Introduction

Identifying reliable partners in China’s saturated market challenges businesses outsourcing injection molding. The pressure to align with quality standards is overwhelming.

Also, choosing the wrong partner may lead to delays, quality issues, and increased costs. But fear not; discover top-tier injection molding companies committed to quality, innovation, and reliability.

Gain insights to choose partners exceeding expectations and explore how understanding the capabilities of these leading companies empowers businesses to make informed decisions.

Top 10 Injection Molding Companies In China

1. Yijin Solution

Shenzhen Yijin Hardware Co., Ltd. is your one-stop metal solution, offering diverse capabilities, precision focus, and material expertise. Specializing in Metal Injection Molding, CNC machining, casting, and more, they bring over a decade of experience and advanced equipment to deliver top-notch quality.

Key Strengths

- Diverse Capabilities: Handle various metalworking needs efficiently.

- Precision Focus: Deliver intricate parts with tight tolerances for demanding applications.

- Material Expertise: Work with ferrous and stainless steel options to meet specific requirements.

- Proven Track Record: Trusted supplier to renowned brands like Huawei, Xiaomi, and HP.

- Scalability: With 15+ production lines, NJCY efficiently handles high and low-volume orders.

Consider Shenzhen Yijin Hardware Co., Ltd. for your next metal project—a reliable partner dedicated to expertise and quality.

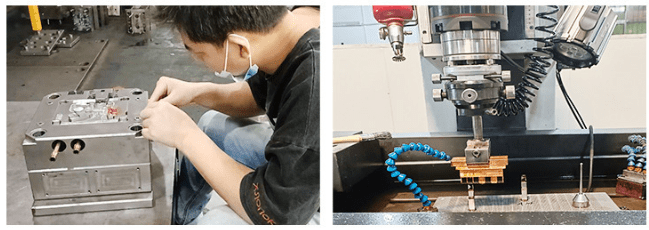

2. Forwa

Established in 2002, Forwa is another premier Chinese supplier specializing in plastic mold manufacturing and injection processing.

Precision Focus

Utilizing cutting-edge equipment like Makino CNC and Sodick EDM, Forwa’s mold department creates diverse molds, from injection to blow molding, weighing up to 15 tons.

Injection Excellence

Armed with Arburg, Nissei, and FANUC machines (30T to 380T), Forwa excels in delivering precise plastic parts for automotive, medical, and consumer electronics industries.

Gear Precision

Forwa excels in plastic gear manufacturing, achieving AGMA 7 class precision for smooth and quiet operation.

Transmission Expertise

The transmission department goes further, offering custom gearbox designs considering factors like noise, torque, and motor selection.

Progress-Oriented Culture

With 20 years of experience, Forwa prioritizes innovation and collaboration. A 20-person technical team, supported by 40+ injection machines and 60+ testing units, ensures project success.

Ready to collaborate with a trusted injection molding expert? Contact Forwa and unleash the potential of your plastic vision.

3. ZCMIM

ZCMIM, a premier Metal Injection Molding (MIM) expert in China, excels in crafting stainless steel components for electronics, medical, and automotive industries.

Diverse Materials

ZCMIM goes beyond standard metalwork, offering ferrous, tungsten, titanium alloys, and special materials for a perfect fit in your project.

Precision Manufacturing

Equipped with Japanese-imported furnaces and advanced machinery, ZCMIM’s factory produces over 100,000 high-precision pieces daily, ensuring top-notch quality.

Comprehensive Solutions

Beyond MIM, ZCMIM analyzes your needs and recommends the best solution, whether it’s MIM, CNC, Die Casting, or Stamping, ensuring both quality and speed.

Collaborative Support

From design to delivery, ZCMIM walks alongside clients, prioritizing communication and exceeding expectations in quality, turnaround time, and pricing.

Experienced and Certified

With 10+ years of expertise and ISO 9001:2015 certification, ZCMIM guarantees quality and customer satisfaction, boasting a proven track record in electronics, medical devices, and high-precision mechanics.

