Anodized aluminum stands as a testament to the fusion of science and aesthetics. Through an electrochemical process, this versatile material undergoes anodization, resulting in a protective oxide layer that not only fortifies its surface but also unlocks a spectrum of design possibilities.

In this exploration, we delve into the unique properties of anodized aluminum and the pivotal role design plays in bringing out its visual brilliance.

Brief Explanation of Anodized Aluminum and Its Unique Properties

Anodized aluminum, derived from pure aluminum, undergoes a transformative procedure called anodization. This process entails immersing the aluminum in an electrolytic solution and applying an electric current.

Consequently, a controlled oxidation process takes place, creating a resilient, corrosion-resistant, and visually appealing oxide layer on the metal’s surface.

Enhanced Durability:

Anodized aluminum stands out for its heightened durability, attributed to the protective oxide layer that functions as a formidable shield.

This layer serves as a robust defense mechanism, safeguarding the metal against corrosion, abrasion, and wear.

This exceptional durability renders anodized aluminum an optimal selection for an array of applications, ranging from architectural features to industrial components.

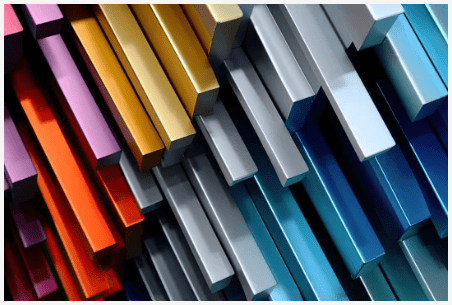

Color Variety:

Anodized aluminum is celebrated for its vibrant color options. Unlike traditional coatings, the color in anodized aluminum is not applied but is a result of interference with light during the anodization process.

This characteristic ensures that the color is integral to the material, providing longevity and resistance to fading.

Eco-Friendly Characteristics:

The anodization process is environmentally friendly, producing no harmful by-products. This aligns with the growing emphasis on sustainable and green design practices, making anodized aluminum an appealing choice for those conscious of its environmental impact.

The Significance of Design in Anodized Aluminum Products

Design isn’t merely an aesthetic consideration but a fundamental aspect that amplifies the inherent beauty of anodized aluminum.

The material’s properties offer a canvas for creativity, enabling designers to shape products that captivate the eye and stand the test of time.

Texture and Patterns:

The unique surface of anodized aluminum allows for the incorporation of various textures and patterns. Whether it’s a sleek, smooth finish or a textured surface that adds depth and character, designers can play with these elements to evoke specific emotions or convey a particular aesthetic.

Architectural Integration:

Anodized aluminum finds its place as a design element in architecture, seamlessly blending functionality with elegance. From striking façades to intricate interior details, the material’s malleability and range of finishes make it a preferred choice for architects seeking both durability and design flexibility.

Customization and Personalization:

Designers can leverage the customization options of anodized aluminum to create unique and personalized products. The ability to incorporate logos, graphics, or specific color schemes allows for the tailoring of products to meet the distinct preferences of clients or end-users.

Overview of the Anodization Process and Its Impact on Design

Anodization Process:

Anodization is a controlled electrochemical process that enhances the properties of aluminum. The aluminum is immersed in an electrolytic bath and subjected to an electric current.

This results in the formation of a protective oxide layer on the surface, altering the material’s characteristics. Beyond the practical benefits of increased durability and corrosion resistance, the anodization process is the gateway to unlocking design potential.

Impact on Design:

The anodization process fundamentally alters the surface of aluminum, allowing for a myriad of design possibilities. Designers can manipulate color, texture, and finish, creating products that not only withstand the test of time but also captivate with their visual appeal.

This transformative process turns anodized aluminum into a blank canvas upon which design brilliance can unfold.

Different Types of Anodized Aluminum Finishes and Their Visual Effects

Clear Anodized Finish:

Clear anodized aluminum maintains the natural appearance of the metal while adding a layer of protection. This finish is ideal for applications where the original aluminum color is desired, offering a sleek and modern aesthetic.

