The rising consumer demands, the high demand rate, and sophisticated designs give birth to a new way to manufacture and machine the machining parts.

While CNC machines are precise in manufacturing CNC Crystal Laser Cutter to machine a wide variety of materials, they cannot manufacture products with sophisticated designs and shapes.

In this article, we’ll learn What is CNC Laser Cutting? How it Works, Types of Laser Cutting Machines, and If CNC Laser Cutting Suitable for my project? So, without any ado, let’s explore CNC laser-cutting near me.

What is CNC Laser Cutting?

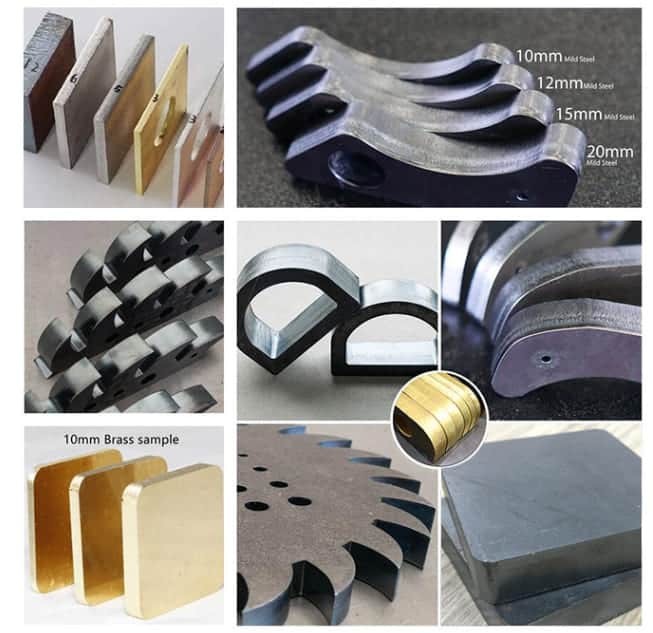

CNC Laser cutting uses a laser beam to melt, vaporize and carve the material to manufacture the shapes, holes, and designs.

For the parts with intricate designs and shapes, CNC laser cutting is the most effective method to manufacture them aesthetically appealing.

Like CNC machines, CNC cutting machines also depend on computer numerical control and commands, often known as G-code.

How Does CNC Laser Cutting Work?

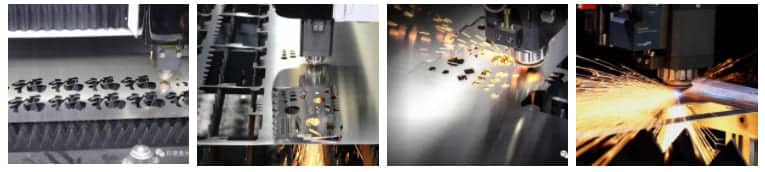

CNC laser cutting uses compressed gas to reduce the high temperature of the focusing lens. The focusing lens consists of a laser head.

And the lens focuses with the help of a nozzle. Once the lens and head concentrate on the material, they melt the fabric and cut the piece into the desired shape, design, and form.

Once focus on the laser beam, which has high power at a single point on a metal surface, the heat density becomes so high that can easily cut, mold, and engrave the shapes, marks, and holes according to the specifications.

Types of Lasers

- CO2 lasers are perfect for engravings and industrial use. And the laser has a high amount of power used for industrial applications such as cutting and welding.

- YAG is fantastic to use for metal marking and etching.

- Fiber lasers are cost-effective and versatile to use in cutting many different materials.

- Electrically exciting lasers use for precision sheet metal machining.

Types of CNC Laser Cutters

Like CNC machine types, CNC laser cutters also differ based on the active laser medium and its components. Most commonly, there are three types of CNC laser cutters such as:

1. CNC Fiber Laser Cutter

CNC fiber laser cutter is a recently invented laser cutting technology. It uses a bank of diodes to form a beam. A CNC fiber laser cutter focuses the beam through a fiber-optic cable.

If we want to enjoy a cleaner, faster, and highly precise cutting operation, then CNC fiber laser cutting is the best decision.

It is recommended to use fiber laser cutting where the material thickness is less than 5mm.

2. CNC CO2 Laser Cutter

It is a gas type that uses carbon dioxide as an active laser medium. If we want a highly refined product, engraving, and output, then a CNC CO2 laser cutter can be the best bet.

3. CNC Crystal Laser Cutter

We can use the CNC Crystal Laser Cutter to machine a wide variety of materials, such as glass, wood, plastics, and metals.

If CNC Laser Cutting Services Suitable for My Project?

Precision laser cutting is a reliable, faster, and highly cost-effective method to manufacture subtle designs and new products in bulk. Some of the benefits of selecting CNC laser cutting services are given below:

- CNC laser is more accurate, precise, and highly sophisticated. We can design the holes and designs even 2mm small.

- Unlike conventional CNC machining, CNC laser cutting doesn’t need any extra tools while machining any material. Likewise, we don’t need any additional devices such as CNC routers and CNC milling machines.

- Steel laser cutting saves big bucks by removing any need for post-processing. The cuts, marks, and engravings are highly precise and subtle for the design of the parts.

- Using the CNC laser cutting machine gives you faster processing and production.

- Precision sheet metal fabrication gives you even greater accuracy than Flame and Plasma cutting.

3 Things to Consider Before Selecting A CNC Laser Cutting Company

1. What’s Your Business?

Understand if you want to create highly sophisticated and aesthetically appealing products.

If your project wants a highly precise and accurate product, go for high-power CNC laser cutting services.

2. What’s Your Budget?

Budget is the main point whenever you want to select a CNC laser cutting service. Make sure we choose the sheet metal products which come under our expected price.

Many parameters decide the price of sheet metal products, such as cutting power and precision. More importantly, you’ve to face more expenses in case of any discrepancy and malfunctioning of the metal laser cutting machine.

3. Quality of CNC Laser Cutting Machines

Getting premium quality at the lowest price is not a sane option. So, whenever we want to choose a precision laser cutting machine go for the highest or at least suitable price possible. In this way, we can ensure the high-quality manufacturing of machining parts.

Conclusion

There can be flaws in intricate designs made by CNC machines; however, engravings, marks, holes, and sophisticated designs made from precision laser cutting machines are precise, perfect, and highly accurate.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569