Description

[section]

[row]

[col span=”6″ span__sm=”12″]

About Nylon

Polyamide, also known as nylon and PA for short, is a generic term of thermoplastic resins with repetitive amide groups [NHCO] on the main chain of the molecule, including aliphatic PA, aromatic-aliphatic PA and aromatic PA. Invented by a famous American chemist Wallace Carothers and his scientific research team, the aliphatic PA has a lot of varieties, large yield, and wide application. The naming is based on the number of carbon atoms of the synthon. Polyamide (PA, aka nylon) is a resin used for fibers which was first developed by an American company – Dupont and industrialized in 1939. In 1950s, injection-moulded items started to be developed and manufactured to replace metals, meeting the requirements of light weight and reduced cost for downstream industrial products. With a lot of repetitive amide groups on its main link, polyamide is called nylon when used as plastics and chinlon when used as synthetic fibers. Polyamide can be made from diamine and binary acid or synthesized with ω-amino acid or cyclophosphamide. Several different polyamides can be made based on different number of carbon atoms contained in diamine and binary acid or amino acid. Polyamide has dozens of varieties, among which polyamide-6, polyamide-66, and polyamide-610 have the widest application. PA features good overall properties, including mechanical property, heat resistance, abrasion resistance, chemical resistance, and self-lubrication, as well as low frictional coefficient and a certain fire resistance. Easy to machine, it is applicable to glass fibers and other padding to enhance modification, improve performances and expand scope of application.

[/col]

[col span=”6″ span__sm=”12″]

Purpose and Application Scope

This kind of products have wide application and can play an important role in replacing metals like steel, iron and copper with plastics. As an important engineering plastic, casting nylon is extensively used to replace copper and alloys for wear parts of mechanical equipment. Nylon is applicable to manufacturing wear parts, transmission structural parts, household appliances, auto parts, screw rod stopping mechanical parts, chemical machinery parts, chemical equipment.

Turbines, gears, bearings, impellers, cranks, instrument boards, drive shafts, valves, blades, screw rods, high pressure gaskets, screws, nuts, seal rings, shuttles, sleeves, and shaft sleeve connectors can all be made of polyamide instead of metals like copper. Featuring no toxicity, light weight, good mechanical strength, abrasive resistance and good corrosion resistance, polyamide is widely used to manufacture bearings, gears, pump blades and other parts. The silk from polyamide fusion has very high strength and is mainly used for synthetic fibers and as surgical sutures.

[/col]

[/row]

[/section]

[section]

Advantages and Disadvantages of Nylon

[row]

[col span=”6″ span__sm=”12″]

Advantages:

1.Nylon features high mechanical strength, high toughness, high tensile strength and compressive strength. Its tensile strength is higher than metal and its compressive strength is as high as metal but its rigidity is lower than metal. The tensile strength is close to yield strength and more than one time higher than ABS. It has good absorption for impact and stress vibration, with impact strength much higher than common plastics and higher than acetal resin.

2.Nylon has outstanding fatigue resistance, and products made of nylon can remain its original mechanical strength after multiple times of flexion. PA is often used in the occasions with very obvious periodic fatigue effects such as escalator handrails and new types of plastic rims for bicycles.

3.High softening point and heat resistance (For example, nylon with high crystallinity such as nylon 46 has a high thermal deformation temperature, and can be used at 150 ℃ for a long time. After glass fibre reinforcement, PA66 has a high thermal deformation temperature up 250 ℃.)

4.It has smooth surfaces, a small frictional coefficient and good abrasive assistance. When functioning as active mechanical components, it has self-lubrication, low noise, no need for lubricant when the abrasive effect is not very high. If lubricant is needed indeed to reduce abrasion or help heat dissipation, either water-oil or grease can be selected. Therefore, drive parts made from nylon can have long service lives.

5.It has corrosive resistance, good alkali resistance and resistance against most salt solutions, as well as resistance against weak acids, engine oil, gasoline, polycyclic aromatic hydrocarbon compounds and common solvents. It has aromatic compound sluggishness, low strong acid resistance and low oxidizing agent resistance. It withstands the corrosion from gasoline, oil, fat, alcohol, and weak bases. It can be used as packing materials of lubricating oil and fuel.

6.It has self-extinguishment, no toxicity, no odor, good weatherability, sluggish to bioerosion, as well as good bacterium and mildew resistance.

7.It has good electrical properties, including electrical insulating property. Nylon has a high volume resistance and high breakdown voltage resistance and can be used as power frequency insulating materials. It has good electrical insulating property even in a highly humid environment.

8.Products made from nylon feature light weight, ease to dye and shape.