Colored Anodized Finish:

Colored anodized finishes open a spectrum of possibilities. Through a controlled oxide layer thickness, a range of colors can be achieved, providing designers with the flexibility to match specific color schemes or evoke certain moods.

Textured and Matte Finishes:

Textured and matte finishes introduce tactile elements to anodized aluminum. From smooth, satin-like surfaces to textured patterns, these finishes enhance both the visual and tactile experience of products, adding depth and sophistication.

Case Studies – Innovative Design Choices with Anodized Aluminum

Case Study: The Luminous Facade of Aurora Towers

Project Overview: Aurora Towers

Aurora Towers, an architectural marvel standing tall in the heart of the city, showcases the seamless integration of anodized aluminum, redefining the skyline with its striking presence.

The use of anodized aluminum in this iconic building not only contributes to its aesthetic appeal but also plays a pivotal role in enhancing its structural integrity.

Architectural Vision:

Aurora Towers was conceived as a symbol of modernity and innovation, blending form and function. The architects envisioned a structure that not only captivates with its visual allure but also stands as a testament to sustainable design practices.

Anodized Aluminum Integration:

The choice of anodized aluminum was integral to realizing the architectural vision. The entire facade of Aurora Towers is enveloped in custom-designed anodized aluminum panels, providing a sleek and durable exterior.

The anodized finish not only enhances the aesthetic appeal but also ensures long-lasting resistance against environmental factors.

Dynamic Color Palette:

Aurora Towers showcases the versatility of anodized aluminum with a dynamic color palette. The exterior panels transition through a spectrum of hues, creating a mesmerizing visual effect throughout the day.

The anodized finish not only provides vibrant colors but also introduces a subtle sheen that adds depth to the facade.

Day-Night Transformation:

As the sun traverses the sky, the anodized aluminum facade responds dynamically to changing light conditions. During the day, the building glows in natural light, and as night falls, carefully placed artificial lighting accentuates the anodized finish, turning Aurora Towers into a beacon of elegance.

Durability Beyond Beauty:

The anodized aluminum panels serve a dual purpose by contributing to the structural integrity of Aurora Towers. The material’s inherent durability ensures the facade withstands harsh weather conditions, including rain, wind, and UV exposure, maintaining its pristine appearance over time.

Lightweight and Sustainable:

Anodized aluminum’s lightweight nature played a crucial role in the overall sustainability of the project. Its reduced weight lessened the environmental impact during construction and facilitated easier installation, aligning with the eco-friendly ethos of modern architecture.

Conclusion: Anodized Aluminum in the Urban Tapestry

Aurora Towers stands as a testament to the transformative potential of anodized aluminum in architecture. Its captivating facade, adorned with anodized aluminum panels, not only elevates the city’s skyline but also showcases the material’s ability to seamlessly blend aesthetic appeal with structural resilience.

Case Study: QuantumEdge Laptop Series

Product Overview: QuantumEdge Laptop Series

The QuantumEdge Laptop Series exemplifies the convergence of aesthetics and technology, pushing the boundaries of high-tech design.

This case study delves into how anodized aluminum is seamlessly integrated into these cutting-edge electronic devices, showcasing adaptability, durability, and a futuristic design language.

Visionary Design Concept:

The QuantumEdge Laptop Series was conceived with a vision to redefine the laptop experience. A key aspect of this vision was to create a device that not only boasted state-of-the-art technology but also stood out in terms of design, blending seamlessly with the modern lifestyle.

Anodized Aluminum Integration:

Anodized aluminum became the material of choice for the laptop’s exterior casing. This integration went beyond mere aesthetics; it was a deliberate choice to enhance the device’s durability, dissipate heat efficiently, and provide a premium tactile experience for users.

