Galvanization is a process in which metal is coated with zinc to protect it from corrosion. The process of galvanizing metal has been around for centuries, but it wasn’t until the 19th century that the technique was perfected and widely used.

Today, galvanized metal can be found in many common everyday objects, from automobiles to home appliances. But what exactly is galvanized metal? And what types of galvanized metals are there?

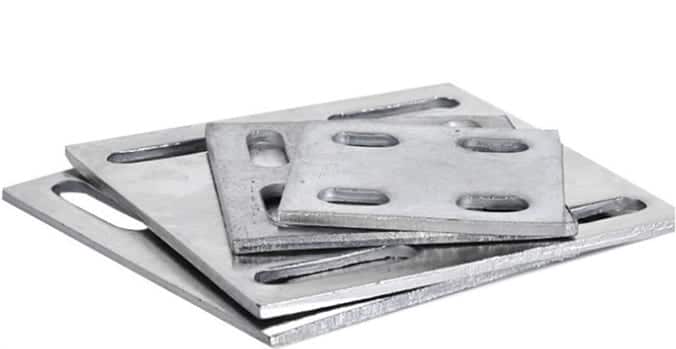

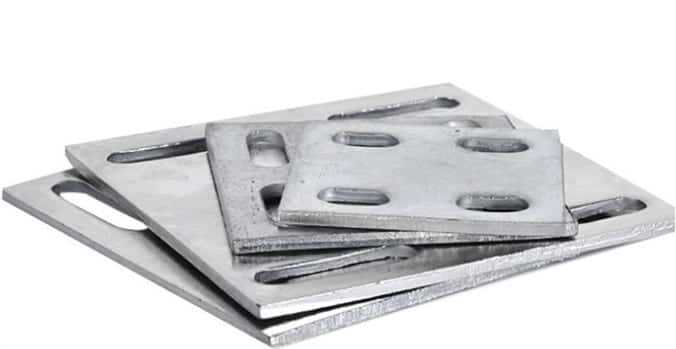

What Is Galvanized Steel?

Galvanized steel is a type of steel that has been coated with a layer of zinc. This coating serves two purposes: it helps prevent corrosion of the underlying steel and provides an aesthetically pleasing finish.

The zinc coating also provides additional strength to the steel, making it more durable than regular steel.

Galvanization processes typically involve two steps: first, a special electroplating process is used to deposit a thin layer of zinc onto the surface of the steel; then, any exposed areas are treated with zinc paint or powder to provide added protection against corrosion.

The following are the properties of Galvanized Metal:

Corrosion and Rust Resistance

One of the key properties of galvanized metal is its resistance to corrosion and rust. This resistance is due to the layer of zinc that is applied to the surface of the metal during the galvanization process.

The zinc reacts with the surface of the metal, forming a layer of zinc-iron alloys that protect the underlying metal from corrosion and rust. This protection is important for outdoor applications where the metal is exposed to the elements.

Durability

Galvanized metal is also known for its durability. The layer of zinc that is applied to the surface of the metal during the galvanization process provides a strong and durable barrier against the damaging effects of exposure to the elements.

This makes galvanized metal an ideal choice for use in harsh outdoor environments where other materials may deteriorate quickly.

Low Cost

Galvanized metal is also relatively low cost compared to other materials, making it an attractive option for cost-conscious consumers and businesses.

This low cost is due to the fact that galvanized metal is made from readily available materials, such as steel or iron, and the galvanization process is relatively simple and efficient.

Formability

Another property of galvanized metal is its formability. Galvanized metal can be easily shaped and molded into a wide range of shapes and sizes, making it an ideal choice for use in a variety of applications.

This formability makes galvanized metal a versatile material that can be used in many different ways, from building and construction to agriculture and livestock, transportation and automotive, and marine.

Easy to Clean and Maintain

Galvanized metal is also easy to clean and maintain. The smooth surface of the metal makes it easy to wipe down or wash, and the resistance to corrosion and rust ensures that the metal will look like new for many years.

