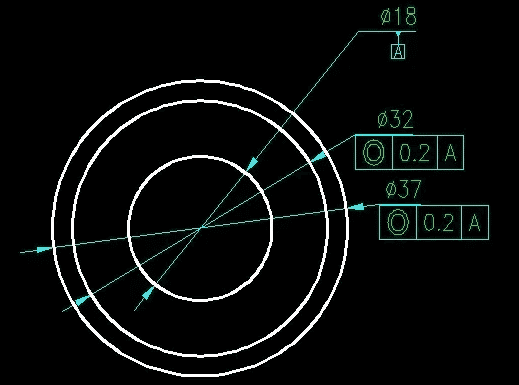

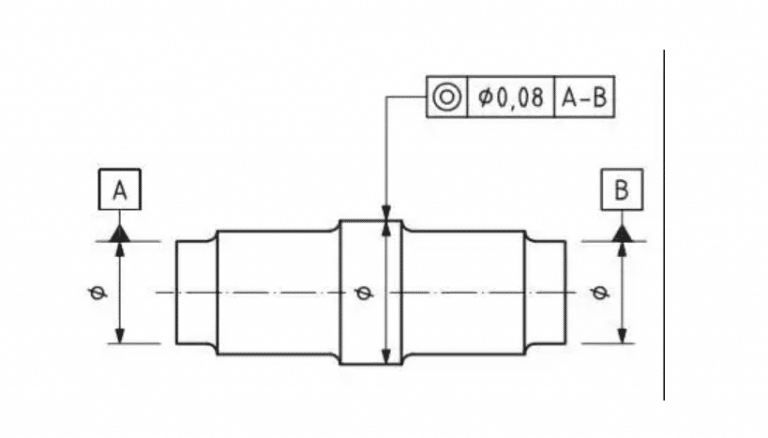

Concentricity is an important factor in the manufacturing process and quality control of cylindrical parts.

It measures how closely the central axis of a cylinder or other round object corresponds to its geometric center. In other words, concentricity measures how well-centered an object is.

There are a number of reasons why concentricity is important.

- First, when two or more cylindrical parts are assembled together, they need to be properly aligned in order for the assembly to function correctly. If the parts are not concentric with each other, it can cause problems such as misalignment, binding, or even breakage.

- Second, even if two parts are properly aligned, if they are not concentric, it can cause problems with the finished product. For example, if two parts are not concentric when welded together, the weld joint will be weaker and more likely to fail.

- Third, concentricity is also important for aesthetic reasons. Aesthetics are important in many industries, such as the automotive industry, where a vehicle’s appearance is very important to consumers. If parts are not concentric, it can make a vehicle look unappealing, leading to lost sales.

Benefits of Concentricity

Concentricity is an important mechanical property that affects the performance of many components and products.

It measures how well the different parts of a cylindrical object are aligned with each other and is usually expressed as a percentage.

The higher the concentricity, the better aligned the different parts are.

There are numerous benefits to having high concentricity in components and products.

For example, it can reduce wear and tear, improve dimensional stability, and increase strength and stiffness.

Improving concentricity can be challenging, but several methods can be used to achieve it.

Some common methods include jigs and fixtures, special tooling, and advanced machining techniques.

It is important to note that not all products need perfect concentricity.

Some applications that benefit from high concentricity include:

- Pipe fittings

- Hose couplings

- Electrical connectors

- Gear shafts

- Bushing sleeves

Many other applications can benefit from improved concentricity, so it is important to consult with an engineer or designer to determine if it is necessary for a particular application.

Concentricity is an important mechanical property that can affect the performance of many components and products.

It measures how well the different parts of a cylindrical object are aligned with each other and is usually expressed as a percentage.

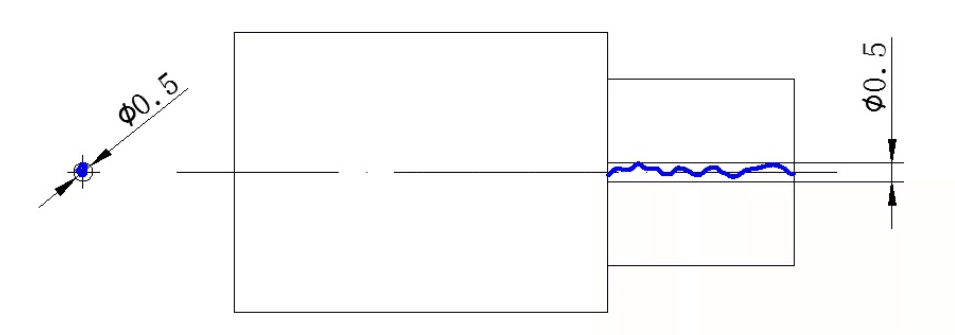

How to Measure Concentricity

It involves measuring how different parts of a cylindrical object deviate from a reference line.

It is important to use precision measurement tools and follow proper procedures to ensure accurate results.

Risks of Not Measuring Concentricity

If concentricity is not measured during the design and manufacturing process, it can lead to several problems.

For example, misaligned parts can cause increased wear and tear, premature failure, and reduced performance. In addition, it can make products difficult to assemble or use and can cause aesthetic issues.

It is important to measure concentricity during the design and manufacturing process to avoid these problems.

This will ensure that components and products meet the required tolerances and perform as intended.

There are many different ways to measure concentricity, so it is important to consult with an engineer or designer to determine the best method for a particular application.

How to Improve Concentricity?

Several methods can be used to improve concentricity. Some common methods include jigs and fixtures, special tooling, and advanced machining techniques.

In many cases, it is sufficient to have tolerances within an acceptable range.

If you are interested in learning more about concentricity and how it affects the manufacturing process, several resources are available online and in print.

Several software programs can help with the measurement and analysis of concentricity.

Key Takeaways

- Concentricity is an important factor in the manufacturing process and quality control of cylindrical parts.

- It measures how closely the central axis or other round object corresponds to its geometric center.

- In other words, concentricity is a measure of how well-centered an object is.

Why is Concentricity Important?

First, when two or more cylindrical parts are assembled, they need to be properly aligned for the assembly to function correctly.

If the parts are not concentric with each other, it can cause problems such as misalignment, binding, or even breakage.

Second, even if two parts are properly aligned, if they are not concentric, it can cause problems with the finished product.

For example, if two parts are not concentric when welded together, the weld joint will be weaker and more likely to fail.

Third, concentricity is also important for aesthetic reasons. Aesthetics are important in many industries, such as the automotive, where a vehicle’s appearance is significant to consumers.

If parts are not concentric, it can make a vehicle look unappealing, leading to lost sales.

Conclusion

No matter what industry you’re in, it’s important to be aware of concentricity’s role in manufacturing.

If you are having problems with the concentricity of your parts, take action and correct the issue as soon as possible.

Thank you for reading.

Recommended: 2023 Top 10 CNC Design Services Companies In China

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569