Description

Application fields of the lining part

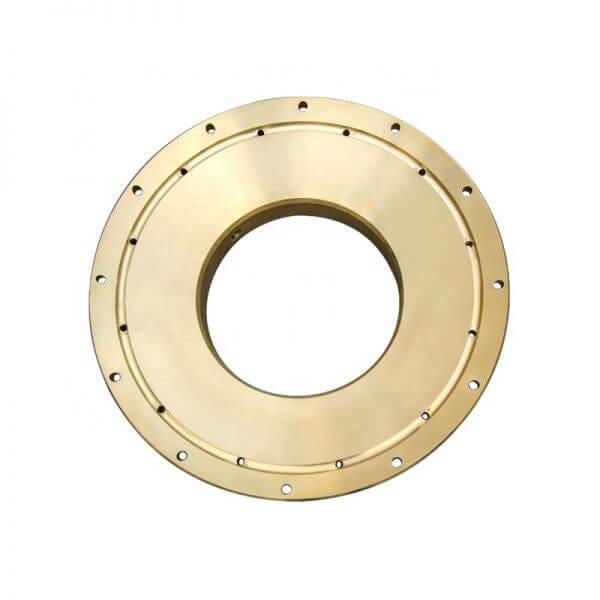

The lining part applies to packing machinery, textile machinery, mining machinery, metallurgical machinery, printing machinery, tobacco machinery, forging machinery, various machine tools and interchangeable mechanical drive coupling, including belt pulleys, chain wheels, gears, propellers, large fans, and other various couplings. Featuring large torque, high precision, easy assembly and disassembly, simple operation, good positioning, reduced scrappage of mated shafts and hubs, re-usability, and no mating surface damages, it is the ideal and most economical selection currently.

Key technologies of the lining

1. The allowances for different sections of a lining is +0.018 – 0.09, with upper deviation and requiring the adapter sleeve’s taper angle difference to be only large. This means that the big end the the taper must coordinate to contact but the small end allows a small amount of clearance. With poor taper hole coordination, the mating self-aligning roller bearing will have a single raw of rollers subjected to forces, which leads to unstable operation, big vibration, loud tone, tendency of looseness, and a short bearing service life. The taper angle difference of a high precision adapter sleeve should be ≤0.005, with a mating contact area not less than 90% guaranteed.

2. The radial play eccentricity of the outer conical surface of an adapter bushing to the inner hole (commonly called wall margin) must be high precision. Otherwise, the rotating shaft produces a centripetal force due to the fair amount and fails for bumping operation with big vibration and a loud tone. The ideal state is 0 wall margin. According to international standards, the dimensional section of a bearing with a maximum inner diameter of below 65 is about half of its maximum standard group clearance and 1/10 of the maximum clearance value of grade C precision. Therefore, the adapter sleeve products up to international standards cannot be used for fine large-load bearing mating.

3. The adapter sleeve’s outer conical surface and inner hole surface must have good linearity, that is good form and location tolerance and high cylindricity precision. This is not specified in national standards, and any single sectional dimension within the allowance range is qualified. This leads to loose control of the linearity of the formed outer conical surface. Especially during cut-in grinding of outer conical surface machining, if the blank has poor linearity itself and the grinding wheel gives poor correction, the surface linearity will not be high. Common companies do not have contourgraphs for inspection. Therefore, this is a big product problem in the adapter sleeve industry of China, which seriously affects mating precision and mating stability and leads to poor bearing functions.

4. The lock nut axially moves and squeezes the bearing lining’s end surface to compress the internal taper between the adapter sleeve and the bearing’s inner hole. In this way, the mating bearing for the screw-threaded coupling function of an adapter sleeve fixes the bearing to the rotating shaft. Therefore, the bearing nut must be in good coordination with the adapter bushing’s threads, meeting the requirements of national standards for common threads.

Call Us Today! (+86) 188-2253-7569

Call Us Today! (+86) 188-2253-7569