Manufacturing companies lately depend on CNC, or “computer-controlled machining machines.” This is for producing components and items. CNC moves tools and machines around using computer software. This software is intended for this process.

CNC machinists are individuals trained in using these machines and software. This helps them properly set up and work optimally. Before CNC technology was used for this kind of work, businesses relied upon manual machining, which requires one technician per machine.

Manual cutting may be used less often. Yet, it can still be invaluable in certain circumstances. Read further to gain an understanding of CNC machining vs manual machining!

Difference Between CNC Machining and Manual Machining

One major difference between CNC machining and manual machining lies in their respective staff needs during each stage of processing. A qualified worker may operate many tools at the same time under CNC. But, one specialist must be assigned for every machine being manually worked upon.

It is a must to know the main differences between these two manufacturing methods. This will help us understand how they can be used in business and manufacturing settings. Let us look closer at each strategy to see what sets it apart. As well as any effects or implications it might have in specific sectors or industries.

Read More:

What is CNC Machining?

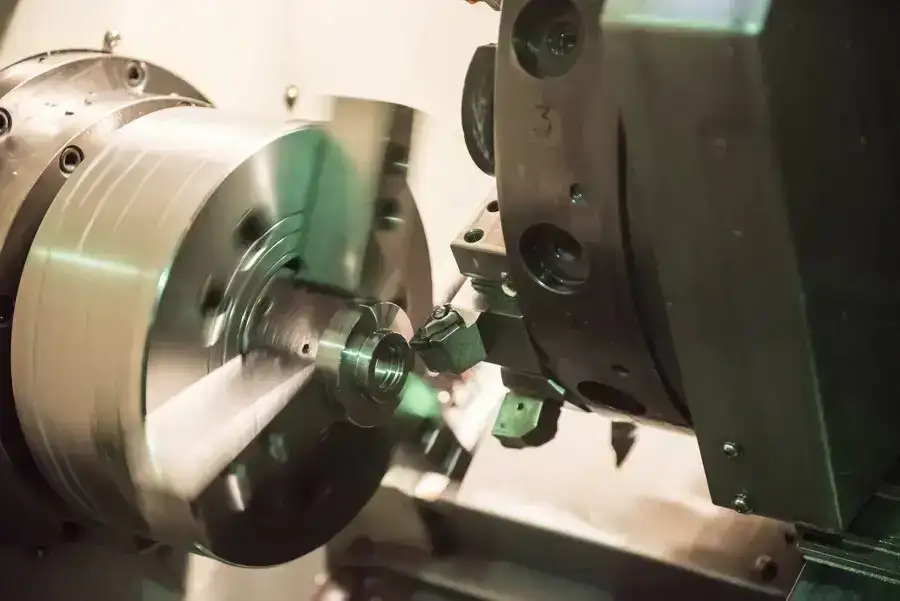

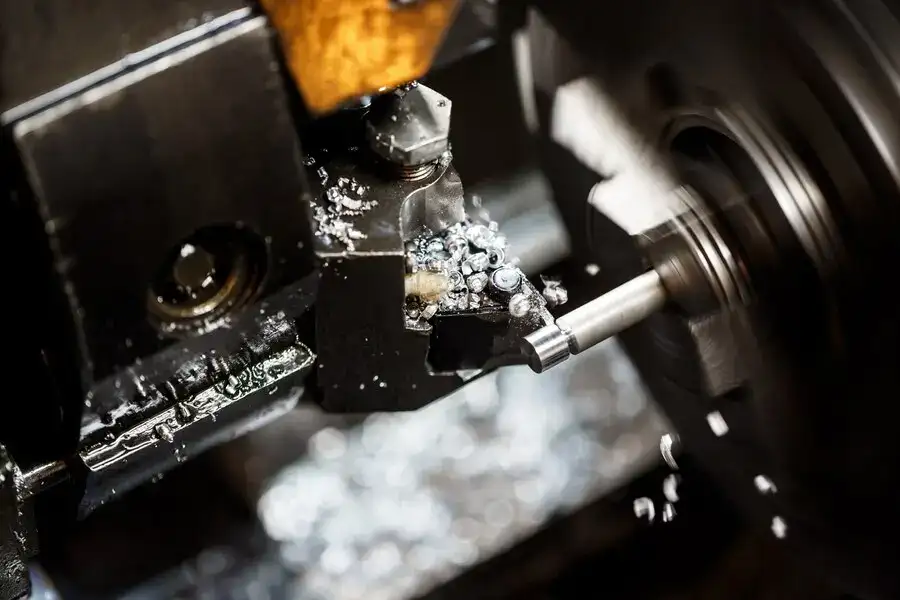

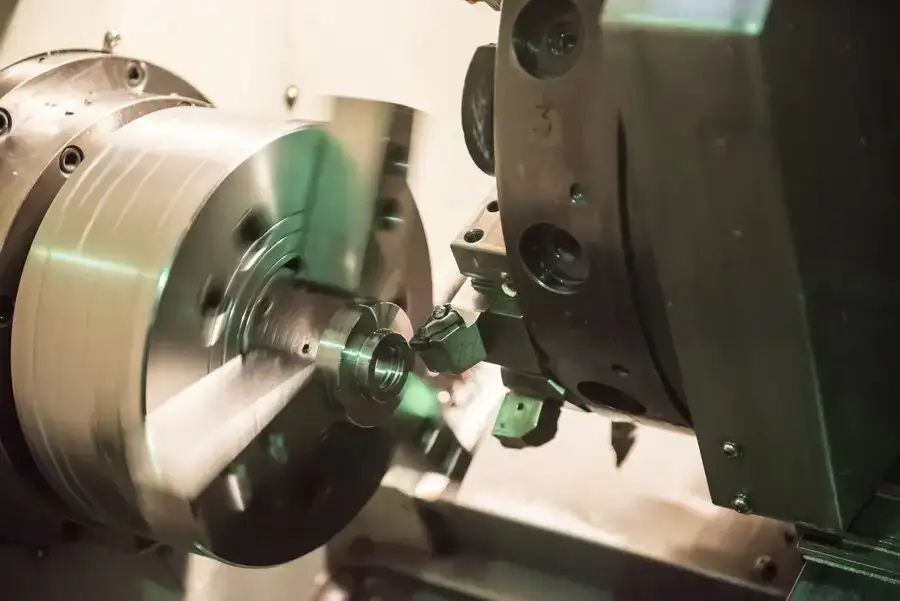

CNC is an industrial manufacturing method in which automated systems control cutting tools to remove material from workpieces. Since its introduction in the middle of the 20th century, it has proven highly scalable from prototyping to mass production. The field of computer science’s continuous evolution is a major reason why it continues to gain prominence today.

Read More:

What is Manual Machining?

