What is Computer-Aided Manufacturing?

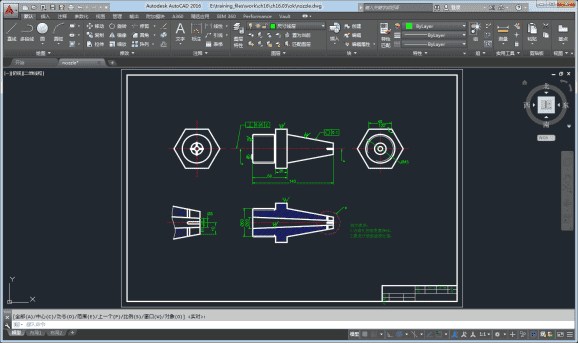

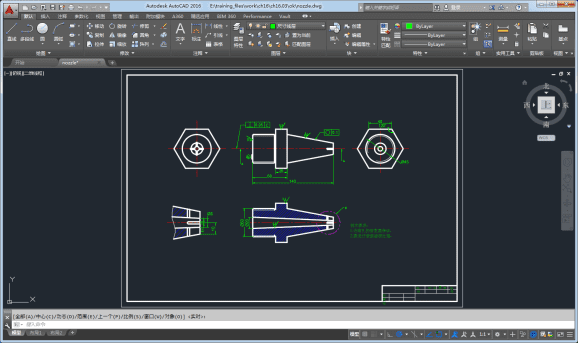

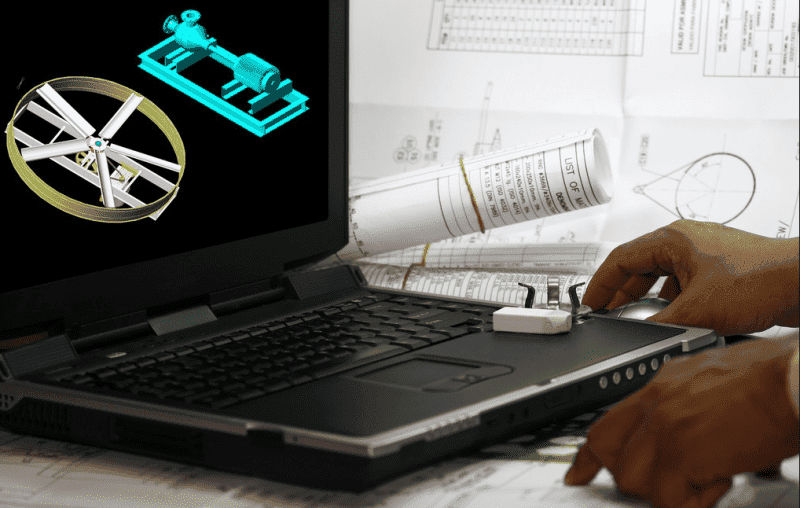

PC Aided Manufacturing (CAM) alludes to a computerization interaction that precisely changes over item plan and drawing of any article into a code design, discernible by the machine to make the item. The framework permits experts who have finished Computer-Aided Design courses to control apparatus in an exceptionally robotized climate to fabricate different things and pieces.

CAM is likewise utilized in all PC-helped activities in an assembling plant, like preparation, the executives, happening, and capacity.

A CAM device uses a product design developed in CAD software. The previous converts the computer system versions right into a language understood by the machining device as well as carries out the production. CAM can also aid producers with product planning, growth, administration, storage space as well as logistics.

The primary purpose of CAM is to either develop brand-new or surpass existing manufacturing configurations to improve efficiency and minimize waste. It does so by accelerating the manufacturing procedure and also tooling, as well as reducing power needs. The final results have a high level of consistency, top quality, and also precision.

Production Processes Automated by CAM

We can control a selection of procedures with CAM systems. These processes are performed by means of a CNC machine (Computer system Numerical Control). This equipment follows their provided G codes as well as M codes to equip a workpiece. CAM can automate compliance with processes.