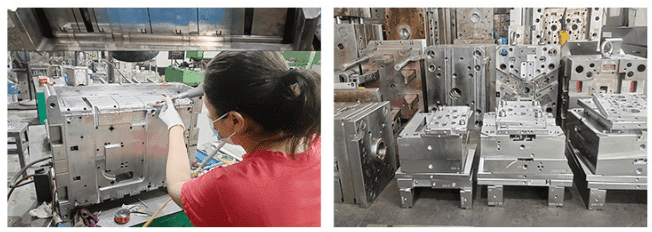

4. FOW Mould

FOW Mould, with 40 years of global experience, surpasses traditional mold making. As manufacturing partners, they bring plastic product visions to life, offering design assistance, prototyping, and material selection in one place.

Precision is paramount at FOW Mould, utilizing high-tolerance CNC machines and advanced injection molding equipment for exact specifications across various sectors, including automotive and baby products.

Recognizing the value of time, FOW Mould ensures rapid prototyping and fast turnaround times through an extensive network and scalable production capabilities.

Material mastery distinguishes FOW Mould. With access to diverse resins and alternatives, they find the ideal balance of performance and cost-effectiveness for each project.

They meticulously monitor every step, ensuring compliance with international standards. Their efficient processes and diverse material access maintain competitive costs. Serving various industries, they make parts for many sectors from automotive to home appliances.

For streamlined injection molding, reach out to FOW Mould for high-quality results and experience the difference of a genuine partner.

5. Ningbo Jiehuang Chiyang Electronic Technology Co., Ltd

Ningbo Jiehuang Chiyang Electronic Technology Co., Ltd. excels in CNC machining and injection molding, specializing in intricate medical, robust automotive, and sleek consumer electronic components.

Collaboration Matters

“Collaborate with Customers” isn’t just a slogan. Jiehuang Chiyang works closely with you, from design to material selection, ensuring your needs are met.

Trust in Quality

High-precision machinery and stringent quality control ensure durable, top-notch parts that meet the most demanding specifications.

Unleash Innovation

Jiehuang Chiyang offers a diverse range of materials and innovative technologies, tackling complex projects others might avoid.

Adaptable Scale

From mass production for global markets to smaller batches for niche projects, Jiehuang Chiyang caters to both large and low-volume orders with equal dedication.

Value-Driven

Competitive pricing and a focus on long-term relationships make Jiehuang Chiyang an attractive partner, striving for win-win collaborations.

Ready to Transform Ideas

Contact Jiehuang Chiyang to start a conversation. Their collaborative approach, commitment to quality, and diverse capabilities make them your perfect injection molding match.

6. CN-MIM

In metal injection molding (MIM), CN-MIM showcases unparalleled expertise, employing state-of-the-art techniques. Their proficiency lies in crafting intricate and high-performing metal parts at a scale that meets industry demands.

From design inception to the final product, their end-to-end process is marked by efficiency and a streamlined approach.

Breaking Boundaries

CN-MIM goes beyond traditional metalwork constraints, offering complex shapes and diverse materials like iron, steel, and stainless steel for demanding applications.

Perfectly Sized

Tailored for parts between 0.1 and 250 grams, CN-MIM specializes in intricate components, ideal for industries such as smartphones and wearable tech.

Cost-Effective Solutions

Optimal for production runs of 10,000 to 20,000, CN-MIM delivers cost-effective solutions with minimal material waste and nearly fully dense metal parts.

Expert Guidance

Unsure about MIM suitability? CN-MIM’s specialists consider design complexity, size, volume, and budget, guiding you through every step to find the perfect fit.

Unlock MIM Potential

Contact CN-MIM to explore the difference a trusted partner can make in realizing your project vision.

7. AT&M

Established in 1998, AT&M specializes in metallic materials and global solutions. Their Metal Injection Molding capabilities excel in producing high-precision, sub-100g metal parts for diverse applications.

MIM Mastery

With 32+ years of expertise, AT&M’s Metal Injection Molding process is ideal for cost-effective, high-volume manufacturing. They serve 3C Electronics, Medical, Automotive, and Green Edge industries.

Key Benefits

- High Precision: Parts meet exact specifications with tight tolerances (±0.3%).

- Complex Shapes: Achieve intricate geometries not possible with traditional methods.

- Diverse Materials: Choose from various metals to match project needs.

- Broad Applications: Customizable solutions cater to various industries.

- Sustainable Choice: AT&M’s eco-friendly Metal Injection Molding process minimizes waste.

Eager to leverage AT&M’s Metal Injection Molding expertise? Reach them out to discuss your project requirements.

