In today’s globalized manufacturing landscape, China has emerged as a dominant player in the field of aluminium CNC machining.

The nation is a top choice for companies looking for high-quality aluminium CNC machining services due to its strong industrial infrastructure, competent workforce, and cost-effective manufacturing capabilities.

However, with a plethora of suppliers to choose from, the task of selecting a reliable partner can be daunting.

Ensuring that your chosen Chinese aluminium CNC machining supplier meets your quality, cost, and delivery requirements is paramount for the success of your project.

In this guide, we will walk you through the essential considerations and strategies to help you navigate this crucial decision-making process.

Discover how to choose reliable Chinese aluminium CNC machining suppliers, ensuring your project’s success while mitigating potential risks and challenges.

Importance of Finding Reliable Aluminium CNC Machining Suppliers in China:

Finding reliable aluminium CNC machining suppliers in China is of paramount importance for businesses seeking precision-engineered components and cost-effective manufacturing solutions.

Below are the some key importance of finding reliable Aluminium CNC Machining Suppliers in China:

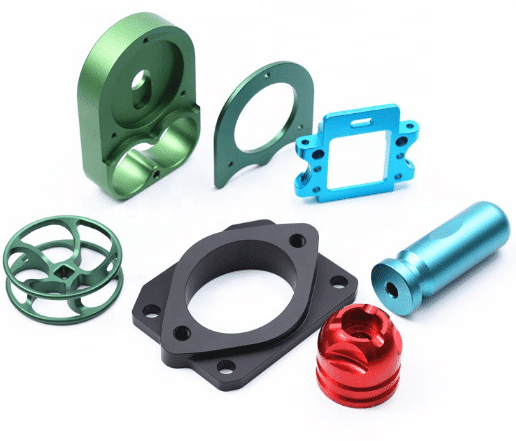

- Quality Assurance: Reliable suppliers adhere to stringent quality control standards, ensuring that the aluminium components they produce meet or exceed industry specifications. The overall effectiveness and durability of your products depend on high-quality parts.

- Cost Efficiency: In the industrial sector, China is renowned for its affordable prices. Your bottom line will benefit from working with a dependable provider that can give you access to affordable machining services without sacrificing quality.

- Timely Delivery: Delays in production and delivery can disrupt your supply chain and affect your ability to meet customer demands. Reliable suppliers in China are more likely to adhere to agreed-upon timelines, helping you maintain a consistent workflow.

- Communication and Collaboration: For a project to be successful, effective communication with your supplier is essential. Reliable suppliers are more likely to have a proficient team that can bridge language and cultural gaps, facilitating smooth collaboration and problem-solving.

- Customization and Flexibility: Depending on your project’s unique requirements, you may need customized machining solutions. Reliable suppliers are often more willing and capable of accommodating special requests and offering flexibility in production processes.

- Reduced Risk: A trustworthy supplier can help mitigate risks associated with production issues, quality defects, or intellectual property concerns. This is especially important when operating in a foreign market like China.

- Long-term Partnerships: Building a strong, long-term relationship with a reliable supplier can lead to benefits such as improved terms, priority production slots, and a better understanding of your business needs.

How To Choose Reliable Chinese Aluminium CNC Machining Suppliers

Selecting a trustworthy Chinese CNC machining supplier for aluminum is a crucial choice that can have a big impact on the success of your project.

Here’s a step-by-step guide to help you make an informed choice:

1. Define Your Requirements:

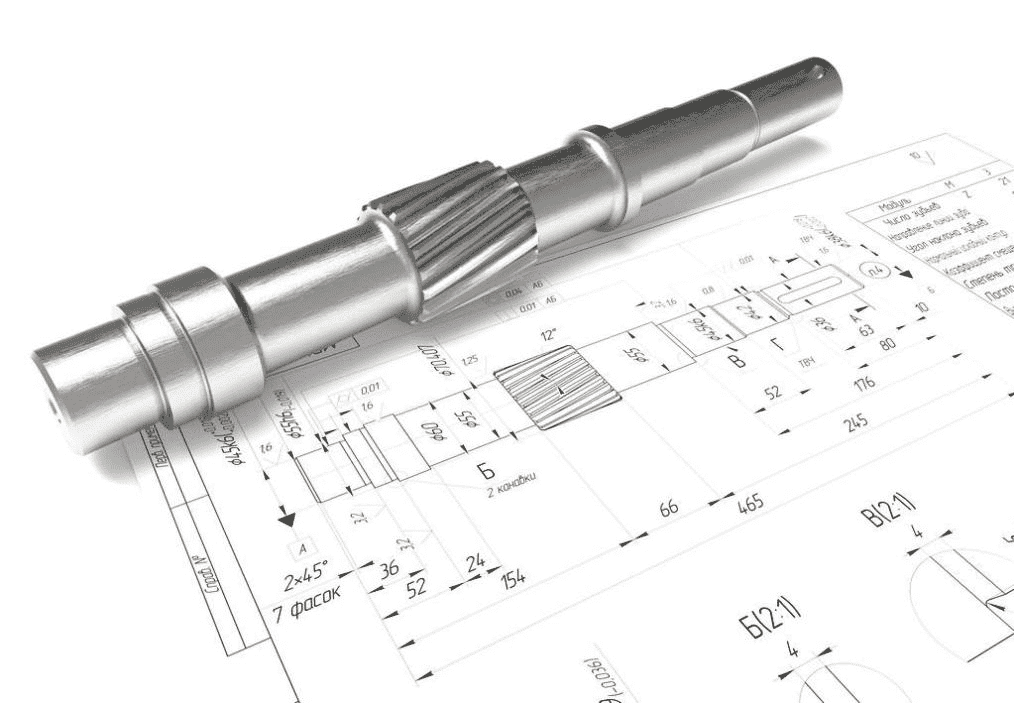

- Clearly outline your project’s specifications, including material type, machining tolerances, volume requirements, and quality standards.

