The development of advanced automotive technology is vital for crafting the high-quality vehicles we utilize in our daily lives. One way to make things is by using Computer Numerical Control (CNC) machines. These machines take a block of material and use a computer to cut away parts to create the desired shape. Automotive CNC machining parts is really important for making cars. It helps to make all the different parts of the vehicle, from the engine to the body, precisely how they need to be. This article will explain all the important points about car CNC machining, including how it’s used, why it’s good, and how it affects the car industry.

What is the Importance of Automotive CNC Machining in the Automotive Industry?

What is CNC machining, and how does it apply to the automotive industry? Automotive CNC machining is very important for making cars today because it produces intricate (very detailed), accurate, exact parts quickly with high quality. It helps make different parts of the vehicles, like the engine and the inner stuff, and helps make cnc cars that work well and are reliable.

Read More:

Precision and Accuracy

It is crucial to produce engine parts with great care, tight tolerance, and a high level of accuracy in order to function correctly and avoid potential hazards. CNC auto machining ensures the parts are made exactly right, reducing friction and damage. This makes the vehicle work better and last longer.

Complex Designs

Complicated Designs: Making modern car parts using regular machines would be hard or impossible because they often have very complicated shapes and complex geometries. CNC machining can create strong and lightweight parts that help cars perform better.

Material Versatility

CNC machines can work with many different materials, like plastics for the inside of things and metals for engine parts. Producers can choose the right material for each part, ensuring everything works well and is not too heavy.

Repeatability and Consistency

Exact reproductions of CNC machining programs help maintain consistent quality and size for all fabricated components. It is crucial to ensure that a large number of automobiles are safe and dependable.

Efficiency and Speed

CNC machining is faster and more efficient than manual machining. This helps car makers build cars better and respond quickly to customers’ wants.

Read More: CNC Machining vs Manual machining

Advantages of Automotive CNC Machining

Creativity and efficient prototyping are crucial in the dynamic world of vehicle design. This is the best spot for operating CNC automotive machining. Computer-controlled machines are used in CNC machining, which is a way to make things out of solid materials.

Rapid Prototyping

Prototypes can be produced rapidly with CNC machining instead of using slower methods like hand machining. Designers can try out different designs faster because of rapid turnaround, which means they can develop new ideas and get them to market faster.

Functional Prototypes

CNC machining has the capability to produce tangible prototypes, as opposed to techniques that only generate visual models. Testing the part under simulated conditions allows for identifying potential issues before mass production.

Cost-Effectiveness for Low-Volume Production

CNC machining can be cheaper than injection molding when making custom cnc car parts or special components in small amounts. CNC machining is good at making small amounts of parts. It’s great for making prototypes for cars, custom car parts, or unique components.

Iteration and Refinement

CNC-machined prototypes can be easily changed, which makes them really great. Designers can easily make changes to the design after testing and quickly create a new version, improving the design.

High-Volume Manufacturing

CNC machining is suitable for making a lot of things quickly, unlike regular machining, which relies on people’s abilities. Because it is done automatically, it can:

- Consistent production speeds that meet the requirements for making a lot of products.

- Production can grow more quickly because it relies less on skilled workers.

Integration with Automation

In car factories, computerized machining often works well with automated systems. This allows:

- Loading and unloading parts with machines makes manufacturing even more efficient.

- Connecting with robot arms to put things together and move things around tasks.

Complexities Made Simple

Complicated patterns can frequently be found in newly manufactured car parts. CNC machining can easily deal with these problems so that it can make:

- High-quality, light engine parts.

- Parts that make a vehicle work better and use less fuel.

- Intricate interior parts and usefulness mixed with complicated pieces.

Reduced Waste and Improved Sustainability

You can change CNC machining to work for different sizes of production. CNC machining can produce a wide range of items, from mass-producing automobile components to crafting bespoke parts for unique vehicles.

CNC machining is more exact than regular machines, so it doesn’t waste as much material.

This signifies that there will be opportunities for people who create things to save money. Making goods that are more sustainable for the environment.

Automotive CNC Machining Production In the Automotive Industry

Modern cars are made using CNC machines. Imagine the fancy parts inside the car, the strong but light frame, and the smooth, aerodynamic shape of a car. CNC machining is important for making parts accurately and consistently. And this is how CNC machining helps make cars.