This makes galvanized metal an attractive choice for applications where appearance is important, such as in the building and construction industry.

What Are The Different Types Of Galvanized Metals?

There are several different types of galvanized metal available on the market today, each designed for specific applications depending on the desired result and budget. Here are just some of the most common types:

Hot Dip Galvanizing

Hot dip galvanizing is one of the oldest methods for protecting steel from corrosion. It involves immersing clean steel in a bath of molten zinc at temperatures up to 500 degrees Celsius.

The zinc reacts with the iron in the steel to form an alloy layer known as “zinc ferrite,” which provides an extremely strong bond between the two metals that prevents oxidation and other corrosive elements from damaging it further.

Electro-Galvanizing

Electro-galvanizing is another popular method for galvanizing metal that involves electroplating it with a thin layer of zinc through an electrolytic process.

This type of galvanization produces a thinner coating than hot dip galvanizing but still offers adequate protection against environmental factors that could lead to corrosion or rusting over time.

Mechanical Plating

Mechanical plating is another method used to protect the metal from oxidation and environmental exposure.

In this process, small particles of zinc are deposited onto the surface using mechanical force rather than chemical solutions like those used in electroplating or hot dip galvanizing processes.

While not as durable or long-lasting as other types, mechanical plating can provide adequate protection for short-term applications such as parts assembly or repairs where additional strength isn’t required.

Galvalume Steel

Galvalume steel is a type of coated steel sheet composed of aluminum, silicon alloyed with aluminum, and zinc alloyed with aluminum that undergoes a hot dip process resulting in an extremely durable protective finish that can withstand harsh weather conditions without flaking or losing its structural integrity over time.

Metal Spraying

Metal spraying is yet another form of metal protection where molten zinc particles are sprayed onto the surface using high-pressure equipment, ensuring superior coverage and protection even in small crevices and tight areas where a manual application would be difficult to achieve by hand.

Galvanization Process – All Steps Explained

Galvanization is a process that helps protect steel, iron, and other metals from corrosion. It involves coating the metal with zinc to protect it from rust and other types of damage.

The galvanization process can be used for a wide range of products, from car parts to construction materials. Let’s take a closer look at the galvanization process and how it works.

Step 1: Cleaning the Metal

The first step in the galvanization process is to thoroughly clean the metal that needs to be coated. This involves removing any dirt, grease, or other contaminants that could interfere with the coating process.

Depending on what type of metal is being coated, various cleaning techniques might be used, such as hot alkaline cleaning solutions or abrasive blasting.

Step 2: Applying a Pre-treatment Coating

Once the metal is clean, it is then pre-treated with an anti-corrosive solution before being coated with zinc. This helps ensure that any remaining contaminants are removed so they won’t interfere with the galvanizing process.

The pre-treatment also helps improve adhesion between the zinc and metal surfaces which increases the longevity of the coating.

Step 3: Applying Zinc Coating

The next step in the galvanizing process is to apply a thin layer of zinc onto the surface of the metal.

This can be done either by dipping or spraying on a liquid zinc solution or by electroplating (a technique where an electrical current is used to deposit a layer of zinc). Once applied, this layer will help protect against corrosion for many years to come.

Step 4: Inspecting and Testing

After all, steps have been completed, it’s important to inspect and test the galvanized material to make sure everything was done correctly, and there are no defects in either its appearance or performance.

If necessary, adjustments can be made at this point before allowing it into circulation or use in manufacturing processes.

6 Benefits of Galvanized Metal

This process has many benefits, making it popular among manufacturers who use metals in their products. Here are 6 key advantages of galvanizing metals that everyone should know about.

Increased Longevity

By protecting the surface of the metal, galvanizing can significantly increase its lifespan. Zinc is highly resistant to corrosion, so it provides an effective barrier against rust and other types of degradation that can weaken or destroy metal components over time.