Sleek Anodized Finish:

The QuantumEdge Laptop Series boasts a sleek anodized aluminum finish, giving it a premium and modern look. The anodized surface not only provides a refined aesthetic but also contributes to the laptop’s resistance against scratches and fingerprints, ensuring it maintains its pristine appearance.

Precision Machining:

The precision machining of the anodized aluminum casing allows for a seamless design, eliminating unnecessary joints and presenting a unibody structure. This not only enhances the laptop’s visual appeal but also reinforces its structural integrity, providing a robust frame for the cutting-edge technology within.

Technological Integration:

Heat Dissipation and Cooling:

Anodized aluminum’s excellent thermal conductivity is harnessed to enhance the laptop’s cooling system. The casing efficiently dissipates heat, ensuring optimal performance even during resource-intensive tasks.

This integration not only contributes to the laptop’s functionality but also extends its lifespan.

Lightweight and Portable:

The lightweight nature of anodized aluminum contributes to the overall portability of the QuantumEdge laptops. Users can enjoy high-performance computing power in a device that is sleek, durable, and easy to carry, thanks to the material’s strength-to-weight ratio.

User Experience:

Tactile Elegance:

Anodized aluminum provides a tactile elegance, creating a premium user experience. The laptop’s exterior feels cool to the touch, and the anodized finish adds a layer of sophistication to the device, elevating it beyond the ordinary.

Customization Options:

Users have the option to personalize their QuantumEdge laptop with different anodized finishes, allowing them to express their individuality. This customization feature adds a touch of exclusivity to the device, making it more than just a tool but a reflection of the user’s style.

Conclusion: The Fusion of Form and Technology

The QuantumEdge Laptop Series demonstrates that anodized aluminum is not merely a choice of material but a strategic design element in the realm of cutting-edge electronics.

Its seamless integration into the laptops not only enhances their visual appeal but also contributes to their functionality and user experience.

In this case study, anodized aluminum emerges not just as a casing material but as a pivotal component in the fusion of form and technology, marking a new era in high-tech device design.

Case Study: LuminaCraft – Bespoke Furniture Design

Project Overview: LuminaCraft Bespoke Furniture Collection

LuminaCraft, a bespoke design studio known for pushing the boundaries of creativity, embarked on a unique journey to redefine furniture aesthetics.

This case study explores how LuminaCraft leveraged the unique properties of anodized aluminum to craft one-of-a-kind pieces, showcasing the versatility, durability, and elegance of this remarkable material.

Design Philosophy:

LuminaCraft’s design philosophy revolves around creating furniture that not only serves a functional purpose but also serves as a statement piece in any space.

The team sought to showcase the potential of anodized aluminum in crafting bespoke furniture that seamlessly marries form and function.

Anodized Aluminum as a Canvas:

Anodized aluminum was chosen as the primary material for the bespoke furniture collection. The studio recognized that the material’s unique properties, including color versatility and durability, could elevate each piece into a work of art.

Aesthetic Excellence:

Dynamic Color Palette:

The bespoke furniture collection features a dynamic color palette made possible by custom anodized finishes. From rich metallic hues to subtle pastels, each piece tells a story through its color, allowing clients to tailor their furniture to match their personal style and the ambiance of their living spaces.

Textured Surfaces and Patterns:

LuminaCraft experimented with various anodized aluminum textures and patterns, adding depth and dimension to the furniture pieces. From sleek, brushed surfaces to intricate patterns created through anodization, each piece became a tactile experience, inviting touch and admiration.

Functional Elegance: Crafting with Anodized Aluminum

Lightweight and Sturdy Construction:

Anodized aluminum’s lightweight nature plays a crucial role in crafting furniture that seamlessly blends elegance with functionality. The pieces are not only visually striking but also easy to move and rearrange, offering flexibility in interior design.

Customized Design Solutions:

LuminaCraft collaborated closely with clients to understand their preferences and needs. The result was a series of customized furniture solutions, including chairs, tables, and shelving units, each uniquely tailored to complement the client’s lifestyle and existing decor.

