Thread connection is widely used in the connection and fixation of product parts because of its low cost, simple structure, convenient disassembly and assembly, reliable connection, and other characteristics.

A loose bolt may cause parts to loosen abnormal sounds, fall-off damage, and other situations, even endanger personal safety, and may even put the whole production plant at a standstill, and make the company suffer heavy losses.

So, what is the main cause of bolt loosening?

Today, Yijin Hardware will carry out the cause investigation and verification analysis, and summarize the corresponding anti-loosening measures.

Cause Analysis

1. Bolts

If the bolt material strength is lower than the standard, in the tightening process, with the increase of bolt pre-tightening force, the clamping force between the joint components also increases, and bolt elastic deformation occurs in this process.

When the yield point is reached, the bolt begins to plastic deformation, and with the increase of pre-tightening force, the increment of clamping force becomes smaller or even unchanged, and then gradually becomes smaller, resulting in bolts loosening.

If the bolt pitch is not reasonable, although it can meet the requirements of self-locking and anti-loosening, due to the pre-tightening force required by the joint assembly being too large, the bolt selected under the action of the pre-tightening force beyond the limit, the screw tooth damage (or screw hole damage), to bolt loose.

If the bolt type is too small or the bolt grade is too low, the bolt cannot offset the action of the axial tensile force and radial shear force between the joint components under the working state, and the repeated cycle of the force eventually makes the bolt fatigue, plastic deformation, the pre-tightening force is reduced, and the bolts loosening occurs.

Thread size also affects the size of the bolt preload obtained, too large thread with a threaded hole fits too tight, and the same torque in the case of a small preload, the tightening effect is low;

When the thread is too small and the threaded hole is too large, the contact area of the screw tooth in the thread pair is too small, and the screw tooth under the same pre-tightening force is too large, which may lead to the screw tooth collapse and release after the force of the joint assembly.

2. Design

The pre-tightening force that the bolt can achieve in the tightening process directly determines the clamping force between two connecting parts.

The mating mechanical analysis shows that under the condition of static load, the general thread meets the self-locking condition and will not cause bolts to loosen.

But, variable load, vibration, and impact are the main factors causing bolt loosening;

Designers do not fully consider the actual working conditions of this element, and easy to appear design requirements can not meet the requirements of the situation, resulting in the bolt loosening.

Serious compression will make the bolt preload reduce or lose the preload, resulting in the loosening of the nut or bolt. The thread contact interface is usually uneven.

After preloading, the inner and outer threads can’t complete contact, and the micro-convex body on the inner (outer) threads may be embedded into the concave area of the outer (inner) threads.

Under the action of periodic external force, the reciprocating micro-sliding motion of internal and external threads will occur, resulting in adhesive shedding and loss of pre-tightening force, which is called fretting wear loss.

After tightening, the bolt pre-tightening force will produce convex point collapse and permanent plastic deformation, so that the clamping length of the bolt will be reduced, and finally lead to the reduction of the bolt pre-tightening force.

3. Tools

Tool failure is one of the main causes of bolt loosening. A Pneumatic wrench is a common tool for pre-tightening bolts equipped by the company.

After investigation, the main reasons for the failure of the pneumatic wrench are as follows:

First, the employee does not normally use the tool, resulting in abnormal wear, such as the continuous impact of the pneumatic wrench after the bolt is tightened in place;

The second is that the supporting equipment is not used correctly or has failed, and the tool has been in a non-maintenance environment for a long time, such as directly connecting the pneumatic wrench to the compressed air pipeline without the pneumatic triplet.

Improper tool configuration is also one of the reasons for bolt loosening. The company uses a large-range torque wrench to assemble low-torque bolts.

Because the torque value corresponding to each scale is too large, the precise torque cannot be grasped, and the bolt tightening torque may be insufficient, resulting in bolt loosening.

4. Operator

The bad working habits of the operator are one of the direct causes of bolt loosening. After investigation, the operator’s bad working habits are in many aspects.