Engine components

These perplexing parts, such as cylinder heads and crankshafts, require high-accuracy machining. The intricate cooling passages and valve seats that are necessary for engine performance can be made with CNC machining.

Engine blocks

We can use CNC technology to shape engine blocks made from cast iron or aluminum. This process can make the right size holes and spaces for the pistons and other engine parts. CNC machining can also produce other engine elements, such as camshafts, connecting rods, and pistons.

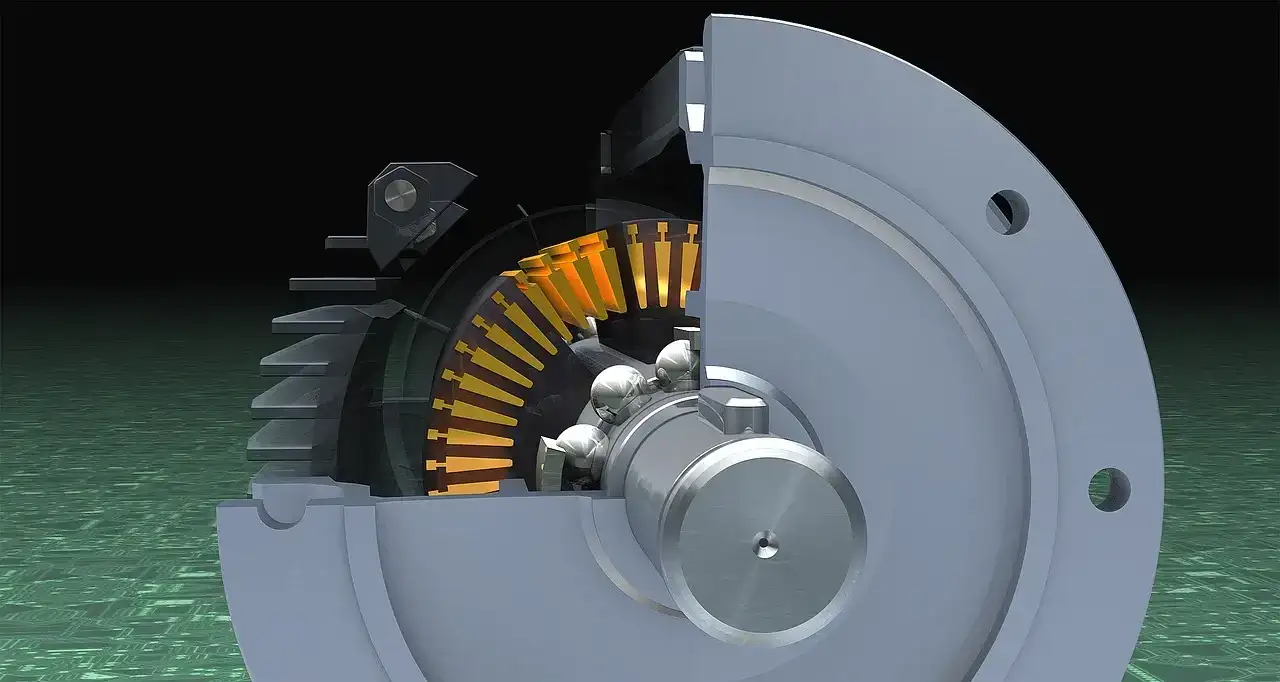

Drivetrain components

CNC machining is utilized to produce transmission components, differentials, driveshafts, gearboxes, differential housings, and axles. These parts move power from the engine to the wheels and must be durable and dependable.

Suspension & Interior components

CNC machining creates various suspension parts, including control arms, knuckles, sway bars, and tie rods. These pieces have to be sturdy but light so that the car can easily control and have a smooth ride. Similarly, Parts, like dashboards, instrument panels, and door handles inside vehicles are manufactured using CNC machining.

Braking system components

Brake discs need to be made very carefully to work well and keep you safe when you brake. CNC machines can make very smooth surfaces and precise dimensions for braking components such as drums, rotors, and calipers. Similarly, for brake calipers, it is imperative to craft brake calipers with precision to ensure they apply the correct pressure on the brake discs, enabling the vehicle to come to a safe stop.

Custom Parts

Performance parts like custom exhaust parts, intake manifolds, and turbocharger parts are made using CNC machines to meet specific design and performance goals. Custom wheels are also designed for custom requirements. If you want custom parts for your next project, consider us and ask any question you have in mind, as we have produced plenty of custom parts for our global clients.

