The screw is very widely used in daily life, almost everywhere, like fixing plates, making wood products, and so on. There are many types of screws, of which the two kinds of self-drilling screws and self-tapping screws are the most used by mechanical workers.

But beginners in the mechanical industry, sometimes confuse the difference between the two screws and think they are the same. What is the difference between self-drilling screws and self-tapping screws?

In this post, we will talk about the materials, types, and uses for self-tapping screws and self-drilling screws.

Self-Tapping Screw

A self-tapping screw is a kind of screw with sharp points, deep thread, and a large pitch. It can be drilled, tapped, fixed, and locked at one time through special electric tool construction.

The difference between self-tapping screws and ordinary screws is that ordinary screws must have processed screw holes before they can be screwed in. Self-tapping screws do not need to be tapped at the same time as they are screwed in.

Self-tapping screws can be made of soft materials, and rely on their own threads to “tap, drill, extrude, and press” the corresponding threads of the consolidated body to make them fit tightly. Self-tapping screws are mostly used for the connection between thin metal plates (steel plates, saw plates, etc.).

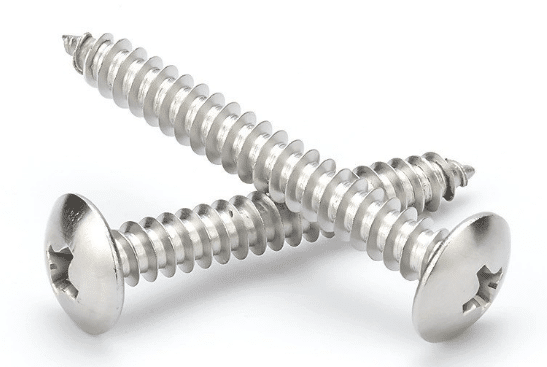

304 Stainless steel Self-Tapping Screws

304 stainless steel cross large flat head self-tapping screws

Self-Drilling Screw

The tail of the self-drilling screw is in the shape of a drill tail or a pointed tail, and no auxiliary processing is required.

Self-drilling screws are mainly used for the connection and fixation of certain thin plates, such as the connection between color plates and color plates, the connection between color plates and purlins, the connection of wall beams, etc.

The penetration force of self-drilling screws generally does not exceed 6mm, and the maximum does not exceed 12mm. Self-drilling screws are often exposed to the outside world, and they have strong corrosion resistance.