One is that the continuous impact of the pneumatic wrench is still maintained after the bolt is tightened in place, destroying the supporting surface of the joint assembly (it may also be the deformation of the flat pad and the failure of the spring pad);

The second is that the operator is cutting corners, not using torque wrenches, or not pressing the thread to tighten the glue or to tighten the bolts in an order that is not required.

Third, the operator diagram assembly is convenient to switch to other kinds of bolts.

5. Processing defects and other problems

The chamfering of bolt mounting holes is too large, which may occur when the size of mounting holes is too large.

In addition, the surface of the joint assembly is uneven, so that the bolt and the joint assembly are not completely fit, and can not play enough friction;

When there is a relative slip between the bolt and the joint assembly, the joint surface will wear, eventually leading to a decrease in preload, resulting in bolt loosening.

Bolts Anti-Loosing Measures

Design Process

Fully consider the bolt installation position of the operating requirements, considering the weight of the joint component, load, safety standards, and other factors, select the appropriate specifications of the bolt, accurately analyze and calculate the size of the preload, reserve enough working space to ensure the bolt connection safe and reliable.

Adopt an anti-loosen bolt design. Combined with the company’s actual situation, the following anti-loose design can be selected:

- The locking mode of the elastic gasket;

- The Double nut locking mode;

- The locking mode of the non-metallic insert locking nut is adopted.

- Mechanical locking mode with slotted nut and split pin;

- The locking method of applying thread-fastening glue is adopted.

To avoid the deformation and loosening of the supporting surface of the joint assembly, a suitable through-hole (screw hole) can be selected, suitable gasket combination, flange bolt selection, and optimization of the material of the joint assembly can be adopted.

When using the “bolt and nut” fastening method, welding one of them to the joint assembly is preferred.

Clear assembly requirements, configure appropriate tools and fixtures, to ensure the consistency of production, and eliminate workers by feeling and experience to judge the operation effect.

Specific Requirements are as Follows

- Tighten the 8.8 bolts with a pneumatic wrench;

- When the pneumatic wrench ratchet slippage sounds 1 ~ 2 seconds, must immediately loosen the work button;

- Select the appropriate pneumatic wrench gear according to the recommended torque table of grade bolts;

- Bolts of grade 9, grade 12.9, and with special requirements shall be tightened according to the calibration torque with a torque wrench;

- The plane of the torque rotation direction should be perpendicular to the axial direction of the bolt;

- Apply thread fastening glue;

- Operate according to the calibrated assembly sequence;

- After assembly, there is a gap around the joint surface that belongs to an unqualified phenomenon.

- Production Process

Materials with appearance defects are not allowed to be used in critical parts. In the process of machining, the correct tap is selected according to the accuracy requirements of the screw hole, and then the tap with serious wear is replaced in time to eliminate processing defects and ensure the quality of the screw hole.

In the process of welding and painting, pay attention to shielding screw holes to prevent thread damage and pollution and affect the final assembly effect.

Strictly implement the design requirements, according to the provisions of the correct use of tools and fixtures, eliminate workers by feeling and experience to judge the operation effect.

Check whether the thread is intact before assembly, and check whether there are gaps around the joint surface after assembly.

New employees must master basic assembly skills before they start work.

Commonly Used Bolts Screws Loose Prevention Method

Friction Locking

Double nut anti-loose, spring washer, self-locking nut, etc.

1. Add A Flat Washer

A washer refers to the part between the connecting piece and the nut, generally, a flat metal ring is used to protect the surface of the connecting piece from nut abrasion, and scattered nut pressure on the connecting piece.

2. Add A Flat Washer and Spring Washer

Spring washers are widely used in load-bearing and non-load-bearing structures of general mechanical products. They are suitable for assembling and disassembling frequent parts, but the anti-loosening ability of spring washers is very low!

3. Self-Locking Nut

The common nut in the use process is due to vibration and other reasons, to prevent this phenomenon, the invention of the self-locking nut.

According to the functional classification of the type of self-locking nuts embedded in nylon ring, with a neck closing, plus metal anti-loose device, they are effective torque type anti-loose nuts.

Locknuts are difficult to screw because of their feature.

