Are you tired of hearing that CNC parts are too expensive? If you’re involved in the manufacturing or engineering industry, you’ve likely encountered this.

But before you jump to conclusions, have you ever wondered what goes into the cost of these vital components?

In this blog post, we’re going to take a thorough analysis of the factors behind the cost of CNC parts.

From the machines and materials to the skilled labor and design, we’ll break down the reasons CNC parts are costly.

So, you’ll better understand the true value of CNC parts and the ways to optimize your manufacturing process to get the most bang for your buck.

Let’s debunk the myth that CNC parts are overpriced and explore the real factors driving their cost.

Are CNC Parts Expensive?

CNC parts can be high-priced because of their precision and complexity. But technology and outsourcing have made them more affordable.

They may cost more initially, but they often provide long-term savings with higher quality and durability.

Labor to Design Any Necessary Fixtures

Fixtures are custom-made tools that are used to hold the workpiece in place during the CNC machining process.

They ensure the workpiece remains in a fixed position and orientation, allowing for precise and accurate cuts.

The design of these fixtures requires skilled labor and can be time-consuming, adding to the cost of CNC parts.

Labor to Program Parts

The CNC machine needs specific instructions to create the desired part. The instructions are in a computer program that tells the machine what and how to do, and what tools to use.

Developing programs for CNC machines is an intricate and specialized process. It demands the expertise of skilled professionals.

The expenses incurred in hiring such skilled labor to create these programs further contribute to the overall cost of CNC parts.

Cost of Machine Time

The cost of running a CNC machine for a specific time includes expenses like electricity, tooling, maintenance, and labor costs.

Higher machine time costs mean higher production costs. It can happen due to high electricity consumption, longer running times, frequent tooling changes, or expensive tooling.

Cost of Tool Wear

When CNC machines make things, the tools that cut and shape the material become worn out after a while and need to be swapped with new ones.

It happens a lot when making very precise parts, requiring the tools to be changed more often. The cost of replacing these worn-out tools can be quite expensive.

Cost of Raw Materials

The cost of raw materials required for creating objects using CNC machines, such as metal or plastic, makes up a significant part of the expenses for the finished products.

Market fluctuations can cause the price of these materials to vary.

Also, the quality of the raw materials can impact the final cost of the product.

Labor to Supervise Machine During Run Time

When using CNC machines to make parts, keeping a close eye on the process is vital to ensure everything is being made to the right standards.

It means someone needs to be there to watch over the machine and ensure everything is going as planned.

Having an operator to supervise the process adds to the labor cost of making CNC parts.

Labor to Extract Part, Clean up the Machine, Finish Part, Inspect Part, Package, and Ship

Once the CNC machine makes the parts, they need to be taken out of the machine, cleaned up, checked for quality, and packaged carefully before shipping.

These steps all need skilled workers who know what they’re doing and can do the work properly.

These extra steps that need skilled workers can also raise the overall cost of CNC parts.

Profit and Overhead

Profit is the money the business makes after all the expenses, and overhead includes the costs of running the business.

These costs are necessary for the businesses to keep going and have to be included in the total of making CNC parts.

Why Is CNC So Expensive?

CNC (Computer Numerical Control) is a way of making things using computer-controlled machines.

These machines make very complicated parts with great accuracy. But, using them can be quite costly because many factors can raise the process price. Let’s see what they are:

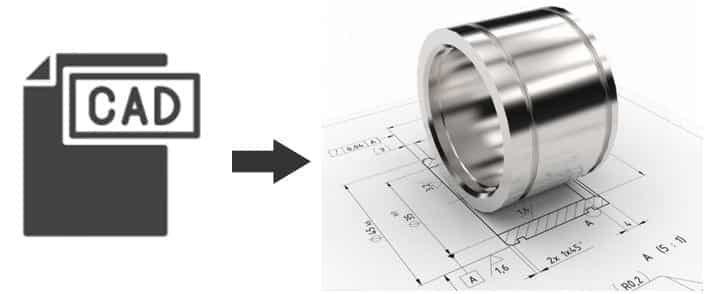

Machined Parts Design Cost

The cost of using CNC machines to make parts depends a lot on how those parts are designed.