Waterjet, Laser, and Also Plasma Cutting

CNC can automate the various kinds of cutting machines to sculpt work surfaces with incredible accuracy. They can likewise etch workpieces as and also when needed. Plasma cutting is useful for conductive materials such as steel.

Electrical Discharge Machines

Electrical discharge equipment produces components by circulating an electrical spark with them. These stimulate reach extreme heat enabling them to cut through any product quite quickly. With CAM, we can control these stimulates to cut the workpiece with a high degree of precision.

CNC Routers

CNC routers utilize comparable working reasoning to milling machines, removing excess material from a workpiece. They can perform a range of woodworking procedures on numerous materials such as wood, compounds, steel, glass as well as plastic through CNC.

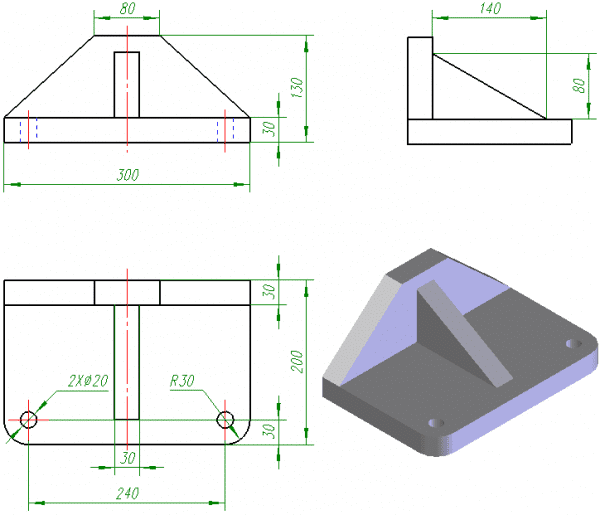

Milling

CAM can automate the milling of workpieces in applications where there is a demand for subtractive production. Via CAM, the machinists can accurately get rid of excess product from workpiece blocks. Making use of CAM with CNC machining allows making use of the information for quick quotes on machining work.

Turning

The turning process eliminates excess material from a workpiece by revolving it against the device. CNC turret devices are very efficient when producing the ideal order of treatment for creating the final product. These makers are likewise capable of various other processes such as carving threads, knurling, chamfering, dealing with, and so on.

3D Printing

CAM can also control additive manufacturing procedures such as 3D printing effectively. With this procedure, CAM can manufacture essentially any type of form by depositing layer upon layer of compatible products until the wanted shape is ready.

Advantages of Computer-Aided Production

Rapid As Well As Accurate

Computer-aided production can significantly accelerate the manufacturing procedure. All this without jeopardizing accuracy. This makes CAM highly consistent as well as dependable. CAM devices can be set to create the exact same product continuously with unparalleled accuracy. Single prototype production is exact and fast also.

Decreases Wastage

CAM usage reduces the amount of wastefulness that typically occurs in hands-on machining. Because there is a small chance of mistakes, a higher number of items are made from the same quantity of raw material. This sort of increased efficiency builds up gradually. The manufacturer can now either increase his revenue or established competitive prices or even do both.

Reduced Work Costs

CAM can conserve work costs by automating the majority of the manufacturing process. Proficient labor will still be required to run, preserve, and repair web cam makers yet the number of workers will be far less than without CAM. Another reason for lowered work costs is the versatility of the CAM machine. These pieces of equipment are compatible with several manufacturing procedures removing the demand for specialized work when switching over production procedures.

Enhanced Control Over Production

The introduction of CAM in a factory enhances the amount of control the manufacturer has over the entire procedure. Via a feature called the camera tree, a production procedure can be tracked from start to end. It offers the maker control over numerous features such as supply, tooling, product, work coordinates, and also post-processing. CAM can additionally conserve machining design templates for future use, reorder job sequences, and also copy/paste machining operations.

Any type of adjustments in the part can be carried out conveniently without the requirement to reprogram equipment. Toolpath associativity makes certain that when such adjustments are made, the toolpaths get upgraded.