4. Double Nut Anti-Loose

Anti-loosening of double nuts is two nuts with the same rotation in tightening, and then the two nuts according to the direction of the arrow in the picture of the screw, so that the top force between the two nuts, so that the nut under both friction and washer and friction with the second nut, double friction to achieve the effect of pre-tightening.

5. Elastic Ring Locknut

Inserts fiber or nylon at the screw entry to increase friction.

Mechanical Locking

Cotter pin and hexagon slotted nut, stop washer, series wire, etc.

A mechanical anti–low method is more reliable and should be used for important connections.

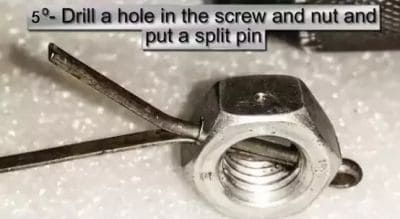

1. Drill A Hole in the Screw and Nut and Put A Split Pin

In machinery, the pin is mainly used for assembly positioning and also can be used for connection, anti-loose grade safety device overload shear connection.

The types of pins are cylindrical pins, conical pins, pins with holes, split pins, and safety pins.

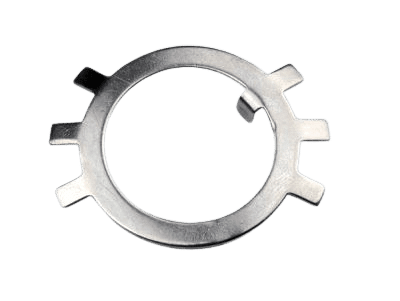

2. Round Nuts and Internal Tab Washer

Insert the inner tongue of the washer into the groove of the bolt (shaft), and insert one of the outer tongues of the washer into the groove of the nut after tightening the nut.

3. Internal Tab Washer

After the nut is tightened, the single-lug or double-lug stop washer is bent and pressed to the side of the nut and the connected piece respectively to prevent loosening.

If two bolts need double interlocking, double-stop gaskets can be used.

4. Series Steel Wire Anti-Loose

Put the low carbon steel wire into the hole of the screw head, and connect the screws in series, so that they brake each other.

This structure requires attention to the direction of wire penetration.

Permanent Locking

Spot welding, riveting, bonding, etc.

In addition, there are other ways to prevent the loss, such as: in the screw thread coated with liquid adhesive, at the end of the nut inlaid nylon ring, riveting punching loosening. Mechanical and friction anti-loosening is called removable anti-loosening, and permanent anti-loosening is called non-removable anti-loosening.

1. Punching Method to Prevent Looseness

The screw thread is destroyed at the end of the thread after the nut is tightened.

2. Glue Locking-Nut Locking Liquid

Apply the nut anti-loosening solution to the tightening place of the bolt, and then screw the nut. After self-curing, the anti-loosening effect is good.

Learning More

Locknut Principle

Locknut, the self-tightening nut is a common fastening anti-loose nut, its principle is very simple, the traditional 60-degree tooth tip end has a 30-degree wedge, this structure makes the bolt tighten with the nut, and the Yin and Yang threads will get greater friction than the traditional thread, so it has a good anti-loose effect.

Although the locknut can be a good solution to the problem of easy loosening of the nut, in use if you do not pay attention to and maintenance, regular maintenance, the anti-loose nut will also appear to different problems due to its shortcomings, so the following details for you to introduce several ways to prevent loose nut to avoid slipping loose.

Conclusion

In complex working conditions, bolt loosening prevention needs to take many factors into comprehensive consideration. Bolt loosening prevention measures are not single but may be a combination of various methods.

Only by identifying the root cause of bolt loosening, can appropriate loosening prevention methods be selected according to local conditions.

This article mainly aims at the assembly process of the equipment before delivery research analysis, statistical analysis from several aspects of reasons, and presents some effective thread locking methods, these methods have been applied on-site, and the promotion and locking effects are good.

We hope this information will help you. For more new information click the box below and get YIJIN Hardware experts’ help.

Thank you for reading.

Learn More:

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569