As mentioned earlier, the fastener lockout is merely to delay the shedding of the bolt/nut to buy time for maintenance. So is there really no specific drug to prevent loss?

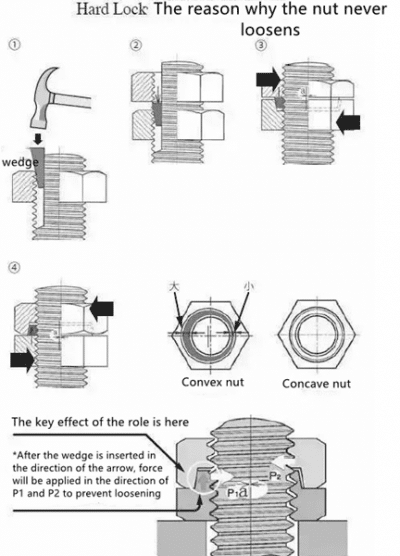

Japanese Hard lock nut anti-loosening principle: this nut is used in pairs, divided into the concave nut and convex nut, pay attention to the sequence of installation, convex nut in the lower part of the first, concave nut in the upper part of the rear. Convex nuts are manufactured by eccentric processing, concave nuts are normal center-round processing, when the two convex and concave nuts are screwed together, as if a wedge is inserted into the nut, thus achieving the effect of anti-loosening.

So far, Hard Lock nuts have been used in railways in Australia, Britain, Poland, China, and South Korea. Since the introduction of Hard Locknuts in Taiwan, there has been no personal accident record. In addition to railways, many countries and regions at home and abroad have adopted Hard Locknuts, such as the world’s longest suspension bridge Akashi Kaikyo Bridge in Japan, the world’s highest free-standing radio tower Tokyo Sky Tower, the U.S. space shuttle launch pad, and ocean drilling machine.

Principle of Chinese self-locking nut: using the helical surface match structure between nut and gasket, realize the application of self-tightening force theory, and with a specific lifting Angle, fully achieve the role of anti-loosening, so that it can only tighten can not loosen, and loosen the nut must be turned gasket to achieve.

Since China nut cutting helical surface of the end surface is designed to support the structure, not only increase the stability of connecting deputy, at the same time also completely stress after the termination of the nut is tightened mostly concentrated in the first, the lack of the traditional fasteners on the two teeth, so that the stress distribution, not only greatly improve the bearing capacity of the nut and screw, but also reduces the damage degree of the internal and external screw thread.

Doesn’t it look Aesthetic?

For the auto industry, however, that may not work, or at least it may be hard to promote.

Automobile manufacturing is a highly industrialized industry, which has high requirements for cost control, assembly efficiency, and after-sales maintenance.

Obviously, none of the above.

Yijin Hardware thought that the choice of anti-elastic firmware is similar to health. So-called “special effects” fasteners are more like “antibiotics” and should not be tried as a last resort. The only way is to build up resistance. How to enhance resistance? For connection design, ensure that sufficient residual clamping force is maintained in the connection.

Robust design is the real “effective” anti-loosening.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569