[/col]

[col span=”6″ span__sm=”12″]

Disadvantages:

Poor hydroscopicity and poor dimensional stability

Poor low temperature resistance

Poor antistatic property

Poor heat resistance

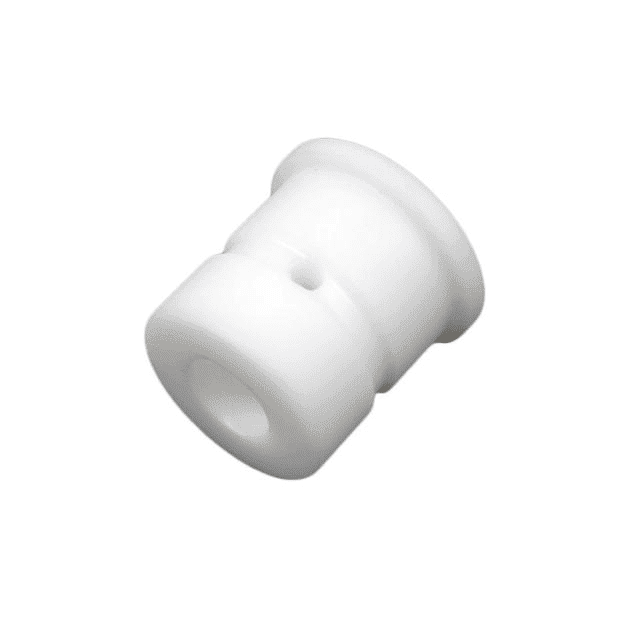

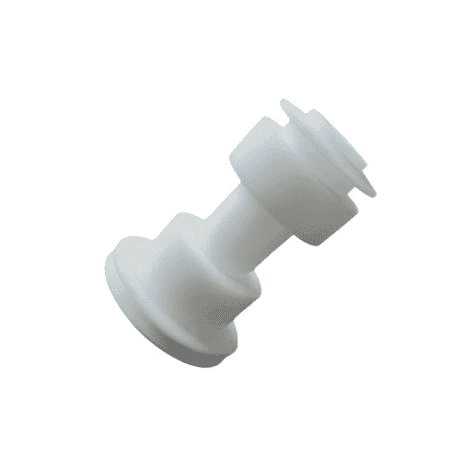

[ux_image id=”2340″ image_size=”original”]

[ux_image id=”2341″ image_size=”original”]

[/col]

[/row]

[/section]

[section]

[row]

[col span__sm=”12″]

Machining Difficulties and Solutions of CNC Turning for Nylon

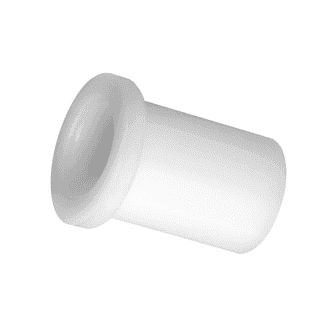

The custom CNC turning nylon bush is made from nylon 66 featuring high toughness, low strength and high volatility. As the turning margin reduces, the strength of the small circular hole decrease gradually. When machining is performed for almost a full circle, both the strength and the wall thickness are the lowest. At this time, elastic deformation tends to occur very much when the workpiece is subjected to the turning force from the cutter. Clamping method consideration: The nylon bush has a out diameter of 12 mm, an allowance of +0.02. Because the allowance is small, the nylon bushes have poor outer diameter consistency in batch production. A tooling fixture needs to be designed which not only guarantees clamping location degree of the nylon bushes but also reduces their clamping deformation. Judging from the fracture process of scraps during machining, elastic deformation and plastic deformation are about to occur to the workpiece. Friction occurs between the cutter rear and the machined surface of the nylon bush and also when the cutter moves through scraps. Both the deformation and the friction consume most of the CNC lathe’s power. During turning, every tooth of the cutter is subjected to two cutting component forces, from the circular blade (radial force+tangential force) and the end face blade (axial force). The maximum cutting force value is determined by the former. At last, cutting plastics is similar with cutting the aluminum alloy, requiring very sharp cutters, a large relief angle and a very large anterior angle. Both the front and back surfaces of the cutter need to be well polished as smooth as possible. Compared to aluminum alloy machining, the cutter movement cannot be too slow, or the plastic will melt.

[row_inner]

[col_inner span=”6″ span__sm=”12″]

[ux_image id=”2342″ image_size=”original”]

[/col_inner]

[col_inner span=”6″ span__sm=”12″]

[ux_image id=”2343″ image_size=”original”]

[/col_inner]

[/row_inner]

[/col]

[/row]

Which is easier to machine, nylon or metal?

I believe many people don’t know the answer to this question. For most custom CNC turning parts manufacturer, nylon is easier to machine. However, every custom CNC turning parts manufacturer with experience or even rich experience knows that whether nylon is easy to machine also depends on the accuracy required by the customer. High accuracy comes with deformation and melting, which can not be well controlled by a custom CNC turning manufacturer with insufficient experience.

[/section]

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569