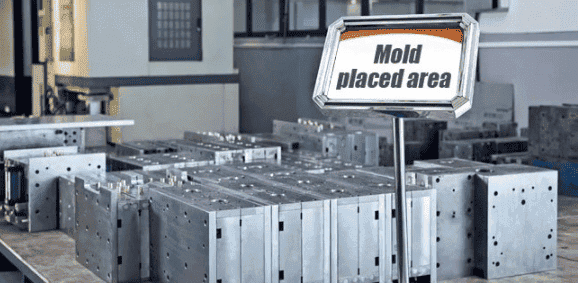

8. SOSITAR Mould

SOSITAR Mould: A Trusted Choice

With over 10 years in plastic injection molding, SOSITAR Mould boasts a global reputation, serving 200+ clients across 30 countries.

Based in Shenzhen, China, their 3,800 sqm facility is home to 150+ skilled toolmakers, producing 60-80 molds monthly, handling parts up to 1500g and molds up to 8.5m.

From design to quality control, SOSITAR is your one-stop solution, offering a comprehensive range of services.

Key Strengths

- Experienced Team: 150+ skilled toolmakers and professional engineers.

- Advanced Equipment: Swiss and Taiwanese technology for high-precision manufacturing.

- Comprehensive Services: Covering design, mold flow analysis, and project management.

- Quality Assurance: Adhering to strict ISO9001 standards for guaranteed quality.

- Global Clientele: Serving clients worldwide with proven success.

Choose SOSITAR Mould for a reliable plastic injection molding partner—dedicated to quality and customer satisfaction. Reach out today.

9. Xiamen Sunled

In metal manufacturing, Xiamen Sunled has been a key player since 2006. Now operating as Xiamen Sunled Metal Manufacturing Co., Ltd., this specialized entity thrives in metal injection molding (MIM).

Their expansive 50,000 sqm facility houses cutting-edge production lines for MIM, mold making, powder metallurgy, CNC machining, and more.

Expert in Metal Injection Molding, Sunled produces complex, near-fully dense metal parts with tight tolerances for demanding applications.

Select from diverse metal options to meet your project’s specific needs and ensure optimal functionality.

Adhering to ISO 9001 standards, Xiamen Sunled prioritizes quality from design to final inspection.

With a proven track record, Sunled has longstanding relationships with clients in the US and Europe, showcasing reliability and excellence.

Explore the benefits of Xiamen Sunled’s Metal Injection Molding expertise by reaching out to discuss your project needs.

10. GianMIM

GianMIM, a leading MIM manufacturer since 2006, partners with hundreds of global companies. Known for quality and service, they specialize in complex, high-precision metal parts.

Going beyond standard methods, GianMIM offers intricate ferrous-based and stainless steel parts with tight tolerances, complex shapes, and superior aesthetics.

Experts not just in design but also in various materials, including ceramics and titanium alloys, GianMIM ensures a perfect fit for your project’s needs.

A one-stop solution, GianMIM handles everything from design assistance to post-processing, streamlining your journey from concept to the finished product. They serve various industries like consumer electronics, medical, automotive, and more.

High precision is one of their main strengths, ideal for accuracy-demanding applications. They can create intricate geometries and offer diverse material options.

With fast turnaround times and a commitment to meeting your needs, GianMIM is ready to unlock the potential of MIM for your project.

Conclusion

China presents a vast landscape of injection molding companies, each with unique strengths and specialties. Whether you seek intricate metal parts or durable plastic components, navigating this diverse market can be overwhelming.

This guide has highlighted ten leading players, carefully curated to encompass various capabilities and expertise. From Yijin Solution’s collaborative approach to Forwa’s gear manufacturing and ZCMIM’s diverse materials, each showcased company offers distinct value propositions.

How to Choose the Best Partner for Your Injection Molding Project?

Keep in mind that finding the perfect partner depends on the specific needs of your project. Consider factors like:

- Project type: Are you working with metal or plastic? Do you require intricate geometries or high-volume production?

- Desired materials: Do you have specific material requirements for functionality or aesthetics?

- Budget and timeline: Do you have enough budget to beat the deadline?

- Reputation and experience: A proven track record and strong client relationships signal reliability.

Take advantage of this information to initiate targeted conversations with potential partners. You’ll find the perfect fit for your injection molding project in China by effectively communicating your needs and exploring their capabilities.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569