This makes galvanized metals an excellent choice for products that need to withstand harsh environments or long-term use.

Improved Safety

Galvanized metals are also safer than non-coated alternatives because they don’t corrode as easily. This prevents them from releasing hazardous chemicals into the environment, which could be harmful to humans and animals alike.

Additionally, since they don’t corrode as easily, they’re less likely to break down or become structurally unsound over time—making them a safer choice for any product or structure that needs to be extra durable.

Cost Effectiveness

Galvanizing is a relatively cost-effective process compared to other options, such as painting or powder coating.

Since zinc is relatively inexpensive compared to other materials used in coatings (like paint or aluminum), it’s cheaper for manufacturers to use it for protection against corrosion and wear and tear.

Additionally, since galvanized metals last longer than non-galvanized materials do, manufacturers don’t have to replace them as often—saving money in the long run.

Aesthetic Appeal

Galvanized metals can also look great when properly applied! The zinc coating gives off a reflective shine that adds visual appeal and makes products stand out from the crowd—perfect for those looking for an attractive finish on their parts or structures without having to resort to expensive painting processes.

Eco-Friendly

Since galvanizing doesn’t require additional chemicals as some coatings do, it’s better for the environment overall.

It uses fewer resources during production and releases fewer toxins into the atmosphere—making it an eco-friendly way to protect your metal components from corrosion and wear and tear over time.

Enhanced Durability

Galvanization creates a protective barrier that prevents corrosion and rusting, greatly increasing the life expectancy of metals. This coating also protects against environmental elements like moisture, dust, dirt, and chemicals.

You can expect metal surfaces treated with galvanization to last up to four times longer than untreated metal surfaces exposed to similar conditions.

Applications and Uses of Galvanized Metal

The galvanized metal is strong, durable, and highly resistant to corrosion and rust, making it ideal for use in a wide range of applications.

Building and Construction

One of the most common uses of galvanized metal is in the building and construction industry.

Galvanized steel is often used in the construction of commercial and residential buildings, as well as in the manufacturing of various building components such as roofing, wall panels, and gutters.

The resistance to corrosion and rust makes galvanized steel a popular choice for outdoor applications where it is exposed to the elements.

Additionally, galvanized steel is relatively low cost compared to other building materials, making it an attractive option for cost-conscious builders and contractors.

Agriculture and Livestock

Galvanized metal is also widely used in the agriculture and livestock industries. Galvanized steel is commonly used in the construction of livestock pens, feed bins, and barns, as it is durable and resistant to corrosion and rust.

Galvanized metal is also used in the manufacture of various agricultural equipment, such as irrigation systems, farm machinery, and grain silos. The resistance to corrosion and rust ensures that these products will last for many years, even in harsh outdoor environments.

Transportation and Automotive

Galvanized metal is also used in the transportation and automotive industries. Galvanized steel is commonly used in the construction of automobiles, trucks, and buses, as it is strong and durable.

Additionally, galvanized metal is used in the manufacturing of various automotive components, such as exhaust systems, fuel tanks, and body panels.

The resistance to corrosion and rust makes galvanized steel an ideal choice for these applications, as it will protect these components from the damaging effects of exposure to the elements.

Marine

Galvanized metal is also used in the marine industry, as it is resistant to corrosion and rust, making it ideal for use in harsh outdoor environments.

Galvanized steel is often used in the construction of boats, docks, and other marine structures, as well as in the manufacturing of various marine equipment, such as life rafts, mooring chains, and anchors.

The durability and resistance to corrosion and rust make galvanized metal an excellent choice for use in the marine industry.

Conclusion

Whether you’re working on a residential construction project or an industrial manufacturing project, there are numerous advantages gained by choosing to use galvanized metals rather than untreated ones.

Galvanization adds longevity by protecting against corrosion while providing improved aesthetics compared to other options on the market today – all while remaining eco-friendly.

Plus, with reduced maintenance costs associated with using these materials over time, it could be the perfect choice for your next project.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569