-solving skills, and a keen attention to detail.

4. Career Advancement:

- Machinist: Advancement opportunities include specialization, supervisory roles, and potential progression to lead machinist positions.

- Programmer: Advancement possibilities include senior programming roles, transitioning to engineering positions, and potential management roles.

5. Industry Demand:

- Machinist: Steady demand in manufacturing sectors such as aerospace, automotive, and medical devices.

- Programmer: Growing demand due to increased automation and emphasis on precision manufacturing.

6. Adaptability:

- Machinist: Requires adaptability to new machining technologies and tools.

- Programmer: Requires staying updated on emerging technologies and software advancements in CNC programming.

Choosing a career path in CNC machining depends on individual preferences, skills, and career aspirations. Both CNC Machinists and CNC Programmers play vital roles in the manufacturing industry, contributing to the production of high-precision components essential in various sectors.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569