As the name suggests, Manual machines use workers to move the cutting tool and take material off from the workpiece. The cutting tool in this method can be easy or complex, but an operator does the relative movement.

Pros and Cons of CNC and Manual Machining

Advantages of CNC Machining

- Due to the exact direction of the cutting tool in as few increments as desired, the process is very precise.

- Since there are no humans regulating the cutting tool, there is no chance of human error.

- CNC machines take consistency to the higher level, and all the parts look precisely the same. This is likely required in bulk production.

- Due to the high precision, the research and prototyping department can visualize what the final product would look like exactly.

- Once programmed, CNC machines can operate with minimal human intervention, maximizing productivity.

Disadvantages of CNC Machining

- CNC equipment demands high initial investment since the machines are costly.

- There is an extra stage of computer programming, which needs a skilled programmer to create the codes for the components.

- The quality of machine operations is dependent on the operator’s skill. Thus, a professional machinist is a must for an ideal result.

- Because of higher automation and a decrease in labor requirements, unemployment has increased.

Advantages of Manual Machining

- Manual machining has a lower initial investment cost.

- There is no need for programming to machine the segments. The professional machinist can operate the part directly.

- Manual machining can handle customization well. This is because small changes in projects do not need to start from scratch.

- In case of malfunction, machines like manual grinding are quick to fix, and the cost of repairs is low.

Disadvantages of Manual Machining

- The manufacturing speed of this method is quite slow-moving. What CNC machining can perform in a few minutes can require hours of manual machining.

