Before understanding CNC Machining basic knowledge, let’s look at the current growth of the machining industry. Global metal parts manufacturing is witnessing a massive transformation, especially in machining. For instance, Industry 4.0, with the help of Artificial Intelligence (AI), the Internet of Things (loT), and big data, is redefining intelligent manufacturing technologies. Now, we see advanced level precision from product design to manufacturing.

Before understanding CNC Machining basic knowledge, let’s look at the current growth of the machining industry. Global metal parts manufacturing is witnessing a massive transformation, especially in machining. For instance, Industry 4.0, with the help of Artificial Intelligence (AI), the Internet of Things (loT), and big data, is redefining intelligent manufacturing technologies. Now, we see advanced level precision from product design to manufacturing.

However, if you are a beginner with zero knowledge of CNC machining, this guide is for you. In this article, we shall try to explore the basics of CNC machining and some of the most relevant concepts, such as:

- Machining principles

- CNC machining Types

- Design considerations

- Material Choice

- Applications

- And different surface finishing options

CNC machining being a cornerstone technology is continuously evolving and adapting latest trends such as:

- Robotics and Automation

- Additive Manufacturing

- AI-powered Predictive Maintenance

Due to automation, machining centres can now manufacture complex parts with greater precision.

Simultaneously, the following statistics demonstrate the unprecedented growth of CNC machining companies in 2023:

According to research by Grand View Research, the global CNC machining market was valued at USD 66.74 billion in 2023.

What is CNC machining?

CNC machining is an abbreviation of Computerized Numerical Control Machining. Simply put, it is a technology for manufacturing high-precision parts. The entire process is automated. Automation means the manufacturing process as a whole is controlled by a computer. From design to part manufacturing, there is no manual input. Yes, we need an operator to fix the tools and workpiece.

Read More:

CNC Machining vs Manual Machining

Why CNC machining is important?

Metal parts manufacturing is continuously evolving. Companies are seeking high-precision and affordable ways to manufacture these parts. CNC machining is the solution.

Modern CNC technology ensures optimum accuracy, speed, and low surface roughness. Now, machining centres are capable of producing complex shapes with tight tolerances. However, for a perfect CNC project, it is essential to follow all protocols, which include the type of materials, cutting tools, and axis of the machines.

For instance, traditional 3-axis machines can work on the X, Y, and Z axes. On the other hand, modern 5-axis CNC machines add two more rotary axes. It further allows the machining of complex geometries in multiple directions. 5 Axis CNC machining gives the following advantages:

- Reduced set-up times

- Enhanced surface quality

- Increased design freedom

Read More: Top 10 China CNC Machining Service Suppliers

CNC Machining Working Principle

We have understood that CNC machining parts have broad applications. Whether it is automotive, aerospace, medical, or electronics, we can see the significant role of precision machined parts everywhere. But, we need to learn how modern CNC machines transform a part design into a complete product.

We have understood that CNC machining parts have broad applications. Whether it is automotive, aerospace, medical, or electronics, we can see the significant role of precision machined parts everywhere. But, we need to learn how modern CNC machines transform a part design into a complete product.

Get a deeper insight into CNC machining fundamentals by watching the following video:

1. CAD Design

To understand the basic CNC machine design, imagine you have a well-designed metal part in your hand; it must have gone through a complex process. This metal-forming process starts with CAD Software. Using this software, CNC parts designers create a 3D model. The designed model carries the following information:

- Geometry

- Dimensions

- Tolerance

2. CAM Programming

The next step is translating the CAD model into instructions that a CNC machine can easily understand. For this purpose, we use a CAM software. Computer Aided Manufacturing Software generates a G-code that carries the machine’s complete instructions, such as how to move tools and workpieces to make a particular shape.

3. Machine Setup

It is the 3rd step in CNC machining. When G-code is ready, it is transferred to the machine controller. The CNC machine operator mounts the desired material for processing on work-holding systems following appropriate tool placement. This material can be metal, plastic, or wood.

4. Machining Process

Finally, the CNC machine is ready to execute G-Code. Following the pre-programmed instructions, the machine controls the movement of cutting tools and workpieces along the X, Y, and Z axes. This process continues in section y until we receive the final shape developed in the 3d model phase. Generally, this machining process involves the following operations:

- Drilling

- Milling

- Turning

5. Quality Control & Final Inspection

When the machining process is complete, the skilled machine operator carefully examines the finished part. This step is essential to ensure desired specifications and tolerances when referring to CNC machining. Similarly, surface treatment is carried out to give a perfect look, such as deburring or polishing.

Read More:CNC Machining vs Injection Molding

Types of CNC Machining

If we read CNC machining fundamentals, there are mainly four types of CNC machining:

If we read CNC machining fundamentals, there are mainly four types of CNC machining:

- Milling

- Turning

- Drilling

- Laser-cutting

Each type is suitable for specific applications following custom part geometries. Therefore, getting the gist of these four types of machining is crucial to obtaining the desired results. Let’s discuss each type precisely by overviewing its advantages and applications.

