Description

Materials and Mechanical Properties of DIN7991 Hex Socket Countersunk Head Screws: Two materials are used for DIN7991 hex socket countersunk head screws: carbon steel and stainless steel.

The performance levels of hex socket countersunk head screw of carbon steel are 8.8, 10.9, and 12.9. GB3098.1 can be referred to.

Usually, carbon steel needs surface treatments, such as oxidization and electroplating. Negotiations can be performed if another surface coating or treatment is required.

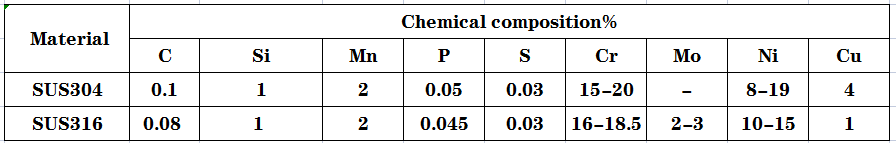

The common hex socket countersunk head screws of stainless steel on the market are mostly made of SUS304 and SUS316, both of which feature high corrosion resistance and high heat resistance.

With a medium machining hardness rate, SUS304 is suitable for common cold machining and drawing.

SUS316 has higher corrosion resistance and pit corrosion resistance than SUS304 and is especially suitable for seawater and chemical media.

Materials and Chemical Composition of DIN7991 Hex Socket Countersunk Head Screws:

1. How to Properly Choose a Hex Socket Countersunk Head Screw?

1)Before use, confirm that the product’s mechanical properties meet the customer’s operating requirements (such as the bolt’s tensile strength and the nut’s safety load).

2)The bolt length should be properly selected with the criterion that the bolt sticks out of the nut for 1 or 2 pitches after tightening.

3)Before use, keep the threads of the product clean.

2. How to Correctly Use a Fastener?

1)When tightening, make sure that the spanner’s force-applying direction is in line with the axis of the screw rod.

2)During tightening, apply the force in an even way within the safe torsion, and try to use a torque wrench or sleeve for coordination.

3)Two fast tightening leads to deadlocking. The use of an electric or pneumatic wrench is not recommended.

4)Keep the threads clean. To ensure smooth coordination between the nut and the screw, it is recommended to place the products in a clean container.

3. Maintenance Standard

1)If the removed screw or nut is slightly damaged, use a threading die and a screw tap for repair.

2)Apply oil immersion or oil lubrication to the removed and repaired screws and nuts for maintenance, and place them in order by specification, model, and purpose.

4. Scrapping Standard

The bolt with obvious cracks, broken threads, slipping, tensile deformation of the rod, cutting marks, or others can be scrapped only after being affirmed by the superior as irreparable.

Application Scope of DIN7991 Hex Socket Countersunk Head Screws:

Just like countersunk head screws, the DIN7991 hex socket countersunk head screw can have its head embedded in the component, with high connection strength.

An Allen wrench can used for its head, and a counter bore is required for installation that can keep the workpiece surface smooth and beautiful.

With advantages such as easy fastening and removing and a low occurrence of slipping, hex socket countersunk head screws are often used for machinery.

DIN7991 hex socket countersunk head screws also have wide applications in sports equipment, medical devices, and new energy vehicles.

Because the screw heads are not easy to see after installation, presenting more beautiful product appearances, they are favored in various industries.

Yijin Hardware provides hex socket countersunk head screws with standard countersunk angles, easier for the customers to install during service.

Yijin Hardware’s nonstandard hex socket countersunk head screws are also preferred by customers on the market.

With its demonstrated professional knowledge of the industry of customs hex socket countersunk head screws, Yijin Hardware has earned its customers’ trust and always been using its unique opinion on choosing hex socket countersunk head screws to give proven solutions professionally and manufacture custom hex socket countersunk head screws based on customer requirements!

Recommended: 2023 Top 10 Bolts And Nuts Manufacturers In China

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569