- It cannot handle the modern large-scale production requirements and numbers.

- The accuracy of manual machining is quite precise and adds human errors.

- Due to a lack of precision and a higher chance of error, there are more denials. This causes higher waste and increased costs.

The True Cost Difference between CNC and Manual Machining

The true cost difference between CNC machining vs manual machining is significant. It’s essential to consider this difference when making informed decisions. Let’s conduct an in-depth examination supported by concrete data. Our goal is to better comprehend both approaches. We will focus on their financial repercussions.

Cost Comparison Analysis:

To conduct a comprehensive cost analysis, we’ll consider various factors. This influences the overall expenses incurred in CNC vs manual machining processes. Here’s a breakdown:

| Cost Factors | CNC Machining | Manual Machining |

| Equipment | High initial investment | Lower initial investment |

| Labor | Lower labor costs | Higher labor costs |

| Programming | Software and training costs | N/A |

| Material Waste | Minimal waste | Moderate waste |

| Maintenance | Regular maintenance costs | Lower maintenance costs |

| Flexibility | Limited flexibility | Higher flexibility |

As mentioned before, CNC machining requires greater initial investments and programming costs. Yet, its benefits extend beyond labor savings and material waste savings. They include long-term maintenance savings. Manual machining offers lower upfront costs. But, it is likely more labor intensive with increased material waste risks.

Read More: Best CNC Machining Companies In China

How to Choose between CNC Machining and Manual Machining

Before choosing between CNC vs manual machining for your manufacturing needs, keep these factors in mind:

Production Volume: CNC machining can provide greater efficiency for large-volume runs. It also offers increased accuracy for runs with consistent designs. But, manual machines can provide flexibility and cost for small batches or custom projects.

Complex Designs: If projects involve intricate or tight tolerance designs, CNC can offer precision. This will be needed to meet these specifications. Something manual machining may struggle with when dealing with more intricate geometries.

Budget Constraints: Consider your financial limitations when making an initial investment for CNC equipment. Compare these limitations with ongoing manual machining labor costs. Decide on which option aligns best with your financial resources and long-term goals.

Timeline and Lead Times: Assess your production timeline and lead time requirements. CNC machining provides faster turnaround times for large-scale production runs. Manual machining is for quick prototyping or small-scale production with shorter lead times.

Choose Yijin Hardware for Your Machining Needs

Yijin Hardware’s CNC machining services specialize in providing exceptional parts. These parts are tailored to meet the precise requirements of various industries. Automotive, aerospace, medical, and others are among the industries we serve. With state-of-the-art CNC machines and our experienced team behind each one of them, our results speak for themselves every time! Stay in touch with us now so we can discuss how our expertise can help achieve your manufacturing goals!

Conclusion

CNC and manual machining both offer distinct benefits. These make them suitable for different manufacturing applications. When making a decision, consider your production requirements, budget constraints, and long-term goals. Yijin Hardware offers expertise and advanced technology to support both CNC or manual techniques. For precision and efficiency, utilize CNC techniques at Yijin Hardware. For versatility and cost efficiency, consider manual techniques. Both are available here. Contact us today to learn more and experience the difference with Yijin Hardware.

FAQs: Common Questions about CNC Machining and Manual Machining

A set of frequently asked questions (FAQs) about CNC and manual machining

Q: What distinguishes CNC milling from manual machining?

A: The main difference between CNC and manual machining is how they work when they need to produce precise results. With CNC machining, precise results are produced by computer-run machinery, while with hand machining, expert machinists directly handle manual equipment.

Q: Does CNC Cutting or Hand Machining Cost Less?

A: Cost-effectiveness depends on various factors. These factors include Quantity produced, Design complexity, and Budget constraints. CNC machining often provides greater cost-efficiency. Manual milling may be preferable for smaller batches or unique applications.

Q: Can CNC tools create intricate forms and designs with high accuracy and precision?

A: They can navigate intricate courses and curves programmed into the machine’s software.

Q: How Long Will It Take to Establish a CNC Machine?

A: The time required to set up a CNC machine depends on the complexity of its design process. Basic programs may take only minutes to set up. More intricate designs, however, could require hours or days to create and modify due to the level of programming skills required.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569