1. Milling:

As mentioned above, the cutting tool moves around multiple axes following a computer program in CNC milling. It makes precise cuts to give a defined shape. Moreover, it can drill holes and develop complex shapes on numerous materials such as metal, plastic, wood, foam, and composites. Milling machines come in various sizes, such as desktop and large industrial machines.

Advantages:

- Can produce complex features; pockets, slots, and contours.

- High precision with smooth surface finishing.

- Suitable for a wide variety of materials metals, plastics, and wood.

Applications:

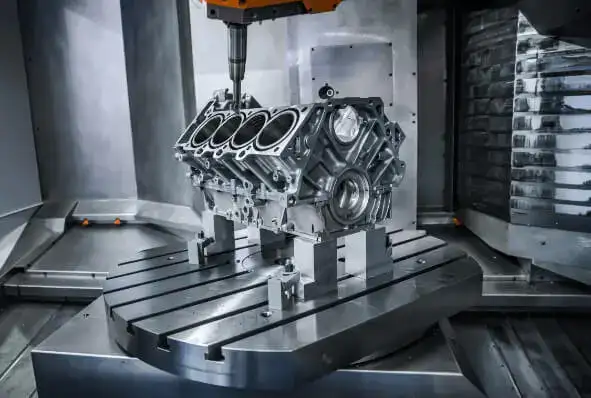

- Manufacturing engine parts.

- Custom metal parts.

- Complex aerospace and medical parts.

2. Turning:

CNC turning is another type of machining which helps you understand CNC basics. In this type of machining, the operator mounts a workpiece on the spindle that rotates at high speed. A single-point cutting tool removes the material during this operation until we get the programmed shape. During this process, the cutting tool can move along radially and axially. It helps to create features such as grooves, threads, chamfers, and tapers.

Advantages:

- Effective in making symmetrical parts like shafts, discs, and rings.

- High Precision.

- Best for mass production.

Applications:

- Automotive parts manufacturing.

- Medical implants and surgical instruments manufacturing.

3. Drilling:

In CNC machining, we define drilling as a process where a rotating drill bit makes round holes in a workpiece. This process begins with clamping the workpiece onto the machine’s fixture. The operator selects and mounts a suitable drill bit on the machine spindle. Later, a CNC program guides the drilling operations. These operations usually include tool movement, spindle speed, and feed rate.

Advantages:

- Suitable for producing holes with accurate positions and diameters.

- Can be combined with other CNC machining processes.

- It is suitable for a wide range of materials

Applications:

- Holes for fasteners, and assembly components.

- Dowel pins.

- Machining holes for rivets.

4. Laser Cutting:

Laser Cutting is considered one of the highest precision machining types in CNC machining. In laser cutting, a laser beam cuts through the given material with optimum accuracy and speed. The rest of the process is similar, where a computer program navigates the machine to manufacture the designed shape on the workpiece. One of the good features of this type of machining is that there is minimum material waste and tool wear and tear.

Advantages:

- High precision with minimum material waste.

- Less post-processing.

Applications:

- Manufacturing sheet metal parts.

- Stencils and signage.

Apart from these four CNC machining above, in the manufacturing industry, there are many other machining operations that have their own advantages and disadvantages. Feel free to read the blog “12 Types of Machining Processes” for more information.

CNC Materials for Machining

To understand CNC basics, the following table carries the most suitable materials for the CNC machining process.

| Material Category | Examples | Advantages | Disadvantages |

|---|---|---|---|

| Metals | Aluminum (6061, 7075) Steel (AISI 1018, 304 stainless steel) | High strength properties | Can be expensive for certain materials |

| Plastics | ABS Nylon (Polyamide- Acrylic (Polymethylmethacrylate) Delrin (Polyacetal) | Lightweight and cost-effective | Lower strength and heat resistance |

| Composites | Carbon Fiber Reinforced Plastics (CFRP) Fiberglass Kevlar-reinforced polymers | High strength-to-weight ratio | More complex and expensive |

How to choose the right material for your project?

Choosing the right CNC machining material for your project involves several factors. Let’s try to figure out each step by step:

- Project Requirements

- Material properties

- Design considerations

You can start with project requirements involving part function, strength, and dimensional accuracy. The next stage is considering material properties such as features and cost. The final stage is design, where we undertake points like geometry and preferred surface finishing options.

If you need clarification about choosing the best material, taking the help of a professional CNC machining company can play a decisive role because an expert opinion can save both time and money.

