The custom silver parts customer is from UAE.

Material Used: Silver S925

Product Difficulties: The product is small in size and extremely precise, the silver material is expensive and the surface is easily scratched.

Taking all these into consideration, we provide our customers with two solutions.

- Use casting and machining to complete this product. The purpose is to minimize the waste of the surface silver S925 material and reserve an appropriate finishing turning allowance on the casting to save the cost for customers.

Problems: Because silver S925 absorbs a large amount of oxygen when it melts at high temperatures, silver S925 contains only a very small amount of antioxidants, and the parts are too thick, so the oxidation produced such as red marks, air holes, sand holes, and other problems, and these problems can only be reflected after secondary processing. In order to facilitate the subsequent mass production of this product, Yijin Hardware discards this solution.

- Totally use Machining Process. Create the mold to customize the silver S925 pipe material, to a certain extent, avoid the waste of silver S925 material, and finally solve the problem for customers.

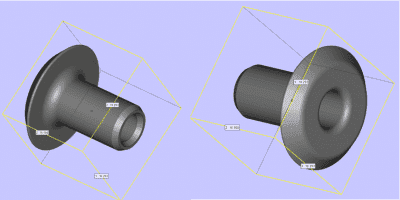

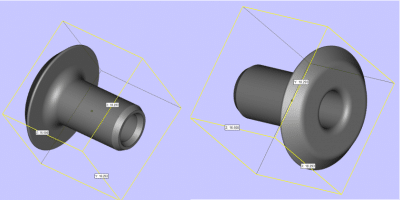

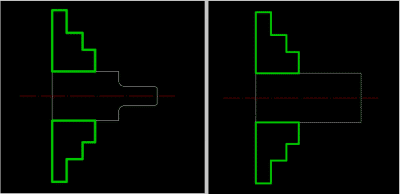

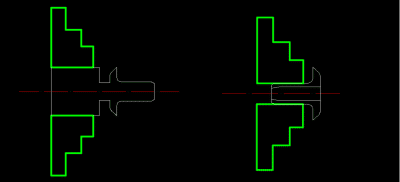

The silver parts processing technology is as follows:

