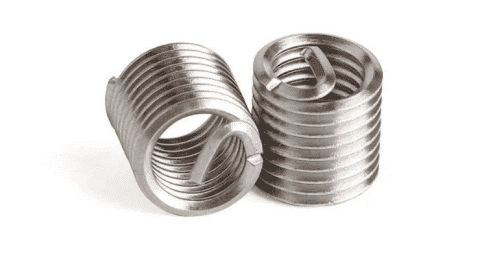

What is Threaded Insert?

The threaded insert is made of high-quality stainless steel wire with a diamond-shaped cross-section and is mechanically rolled into a spring-shaped thread.

The diameter of the ordinary threaded insert is larger than the diameter of the inner threaded hole.

When installing the threaded insert, the threaded sleeve will gradually be compressed and tightened to fit the installation hole.

After the installation is completed, the elasticity of the threaded insert will cause the threaded insert to rebound.

The expansion force is formed to achieve permanent fixation of the threaded hole. Because the diameter of the threaded insert is larger, the contact surface of the threaded insert is larger, which is stronger than the original thread in quality and effect.

The Roles of Screw Threaded Insert

First of all, the connected parts can be used to enhance the connection strength, improve the connection conditions, and obtain better connection performance.

Wire thread inserts are made of low-strength materials such as aluminum and magnesium, which can avoid slippage and misalignment, to obtain better-tightening performance.

Improve the wear resistance of the connected parts. For example, applying the thread insert to the parts that are frequently disassembled can greatly improve the service life of the thread.

Threaded inserts can be used for parts that need to increase the force-bearing area when the load-bearing requirement becomes larger or the connection strength is required to be larger, but the diameter of the screw hole cannot be directly increased.

The threaded insert has a very good anti-loosening performance. Especially in the occasions where products such as aerospace vehicles have very high requirements on the insurance factor, the technology of screw-threaded inserts has been applied for the first time.

Threaded inserts feature ease of maintenance. We can install the damaged internal thread screw hole into the wire screw threaded insert, to obtain a good thread environment, and after the repair, it has a stronger tightening performance and can continue to use the original screw hole, which can well avoid thread damage and the possibility of scrapping of the entire parts.

Although we may not be familiar with threaded inserts the threaded insert has been widely used in automobile maintenance, aviation, aerospace, machinery, construction, furniture, and other industries.

Generally speaking, the assembly tools of screw-threaded inserts include taps, screw taps, plug gauges, wrench installation, sleeve removal, and punching.

The installation and use steps include drilling, tapping, installation, and horizontal line cutting.

Mastering the functional principle of the thread insert in detail can make better use of the thread insert and provide more convenience for our production work.

Self-Tapping Screw Thread Insert Commonly Used Materials

Carbon steel: Suitable for aluminum alloy, copper alloy, plastic, and other engineering strength is low on the substrate.

Stainless Steel 303: Suitable for cast iron and other high-strength materials.

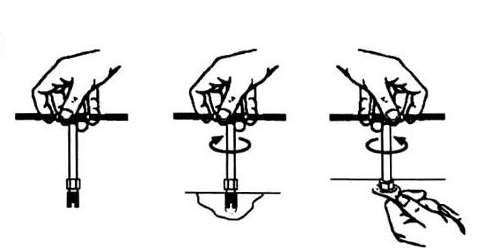

Installation Method

- Open the hole. According to the workpiece material, select the drilling diameter range. Please refer to the following comparison table.

- The slotted end or the three-hole end is down, and the self-tapping screw sleeve is installed at the front end of the tool, vertically against the workpiece, turn the alarm hand, and transfer it into the bottom hole.

- After inserting it into the specified position, use the clamping plate to fix the hexagonal part of the tool, and then reverse the plate handle to separate the tool from the workpiece.

Commonly Used Thread Insertion Specifications

Model 302 (slotted) self-tapping screw sleeve. The head of the screw sleeve has a cutting groove, with high-strength wear resistance thread, the cutting groove has self-tapping characteristics, is easy to transfer, highly seismic anti-loosening performance.

Suitable for: light alloy, cast iron, nonferrous metal, fiber-containing plastic, resin, and hardwood.

|

specifications

|

Internal screw thread

|

External screw thread

|

length

|

Reference bore diameter |

Minimum borehole depth

|

||

| plastic | Aluminum alloy | Cast iron | |||||

| M2.5*M4.5*6 | M2.5-0.45 | M4.5-0.5 | 6 | 4.0-4.1 | 4.1-4.2 | 4.2-4.3 | 8 |

| M3*M5*6 | M3-0.5 | M5-0.5 | 6 | 4.5-4.6 | 4.6-4.7 | 4.7-4.8 | 8 |

| M3.5*M6*8 | M3.5-0.6 | M6-0.75 | 8 | 5.3-5.4 | 5.5-5.6 | 5.6-5.7 | 10 |

| M4*M6.5*8 | M4-0.7 | M6.5-0.75 | 8 | 5.8-5.9 | 6.0~6.1 | 6.1-6.2 | 10 |

| M5*M8*10 | M5-0.8 | M8-1.0 | 10 | 7.1-7.2 | 7.3-7.5 | 7.5-7.6 | 12 |

| M6*M9*12 | M6-1.0 | M9-1.0 | 12 | 8.1-8.2 | 8.3-8.5 | 8.5-8.6 | 15 |

| M6*M10*14 | M6-1.0 | MIO-1.5 | 14 | 9.0-9.2 | 9.2-9.3 | 9.3-9.4 | 17 |

| M8*M12*15 | M8-1.25 | M12-1.5 | 15 | 10.6-10.8 | 11.0-11.2 | 11.2-11.4 | 18 |

| M10*M14*18 | MIO-1.5 | M14-1.5 | 18 | 12.6-12.8 | 13.0-13.3 | 13.2-13.4 | 22 |

| M12*M16*22 | M12-1.75 | M16-1.5 | 22 | 14.6-16.8 | 15.0-15.3 | 15.2-15.4 | 26 |

| M14*M18*24 | M14-2.0 | M18-1.5 | 24 | 16.6-16.8 | 17.0-17.3 | 17.2-17.5 | 28 |

| M16*M20*22 | M16-2.0 | M20-1.5 | 22 | 18.6-18.8 | 19.0-19.3 | 19.2-19.5 | 27 |

Thank you for reading.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569