Designing for CNC Machining

In CNC machining, parts accuracy, and performance significantly depends on the right design. The role of CAD software must be maintained in modern CNC machining. These software assists in developing 3D models of required parts. Generally, 3D models carry the following information:

- Geometry

- Dimensions

- Tolerance

In CNC machine design, it’s essential to undertake several key factors to achieve the best results. These are:

- Machinability

- Tool Accessibility

- Wall Thickness

- Minimize Features

- Standardization

The next step is defining variations in the dimensions of your design. If you have tighter tolerances, you will require more precise machining. Subsequently, specify the desired surface roughness. If you need smoother finishing, the part will require more post-processing.

Finishing Processes in CNC Machining

According to the CNC basic knowledge, you can say that finishing is the post-processing of a CNC machined part. It gives both the desired appearance and functionality. Below, we have discussed some common surface finishing techniques.

Sanding and Polishing:In this method, CNC machining centers use abrasive materials to make the part’s surface smooth like machining marks.

Bead Blasting:In bead blasting, we use a pressurized stream of small abrasive beads. Bead blasting is used to achieve a matte finish.

Anodizing:This is an electrochemical process. Anodizing creates a protective oxide layer on the surface of aluminum parts.

Powder Coating:Powder coating is a dry finishing technique. In this method, we apply a layer of finely ground powder to the part.

Painting:Painting provides an additional layer of protection and it comes with various color options for better aesthetic appeal.

CNC Machining Applications

The application of CNC machining is extensive. Machining products are everywhere. This section will explore some of the most popular industries where machined parts are in high demand.

Aerospace

CNC machines can manufacture airframe components. Examples of Aerospace machining parts are lightweight fuselage panels, complex engine mounts, and landing gears. Similarly, CNC machines can make engine parts like turbine blades, compressor disks, and combustor liners. Moreover, we can manufacture precise and reliable flight control systems.

Automotive

Examples of CNC Machined Parts for the automotive industry are engine components such as blocks, cylinder heads, pistons, connecting rods, crankshafts, and camshafts. CNC machines manufacture all these parts. Similarly, we can make transmission parts like gear housings and synchronizer rings using this technology.

Medical

Modern complex medical parts can’t be imagined without CNC machines. These machines bring an extreme level of accuracy. Examples of medical CNC parts are surgical instruments such as scalpels, forceps, bone drills, and laparoscopic tools. Similarly, with CNC machines, we can also develop orthopedic and dental implants such as bone plates and screws.

Electronics

It won’t be wrong to say that the electronics industry is one of the biggest beneficiaries of CNC machining. It has given space to significant businesses like circuit board manufacturing, heat sinks and cooling solutions, and other shielding enclosures, connectors and ports, and RF components.

Prototypes

Apart from its applications in various industry, CNC machining is widely used for rapid prototyping as well. It allows engineers and designers to create functional prototypes with high precision and accuracy. These prototypes serve as models that demonstrate the functionality of a design before mass production begins.

The advantages of using CNC machining for prototypes are significant. It enables the production of complex geometries, intricate details, and precise dimensions that closely resemble the final product. This level of accuracy is crucial for evaluating the performance, fit, and functionality of the prototype.

CNC Machining Pros and Cons:

CNC machining comes with several advantages that we have already discussed but there are some cons too. Reading the pros and cons of CNC machining will extend your CNC machining basic knowledge:

Pros of CNC Machines:

High Precision and Accuracy:

CNC machines are highly effective in manufacturing custom parts with tight tolerances and complex geometries.

Consistency in Mass Manufacturing:

Since CNC machines work on automation, they are extremely efficient and consistent in producing large-batch custom parts orders.

Materials Choice:

CNC machines can undertake a wide range of materials such as steel, aluminum, ABS, Nylon, and other composites.

Reduced Cost:

Since there is very limited human involvement, CNC machines can produce parts at low cost. Mass orders will further decrease the overall price.However, there are some cons too which we are going to discuss below:

Cons of CNC Machines

High Upfront Costs:

Modern CNC machines are quite expensive. Furthermore, they are difficult to maintain. Subsequently, the part cost can vary following design.

Material Waste:

To obtain the desired results, CNC machines generate significant waste. However, 5-axis CNC machines have reduced this phenomenon because they can work on 5 axes at the same time which minimizes waste.

Why Choose Yijin Hardware as Your First CNC Choice?

Yijin Hardware combines over 25,000 square meters of manufacturing space with advanced equipment, including CNC machining centers, lathes, laser cutting machines, and more. We offer best CNC machining service, and effectively collaborate with clients to design and manufacture complex parts with high precision and tight tolerances. We have the following equipment:

We have the following equipment:

- CNC core Lathe

- Secondary machining Workshop

- 5-Axis CNC Machining Workshop

- Electroplating factory

- Quality Testing Equipment

If you want to place an ODM/OEM order, you can send us the picture, drawing, or prototype for turnaround time and cost estimation.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569