If the part has a complicated shape or needs to be precise, it takes longer and is harder to make. That means it costs more money to manufacture those parts.

Recommended: Top 10 CNC Design Services Companies In China

Drawing Design

To make a machine part, you need to draw a detailed design or computer model of the part first.

It takes a lot of time and skill to do correctly, and it costs money to pay for the people who can do it.

All these things add to the cost of making the part using a fancy computer machine.

Recommended: Machined Parts Design Services

Mold Design

When making a part using CNC machining, sometimes a special tool called a mold is needed.

However, creating this mold can be exorbitant because it requires a lot of design and manufacturing work.

It will then add the cost of making the mold to the overall cost of the CNC machining process.

The more complicated the mold is, and the more cavities it needs, the more pricey it will be.

Programming and Setup Time

Before a machine can make a part, someone needs to tell it what to do. For CNC machines, this means programming the machine to make the part you want.

This specialized task takes a lot of time and skill. Once the machine is programmed, it still needs to be set up and adjusted before it can start making the part.

These steps can raise the price of CNC machining.

Material

The kind of material that’s used to make a part can affect how much it costs to use a CNC Machine.

Certain materials like titanium or Inconel are harder to cut, which means the people using the machine need special tools and methods. It makes the whole process more expensive.

Tools

Special tools for designing and cutting materials can be pricey, especially if you have to work with hard materials or complex shapes.

As a result, the cost of these tools can add up and increase the overall expense of the machining process.

QA

Quality assurance is like checking your work after completing a task to ensure it’s done right.

It is vital to examine and assess the CNC components to ensure their compliance with the specified criteria. But this extra step also means it costs more to make the parts.

How to Make CNC Parts Cheaper?

CNC machining can be quite pricey, but there are some tricks to make it cheaper while still keeping the things made with it high-quality.

Simplify the Design

When making parts using CNC machines, the more complicated the design of the part is, the more it will cost to make.

But, if you simplify the design, it can be made faster and with fewer tools, making it affordable.

Optimize Material Selection

Picking the right stuff can make CNC making cheaper. Choosing a material that costs less or is simpler to cut can save time and resources, making the process economical.

Use Standard Tooling

Using commonly available tools is cheaper and easier than creating tools specifically for a particular job.

If parts are designed to work with these standard tools, it can greatly reduce the cost of creating those parts.

Optimize Cutting Parameters

You can enhance the efficiency of your machines and extend the longevity of your tools by modifying the way you cut materials.

You can achieve this by optimizing the speed, depth, and force of the cutting process.

By implementing these adjustments, you can also reduce the expenses involved in producing CNC parts.

Consider Outsourcing

Outsourcing CNC machining means hiring another company to make the parts instead of doing it yourself.

This can make it cheaper to make the parts. The other company might be good at making the parts and can do it faster and cheaper than you can.

How Much Does it Cost to CNC Parts?

It’s not easy to figure out how much it costs to make parts with a CNC machine. A bunch of things can affect the price, like how hard it is to make the part, what stuff is used to make it, how many parts you need, and how long it takes to make them. And if you want something special or extra done, that can cost more.

Typically, when you use CNC machining to make something, there are two main things you need to pay for.

First, you pay for the machine, which costs between $10 to $30 per hour or more.

Second, you need to pay for the material to make your thing, which can cost anywhere from $100 to a few thousand dollars.

To find out how much it will cost you to make your thing, you just need to add those two costs together.

Also, keep in mind that the place you go to get your thing made can affect how much you will need to pay.

Conclusion

CNC parts are undoubtedly costly, but their importance and necessity cannot be overlooked.

The high cost of CNC parts is due to various factors, including the complexity of the design, the quality of materials, the precision required, and labor costs.

Additionally, transportation and storage costs also add to the final price of CNC parts.

But, the benefits of CNC parts are many, especially in industries where precision and accuracy are paramount, including aerospace, automotive, and medical devices.

Compared to manual manufacturing processes, CNC parts offer unmatched precision and consistency.

So, their high cost is justified by the level of skill, technology, and materials required to produce them.

To sum it up, CNC parts may be expensive, but their value far outweighs the cost.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569