Description

[section]

[row]

[col span__sm=”12″]

1. After quenching and before tempering, the steel with a hardness higher than HRC55(up to HRC62) is up to standard. The top hardness in actual application is HRC55 (HRC58for high frequency quenching).

2. The thermal treatment process of carburization quenching is not used for the #45 steel. After thermal refining, the custom cnc milling components has good general mechanical properties and are widely used for various important structural parts, especially those connecting rods, bolts, gears and shafts that operate under alternating loads. But these custom cnc milled parts have low surface hardness and poor abrasion resistance. Thermal refining + surface quenching can be performed to improve custom cnc milled components surface hardness.

[row_inner]

[col_inner span=”7″ span__sm=”12″]

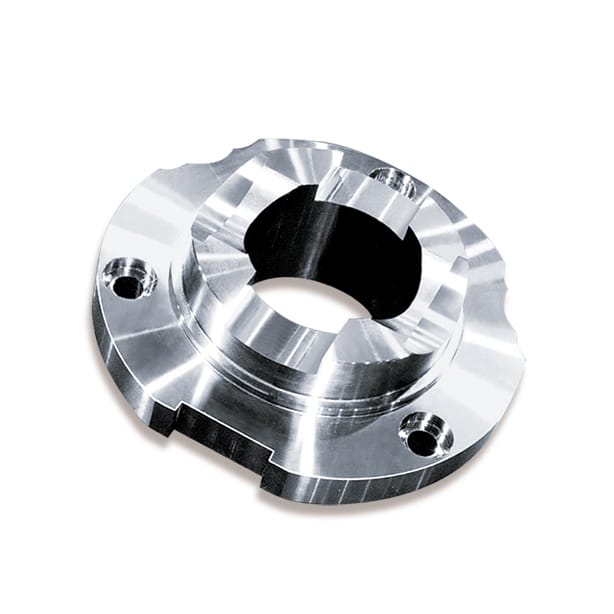

Purpose of the #45 steel:

It is applicable to manufacturing motion milling machine parts with high strength such as air compressors, pump pistons, and steam turbine impellers, as well as rolled shafts, connecting rods, worms, racks, gears, and pins in heavy and general machinery.

Usually, the #45 steel is used in the tempering or normalizing state and can replace the carburizing steel for the manufacturing of parts with surface abrasion resistance, including crankshafts, gears, machine tool spindles, piston pins and transmission shafts, after high-frequency induction and flame quenching. It can also be used to manufacture moderate load shafts, threshing cylinders, recess plate nail teeth, chain wheels, gears and fitter’s tools of agricultural machinery.

[/col_inner]

[col_inner span=”5″ span__sm=”12″]

[ux_image id=”1476″ image_size=”original”]

[/col_inner]

[/row_inner]

As described above, the #45 steel can be used to manufacture all kinds of custom CNC milled parts, so this custom CNC milled part has very wide application. Let Yijin Hardware give you some examples: core components for auto engines, core components for auto brakes, gears, and pistons. Since it is a custom CNC milling machine part, you just need to show your requirements, and any custom CNC milling factory with superb technologies can give you what you want.

[/col]

[/row]

Machining Difficulties and Cautions of the the #45 Steel cnc milling component

[row v_align=”middle”]

[col span=”7″ span__sm=”12″]

For the #45 steel, the cutting speed has an direct impact on the cutting efficiency. If the cutting speed is too high, the cutting time can be reduced but the cutter overheat is unavoidable, affecting its service life. If the cutting speed is too low, the cutting time is prolonged with low efficiency and the cutter cannot exert its functions. There are a lot of factors affecting the cutting speed.

After quenching and tempering, a workpiece has high strength but insufficient toughness if its carbon content is too high, and improved toughness but insufficient strength if its carbon content is too low. To make the workpiece have good overall performances after quenching and tempering, its content of carbon is usually controlled between 0.30 – 0.50%.

[/col]

[col span=”5″ span__sm=”12″]

[ux_image id=”1477″ image_size=”original”]

[/col]

[/row]

[row v_align=”middle”]

[col span=”5″ span__sm=”12″]

[ux_image id=”1478″ image_size=”original”]

[/col]

[col span=”7″ span__sm=”12″]

During quenching, the whole section of a cnc milling machining workpiece needs to be covered so that it has the microscopic structure primarily composed of fine needle-shaped quenched martensites. High-temperature tempering allows it to have the microscopic structure primarily composed of average tempered sorbites.

High quenching temperature accelerates custom cnc milling components heating, reduces surface oxidation, and improves work efficiency. To achieve austenite homogenization for the custom cnc milling components, sufficient soaking time is required. If the actual batch is large, the soaking time needs to be prolonged properly

[/col]

[/row]

Otherwise, insufficient hardness may occur due to uneven heating. If the soaking time is too long, coarse grains and serious oxidation and decarbonization occur, affecting quenching quality. We think the soaking time needs to be prolonged by one fifth if the batch is greater than what is specified on the process document.

[row]

[col span__sm=”12″]

Does Yijin Hardware Provide Custom CNC Milled Parts of Other Materials?

Yes. In the past 20 years, Yijin Hardware has provided professional services and products of various materials for thousands of customers and been praised by all of them. Yijin Hardware is a recognized custom CNC milled parts manufacturer because of high quality, low allowance, operation engineers with rich experience, quality custom CNC milling services, and advanced machines, instead of low prices. And we are going to do even a better job with all of these in future.

[/col]

[/row]

[/section]

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569