Showcasing Innovation: Iconic Furniture Pieces

Anodized Aluminum Accent Chairs:

One standout piece from the collection is the “LuminaLounger,” an accent chair featuring a sleek anodized aluminum frame. The chair not only provides a comfortable seating experience but also serves as a visual focal point in any room, thanks to its custom anodized finish.

Dynamic Dining Table:

The bespoke dining table is a testament to the studio’s innovation. The anodized aluminum tabletop boasts a mesmerizing pattern achieved through anodization, turning a functional piece into a sculptural centerpiece for family gatherings.

Conclusion: Crafting Stories with Anodized Aluminum

LuminaCraft’s bespoke furniture collection showcases the transformative power of anodized aluminum in the realm of design. Through careful exploration of finishes, textures, and personalized design, each piece tells a unique story.

Design Trends in Anodized Aluminum

Current Trends in Anodized Aluminum Design for Various Industries

Architectural:

Anodized aluminum has become the material of choice in contemporary architecture. The trend leans towards sleek, minimalist designs, with architects utilizing anodized aluminum’s malleability to create captivating facades and structural elements.

Aerospace:

In the aerospace industry, anodized aluminum is taking flight in both form and function. Designers are embracing lightweight anodized components that not only contribute to fuel efficiency but also showcase a shift towards futuristic, aerodynamic designs.

High-Tech Electronics:

The integration of anodized aluminum into high-tech electronic devices is on the rise. From smartphones to laptops, the trend is towards seamless, unibody designs that not only enhance aesthetics but also leverage anodized aluminum’s thermal properties for improved performance.

Exploration of Popular Color Palettes and Textures

Vibrant Color Schemes:

Contemporary design trends in anodized aluminum embrace vibrant and dynamic color schemes. From bold metallic tones to soft pastels, designers are leveraging the anodization process to create eye-catching finishes that resonate with the modern consumer.

Textural Diversity:

Textures play a pivotal role in anodized aluminum design. Smooth, brushed, or textured surfaces are used strategically to add depth and character. The trend is towards experimentation, with designers pushing the boundaries of what’s possible through the anodization process.

Naturalistic Finishes:

Emulating natural materials is a rising trend in anodized aluminum design. Woodgrain patterns and stone-like finishes are becoming popular choices, allowing for the creation of products that seamlessly blend into both natural and urban environments.

Incorporating Anodized Aluminum into Modern and Traditional Design Aesthetics

Modern Elegance:

In modern design aesthetics, anodized aluminum takes center stage. Sleek lines, minimalist forms, and monochromatic color schemes define this trend. The material’s reflective surface complements contemporary interiors and exteriors.

Traditional Fusion:

An exciting trend is the fusion of anodized aluminum with traditional design elements. Ornate patterns and intricate detailing on anodized surfaces are breathing new life into traditional architecture and furniture, creating a harmonious blend of old-world charm and modern resilience.

Customization for Individual Expression:

Designers are increasingly offering customization options, allowing individuals to express their unique style. Whether it’s a modern industrial look or a classic vintage feel, anodized aluminum is tailored to fit diverse design preferences.

Conclusion

The design landscape of anodized aluminum is a dynamic tapestry, woven with the threads of innovation and creativity. From architectural masterpieces to everyday consumer products, anodized aluminum continues to inspire designers to push boundaries and redefine what’s possible in the world of aesthetics.

As we navigate the ever-evolving design trends, anodized aluminum stands as a versatile medium, ready to shape tomorrow’s visual language.

If you need to get an anodizing advice, contact us anytime.

At Yijin Solution, we offer anodizing as a fundamental finishing option for metal components, complementing other techniques such as bead blasting, brushing, polishing, electroplating, powder coating, and painting.

Our proficient team possesses extensive expertise in the anodizing process, ensuring the delivery of premium-quality aluminum parts to our clients. If you are unsure whether anodizing is the optimal finishing solution for your specific part or product, feel free to reach out to a member of the Yijin Solution team for guidance.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569