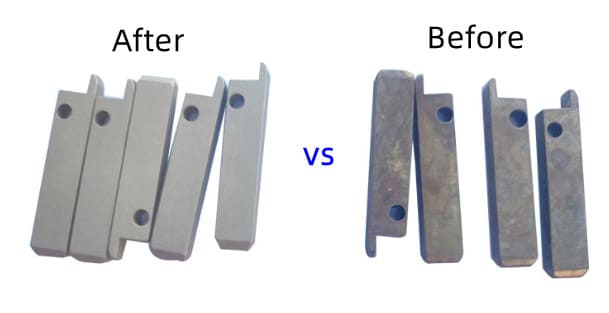

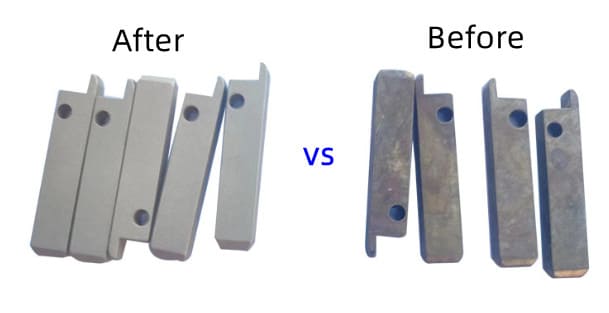

Bead blasting is a great way to give your parts a uniform, high-quality finish, but there are some points to bear in mind to ensure that you get the results you want. In this post, we’ll walk you through the process of achieving a perfect bead blast finish every time, from choosing the right media to controlling the blasting.

What Is It?

Bead blasting is a technique used to clean or roughen a surface by propelling tiny particles at it at high speeds. The beads can be made of glass, ceramic, or even plastic. Bead blasting is an efficient and speedy method of surface cleaning and painting prep. It’s feasible, requires little effort, and costs little.

How Does It Work?

Bead blasting propels small spheres or beads against a surface to roughen it. The resulting surface finish is called bead blast and is characterized by being more even than the original surface. This method is often used when a smooth, even finish is desired.

Bead blasting can create different textures on a material’s surface, from satin to dull. You can also use it to condition the tensile strength of a part. When choosing bead blasting as your preferred method, you can be sure that you’ll get consistent results every time.

[ux_video url=”https://youtu.be/FNPla4K1ZwI” depth=”2″]

Bead Blast Finishing Equipment

To get the best results from the bead blasting procedure, you must use the best tools. This section will tell you about the tools and materials needed for the Bead blasting process.

Bead Blaster Cabinets

You could have guessed from the name that this is exactly where the procedure starts. We insist on premium quality for this cabinet so that the whole process is successful. You should find some important things in better cabinets.

First, they need to be made of strong materials. In terms of its durability and resilience, steel is a fantastic material. It makes the tool last longer and is incredibly durable. Also, you don’t want a cabinet with legs that aren’t very firm. So, the cabinet should have nice, powerful, and sturdy legs welded to it.

The cabinet, the components to be blasted, and the bead media all have to fit on the legs. So, legs that aren’t steady will eventually shake. This is often dangerous for the person doing the work. It can also be annoying if the tool breaks while you’re working.

The following are some other important parts of a good cabinet:

Seamless Cabinet Sealing

It should be sealed properly on the inside. The best seals ensure that dust and other things inside the cabinet don’t get out. Dust and other waste from abrasive blasting can pose several health risks. Some serious injuries can happen if you breathe in dust or have something slippery on the floor.

View Window Protection

Most people need to notice the view window on the bead-blasting cabinet. Large windows will let you see what’s inside the cabinet well. The single most important consideration, however, is to keep the window safe. A few glass beads may prompt the glass to frost over time.

So, they make it hard to see, which is a big problem. So, it’s a good idea to have protective sheets that you can change on your windows to blast longer without problems.

Bead Blaster Gloves

When you are bead blasting, you should put safety and comfort first. This is where gloves for bead blasting come in handy. They help you give the cabinet a bead blast surface safely and comfortably.

Most of the time, these gloves come with the cabinet. Having these gloves would shield the hands from blasts. They also help you hold on to bead blaster guns well.

Bead Blaster Gun

The bead blaster gun is another important part of a bead blasting cabinet. Blasting can only happen with a blast gun. There are multiple gun designs, some of which are quite complex.