2. Research and Identify Potential Suppliers:

- Use online directories, industry forums, trade shows, and recommendations from peers to create a list of potential suppliers in China. Consider factors like location, size, and specialization.

3. Evaluate Supplier Credentials:

- Ask for certifications like ISO 9001 for quality management and ISO 14001 for environmental management and other certification like authorization letter or excellence certification. These accreditations prove a dedication to excellence and environmental responsibility.

4. Assess Technical Capabilities:

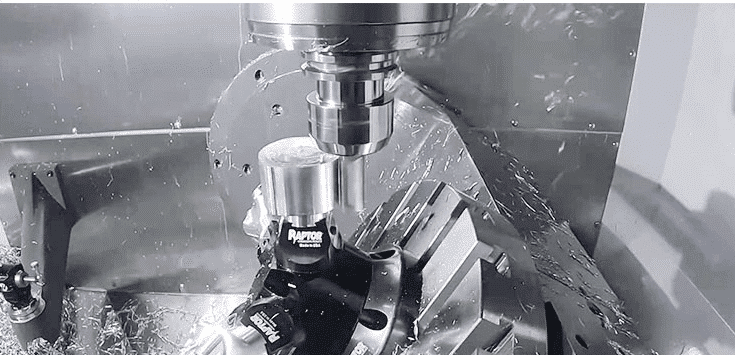

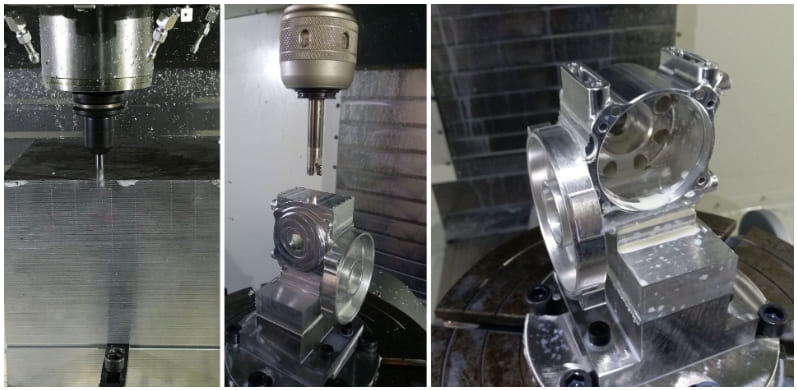

- Review the supplier’s machining equipment, technology, and capabilities. Verify that they have the CNC tools and software needed to finish your job.

5. Quality Control and Inspection Procedures:

- Request information about the supplier’s quality assurance procedures. Ask for information on inspection equipment, in-process checks, and final product testing.

6. Request References and Samples:

- Ask for trade references from past or current customers which will give us clear idea that this supplier is working or already worked with this references in past. Additionally, request samples of their work to assess the quality of their craftsmanship.

7. Visit the Facility (If Possible):

- If possible, plan a trip to the supplier’s location. This offers a chance to evaluate their workforce’s abilities, organization, cleanliness, and infrastructure.

8. Communication and Language Skills:

- Assess the supplier’s language and communication abilities. The success of a project and the resolution of problems depend on effective communication.

9. Supply Chain and Logistics:

- Discuss logistics and supply chain capabilities with the supplier. Ensure they can handle shipping, customs, and other logistical aspects seamlessly.

10. Cost and Pricing Transparency:

- Request detailed quotes and pricing breakdowns. Sometimes, for low cost they might be compromise the quality of item so, we need to ensure that quality of item not be co promised anyhow.

11. Negotiate Terms and Agreements:

- Discuss payment terms, lead times, and any special requirements. Make sure that a precise and binding contract contains a written statement of all terms and agreements.

12. Intellectual Property Protection:

- Address intellectual property concerns in the contract, including confidentiality agreements and protection of your proprietary designs and information.

13. Scalability and Long-Term Partnership:

- Consider the supplier’s ability to scale production if your project grows. Look for a partner interested in establishing a long-term relationship.

14. Feedback and Reputation:

- Research online reviews, testimonials, and any negative feedback about the supplier. This can offer insights into their reputation and past performance.

15. Risk Assessment:

- Assess potential risks associated with the supplier, such as political instability, economic factors, or supply chain disruptions.

16. Continual Monitoring:

- Once you’ve chosen a supplier, maintain open communication and periodically assess their performance to ensure ongoing reliability.

Thorough research, diligence, and careful evaluation of different criteria are necessary when selecting a reputable Chinese CNC machining supplier for aluminum.

By following these steps, you can increase the likelihood of forming a successful partnership and obtaining high-quality aluminium components for your projects.

Conclusion

In conclusion, choosing a trustworthy Chinese supplier for CNC machining aluminum is a crucial choice that can have a big impact on how successful your company is.

It involves a thorough evaluation process encompassing factors such as quality, communication, cost, and trustworthiness.

By following a systematic approach that includes researching potential suppliers, assessing their capabilities, and establishing clear expectations, you can mitigate risks and ensure a productive and enduring partnership.

The ideal provider will meet your needs specifically and offer solutions that are timely and cost-effective in addition to high-quality CNC machined aluminum components.

They will place a priority on good communication and follow international standards, and protect your intellectual property.

Ultimately, the choice of a dependable Chinese aluminium CNC machining supplier can enhance your product quality, streamline your production processes, and contribute to your business’s long-term success in today’s competitive global marketplace.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569