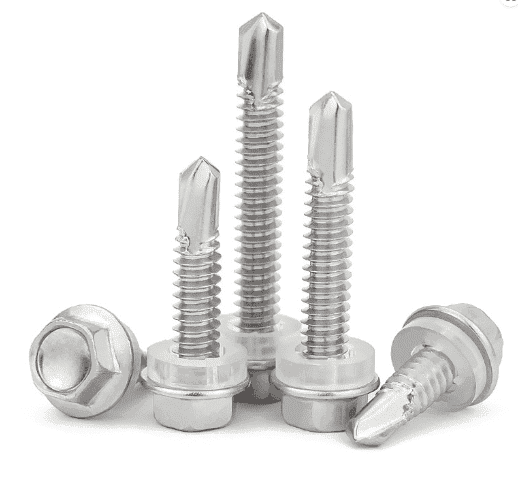

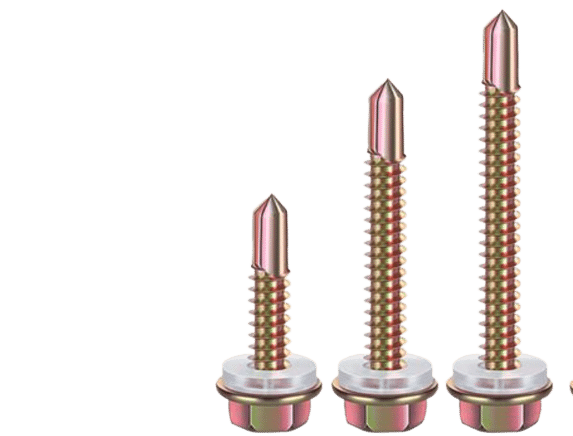

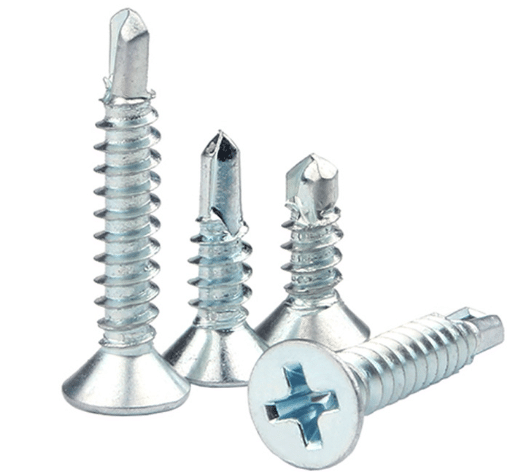

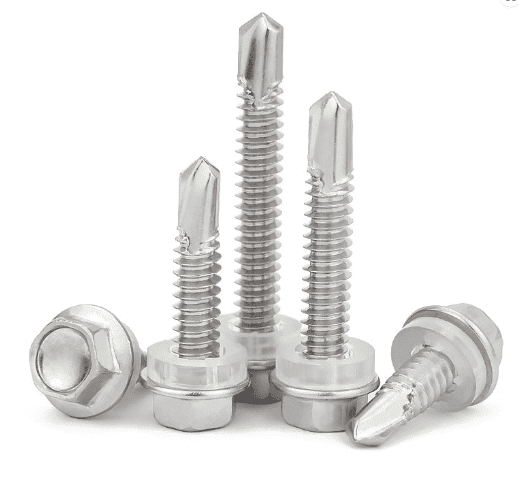

Cross Countersunk Head Self-Drilling Screws

Flange Self-Drilling Screws

Self-tapping screws and self-drilling screws are essentially the same kinds of screws, they do not require a tap and a nut to lock.

What is the difference between Self-tapping screws and self-drilling screws? The difference is the application environment. The harder the material, the harder the screw is to tap in, so the top of the self-drilling screw is similar to the drill bit, which makes it easier to break through the harder material, while for the softer material, the self-tapping screw is often used.

Materials, Types, and Uses for Self-Tapping Screws

Self-tapping screws are one of the widely used screws. Understanding the material and other knowledge of self-tapping screws can make us handier when purchasing.

Self-Tapping Screw Material

Self-tapping screws are usually made of carbon steel and stainless steel.

Generally speaking, carbon steel self-tapping screws do not have special alloying elements added, while stainless steel self-tapping screws contain higher alloy content.

The difference is that compared to stainless steel machining for self-tapping, carbon steel is more prone to rust, but its price is much lower than stainless steel.

The strength of carbon steel is higher than stainless steel, but the corrosion resistance is not as good as stainless steel.

Self-Tapping Screw Types

According to the material, self-tapping screws can be divided into carbon steel self-tapping screws and stainless steel self-tapping screws.

Self-tapping screws can also be divided according to their shape, use function, etc.

There are so many types of self-tapping screws, which usually can be divided into cross pan head self-tapping screws, pan head self-tapping screws, cross countersunk head self-tapping screws, drill tail self-tapping screws, flat tail self-tapping screws, and pointed tail self-tapping screws, triangular tooth locking self-tapping screws, etc.

The following are self-tapping screws mainly made of stainless steel

- Stainless steel drilling screws: Stainless steel drilling screws are also known as self-tapping and self-drilling screws, which can be divided into cross pan head stainless steel drilling screws, cross countersunk head stainless steel drilling screws, etc.

- Stainless steel crosses countersunk head self-tapping screws: There are two kinds of materials: SUS304 and SUS316, which are used to connect various materials.

- Stainless steel cross pan head self-tapping screws: There is no need to drill the bottom hole and tap the inner teeth when using it, just screw it in with a tool to lock it. The cross pan head tapping screw is made of stainless steel material, the thread is different from the general, the head tip distance is larger, and after drilling into the matrix, there are basically no chippings.

The Purchase Guideline for Self-Tapping Screw Materials

As mentioned above, carbon steel self-tapping screws and stainless steel self-tapping screws have their advantages and need to be purchased according to the situation.

If the budget is not large and there are no special requirements for the use time, carbon steel self-tapping screws can be used; if corrosion resistance and rust resistance are important, stainless steel self-tapping screws can be used.

Different functions of self-tapping screws have different practical applications.

For example, the above drill tail self-tapping screws are mostly used for the connection and fastening of colored steel plates, the cross pan head self-tapping screws can be used for the connection of metals and plastics, and the cross countersank head self-tapping screws are often used for the connection of various profiles.

The above is the relevant content of the difference between self-tapping screws and self-drilling screws. We hope it can help friends in need.

[title text=”Related Blog Post” tag_name=”h2″ link=”https://yijinsolution.com/category/news-blog/”]

[blog_posts style=”normal” columns=”3″ columns__md=”1″ ids=”3340,2617,3451″ image_height=”56.25%”]

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569