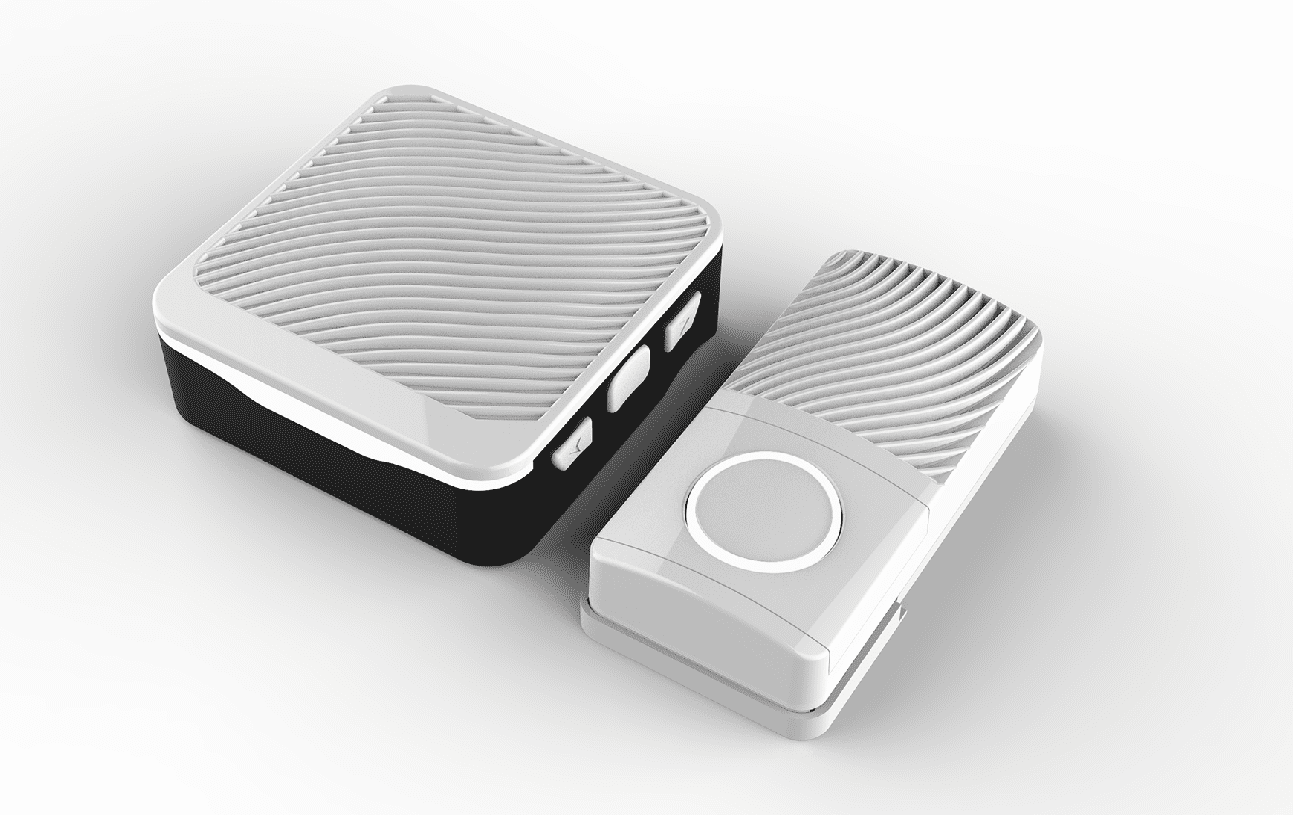

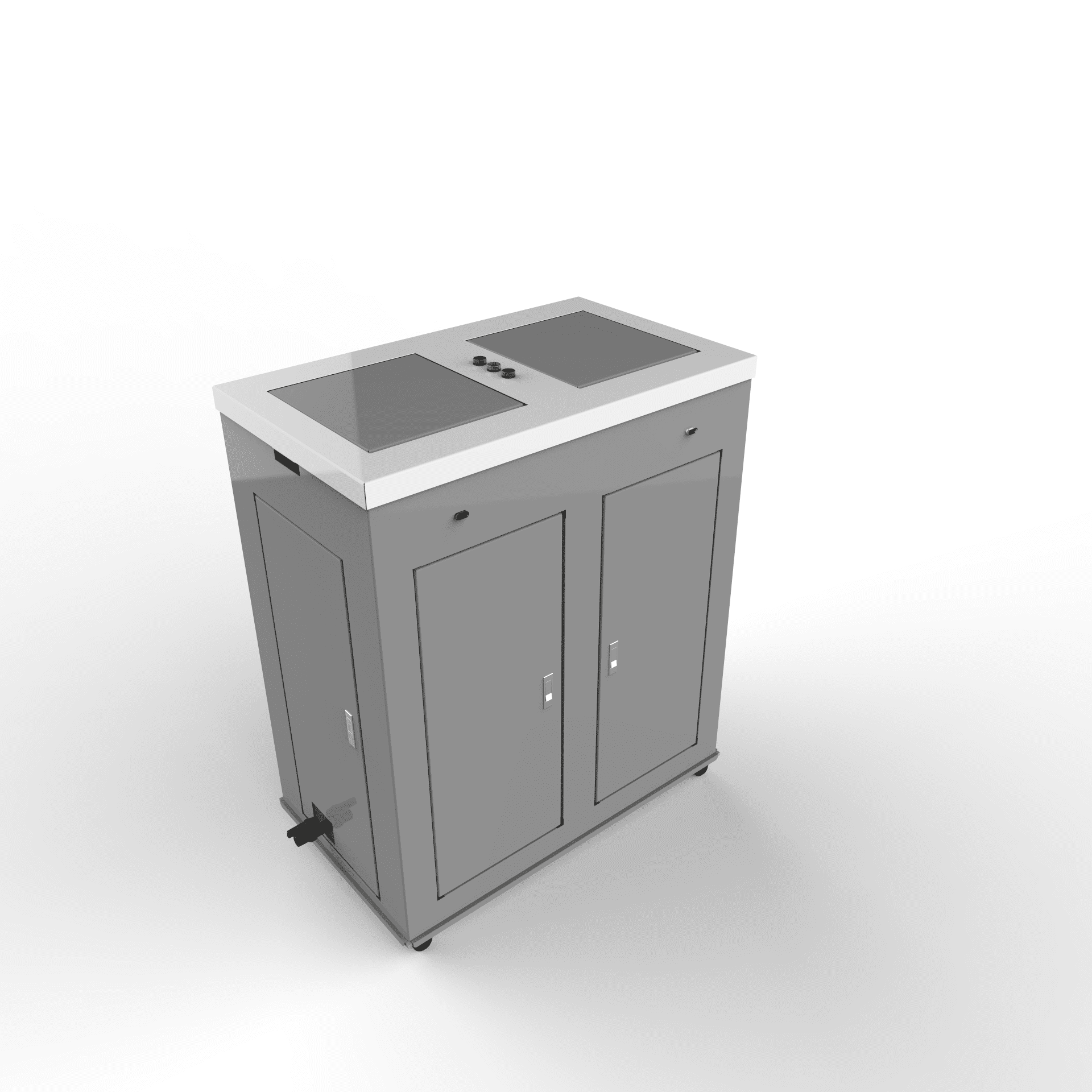

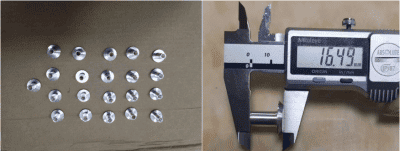

The silver parts finished picture:

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569