You can use a bead blaster gun with either a foot pedal or a pedal. The user decides which gun to use. But blast guns with foot pedals are often more relaxed for long blasting sessions. Long-term use of a trigger blast gun might be tiresome.

Glass Beads

The media, which are the glass beads, are the most important part of bead blasting. Glass beads are made from round pieces of lead-free soda-lime glass. The process of glass bead blasting is good for the environment as they are much softer as compared to other materials.

Benefits

There are several advantages to bead blasting:

- It’s a relatively fast process when compared to other finishing techniques.

- It produces a consistent finish with no visible brush lines.

- It’s gentle enough not to damage delicate surfaces.

- The finish is long-lasting and corrosion-resistant.

Things To Consider

The following are some considerations to think about while selecting a bead blaster:

- The size of the cabinet (you’ll want one that’s big enough to accommodate your largest projects)

- The type of blast nozzle ( there are several different nozzle types available, each with its advantages and disadvantages)

- The power source ( many bead blaster cabinets run on compressed air, but some models are electric)

Safety Precautions

Once you’ve selected a bead blaster cabinet, there are a few safety precautions you need to take before you begin:

- Wear protective clothing, gloves, goggles, and dust masks.

- Ensure the place you’re working in is ventilated perfectly.

- Before using this machine, please read the handbook thoroughly.

Applications

Bead blasting can help with various purposes, including Peening, Deburring, Cosmetic finishing, Removing paint, and more.

- Peening is a process where small beads are blasted at a metal surface to create small dimples.

- The term “deburring” refers to the practice of smoothing out a product’s rough spots. This is usually done with a handheld tool but can also be accomplished with bead blasting.

- Cosmetic finishing creates a smooth, glossy surface on a workpiece.

- Paint, calcium deposits, rust, and scale can all be removed with bead blasting. This is often done as preparation for powder coating or painting.

- Bead blasting can also polish materials like stainless steel, aluminum, and cast iron.

Automotive Parts

A popular option in the automotive industry is bead blast finish, which can add a sleek and stylish look to your vehicle. However, this finish type also requires special care when applying automotive components. Bead blasting uses tiny glass beads to create a textured surface, so you must be cautious not to scratch or chip the paint.

Weapons And Other Military Equipment

The bead blast finish is commonly used on firearms and other military components for various reasons. First, bead blasting provides a matte finish that helps to reduce glare and reflections. This is critical in combat situations, where even a brief reflection can give away a position.

Additionally, the bead-blasted surface is very smooth, which helps to prevent fouling and the buildup of debris. Finally, bead blasting can provide a degree of corrosion resistance, which is essential in harsh environments. For these reasons, bead blast finishes are an excellent choice for firearms and other military components.

Aluminum Materials In The Medical Industry

Aluminum is a popular material for making medical components, as it is strong yet lightweight. Bead blast finishes can help improve the durability of aluminum components and their aesthetic appeal.

In addition, bead blast finishes can also help to reduce the risk of infection by providing a smooth surface that is easy to clean. As a result, bead blast finishes are important to ensure that medical components are safe and effective.

How To Achieve A Superior Bead Blast Finish

Adjust The Pressure

The pressure at which you operate your bead blaster can also impact the quality of your finish. If the pressure is too high, the media will bounce off the surface and not remove all contaminants. The media will only remove all contaminants if the pressure is raised. Experimenting with different pressures is important to find what works best for you.

Prepare The Surface

Before you begin bead blasting, it’s important to prepare the surface that you’ll be working on. This means removing loose paint or debris for an even and smooth surface.

Begin Bead Blasting

Once everything is set up, you’re ready to begin bead blasting! Start by holding the nozzle about 6 inches from the surface and moving it back and forth until all the contaminants have been removed.

Inspect Your Work

After you have completed the bead blasting, step back and carefully examine the work that you have done. Make sure that all the contaminants have been removed and that no areas look uneven or unfinished. If everything looks good, you’re ready to move on!

To Sum It Up

You can use Bead blasting to give surfaces a matte finish and increase their resistance to wear and tear and corrosion. It’s important to adjust the pressure for optimal results and prepare the surface before beginning. With the right technique and preparation, bead blasting can make your work easy!

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569