Downsides of Computer-Aided Production

Price

One of the key deterrents, when it concerns cam systems, is the high expense of setup as well as upkeep. The hardware is pricey therefore is the software program, making the upfront costs high. CAM uses highly advanced elements that are costlier than their manual equivalents.

They likewise set you back more in regards to computer processing power, preventative maintenance, and also failure repair of CAM devices. Such a massive installment can be a difficulty for little configurations.

However, many camera software programs have actually now begun adopting a subscription-based version rather than a one-time purchase. This has actually minimized the advance costs and lowered the access obstacle, therefore.

Knowledgeable Work

CAM devices have a large extent. They are hard to find out for new users. Computer-aided production setups call for experienced workers with a mutual understanding of the CAM systems available. The systems can differ from firm to company as well as the employees need to be taught the use and also abilities of the regional system. They may additionally need training on just how to troubleshoot problems in CAM machinery.

This training might require consistent updates as systems gain brand-new features and also capacities. This sort of training and practice is expensive as well as might place a burden on the center.

Technology Failing

While the possibilities are reduced, computer errors are possible. An additional opportunity is the breakdown of CAM makers. CAM jobs can stop extremely conveniently if the makers break down as there might be no alternatives to begin hands-on production.

This is specifically damaging in assembly line arrangements as CAM work stoppage at one workstation can create halts in any way and various other factors until the problem is remedied.

Waste

While the effective use of CAM can significantly decrease wastage, it does not ensure minimal leftovers. A great deal of it comes down to product layout. If the product models are not ideal, it might in fact cause the waste of expensive resources. By the time it becomes apparent, it might be too late, specifically when it comes to materials that can not be reused such as styrofoam, ceramic, and also some kinds of plastics. Disposal or recycling of waste items will call for additional time and resources.

Computer-Aided Production Applications in Industries

CAM finds use in many various sectors that it’s most likely easier to call the ones that do not use it. The intro of IT, electronic devices, and computer-based automation processes was the beginning of the 3rd industrial transformation. Due to its extraordinary advantages, mathematical control quickly took over production. Let’s take a look at several of the sectors that CAM changed entirely.

Aerospace Industry

This sector is associated with the layout, manufacture, screening, as well as maintenance of aircraft that might fly within or even outside the planet’s environment. There are several dangers in this market to human life as well as building, and hence, it is extremely managed.

Aircraft need accurate components that perform as made. They likewise need to pass numerous examinations. This needs consistency and also high quality in aircraft parts. Consequently, hand-operated machining does not provide up-to-par outcomes.

Many free-form surface areas with complex geometries are a demand for visual and useful reasons. Quite often, these parts will be made from unusual products that have qualities really vary from everyday design steels. Computer-aided production gives excellent service for all the above difficulties. Its flexibility, accuracy, as well as speed, help us develop these works of art while remaining within budget.

Automotive Market

The automotive industry today is the most advanced as well as requires a market second only to the aerospace sector. Rigorous laws regulate the vehicle sector likewise from security to contamination. The manufacturers maintain to try out new products, designs and approaches to acquire the most effective worth for money.

Computer-aided manufacturing has actually been verified extremely helpful for makers right from the concept phase to the launch phase.

CAM can make innovative items armed with functions such as tool-axis meanings, appearing, as well as a polygon mesh. Camera software can supply a collection of concentrated toolpaths as well as modeling choices to develop complex forms within brief periods of time while totally integrating them with principles such as lean production and also Just-in-Time manufacturing.

Computer-aided manufacturing can substantially minimize expense, wastage, lead times, as well as errors. It boosts precision, surface coating, consistency, as well as production rate. These attributes make CAM a vital part of the automobile market.

Various other industries

Besides the instances above, the camera locates lots of applications in industries such as computer and smartphone equipment production, biomedical devices, the pharmaceutical industry, and more. Basically, most all modern-day mass production arrangements apply computer-aided production to increase performance.

As the camera automates basically all the primary procedures currently, there is little possibility of any type of huge-scale production while staying clear of the computerized nature of modern manufacturing innovation.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569