Popular Automotive CNC Machining Part Materials

It’s important to pick the right automotive cnc machining material for car parts. When choosing materials for car parts, car makers consider weight, strength, how well it works, and how much it costs. What are some of the materials commonly used in automotive CNC machining? Here are some of the most popular materials for making car parts:

Steel

This is the common material used to make cars. So, steel is used for engine blocks, crankshafts, and car frames because it is extremely durable. And it can handle high heat and pressure, and it helps build the car’s basic structure.

- The basic parts of the car’s frame and chassis form its primary structure. Engine parts that can handle very high temperatures and pressure. Body panels protect people in a crash.

- Doors and other parts of buildings use panels.

Aluminum

Aluminum is lighter than steel and has some advantages, such as being better at resisting rust and helping to make vehicles more fuel efficient and perform better.

- Heat can easily move through it to help manage the temperature of engine parts.

- It is often used for engine parts like intake manifolds, cylinder heads, and pistons.

- Wheels are made to be lighter to improve the car’s performance and handling.

- Body panels are used to make the car’s body weigh less.

Plastic

More and more engineering plastics are being used because they are light, don’t corrode, and can be used for many different things. Some examples of these plastics are ABS, nylon, polycarbonate, and PEEK. And they are used in lots of different things like car parts, insulation, and interior panels in buildings. Composites are a great choice for outside panels and structural parts because they can be as strong as metal but much lighter.

- Engine parts like intake manifolds and valve covers are made to withstand heat and chemicals.

- Further, exterior parts like bumpers and other pieces are found in some cars.

- Interior parts like dashboards, door panels, and seats are lightweight, easy to design, and affordable.

Magnesium

Because magnesium is a very light metal, it is used to make car parts like engine blocks, wheels, and transmission cases to make the car lighter. Magnesium mixtures are good at reducing vibrations and are strong compared to their weight, even though they are light.

Carbon Fibre

- This high-tech material is solid and stiff but also very light.

- And used on the body parts of fast cars to make them weigh less and handle better. “High-end cars in certain areas increasingly use it because it looks good and can create unique designs. “

Glass

Glass is a good choice for car windows, windshields, and mirrors because it is strong, and you can see through it easily. Specifically made to keep people safe in modern cars, breaking into small pieces to reduce injury if there’s an accident.

Automotive CNC Machining Vs 3D Printing In the Automotive Industry

How does CNC machining differ from 3D printing in automotive applications? CNC machining and 3D printing are highly used to make lightweight cnc automotive parts. Here is a comparison table to help you understand both and which one is right for you.

| Process | CNC Machining | 3D Printing |

| Principle | Subtractive (removes material) | Additive (layers material) |

| Strengths | High Strength & Accuracy | Design Complexity & Prototyping Speed |

| Applications | Mass Production & Vast Material Options | Limited Production & Material Options |

| Limitations | Limited Design Complexity | Strength & Production Limitations |

Choosing the Right Tool

Production vs. Prototyping: CNC machining is a very good way to make a lot of very accurate parts. 3D printing is a good choice for trying out detailed ideas and making them quickly.

Materials Needs: CNC machining is the best choice if the part needs a specific material that is hard to get for 3D printing.

Complexity of the part: Because 3D printing builds shapes by adding material, it can create intricate designs with inner structures.

Yijin Hardware: Best Automotive CNC Machining Service for You

At Yijin Hardware, we know making car parts with precision, efficiency, and reliability is important. That’s why we offer the best CNC machining services that will exceed what you expect and meet all your needs. Our services include.

- Unmatched Precision and Quality

- Extensive Material Selection

- High-Volume Production Capabilities

- Prototyping Expertise

If you are ready to experience Yijin differences, contact us today or visit our website to learn more about our automotive cnc machining services and capabilities. Don’t settle for anything less than the best – partner with Yijin Hardware for your CNC machining needs!

Conclusion

Basically, automotive CNC machining is now really important in the automotive industry. This technology enables automotive manufacturers to consistently produce reliable and high-quality vehicles by creating precise and complex parts. CNC machining will keep improving and leading the way in making car parts, pushing the limits in design and function to meet future needs. CNC machining is important for making cars, as it helps to use stronger and lighter materials and make electric vehicles.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569