China dominates automotive metal stamping, crucial for industries like automotive and aerospace.

Discover the “Top 10 Automotive Metal Stamping Manufacturers in China” known for precision, quality, and innovation.

Explore where tradition meets technology, blending state-of-the-art facilities with skilled artisans.

Whether you’re an expert or a newcomer, this guide navigates China’s dynamic metal stamping industry.

Each featured manufacturer excels in unique specialties. Uncover their strengths in this competitive field.

Gain insights to select the perfect automotive metal stamping parts manufacturer for your needs. Embark on this journey into precision manufacturing, where top Chinese manufacturers reshape the landscape, meticulously metal parts manufacturing.

Also Read:

- Best China Metal Stamping Parts Manufacturers 2024 – Learn more about metal stamping parts manufacturers for different industries.

1. Yijin Solution

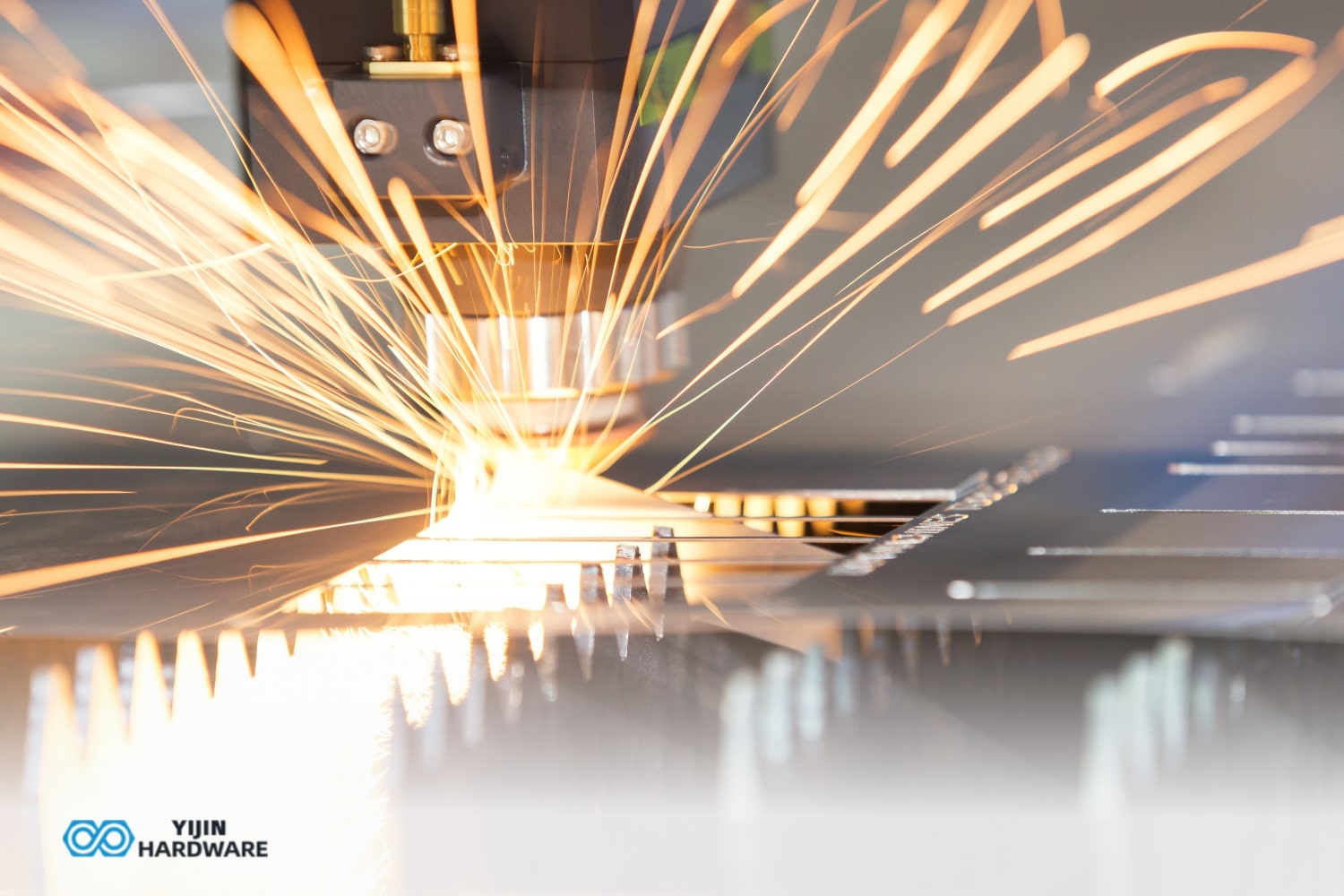

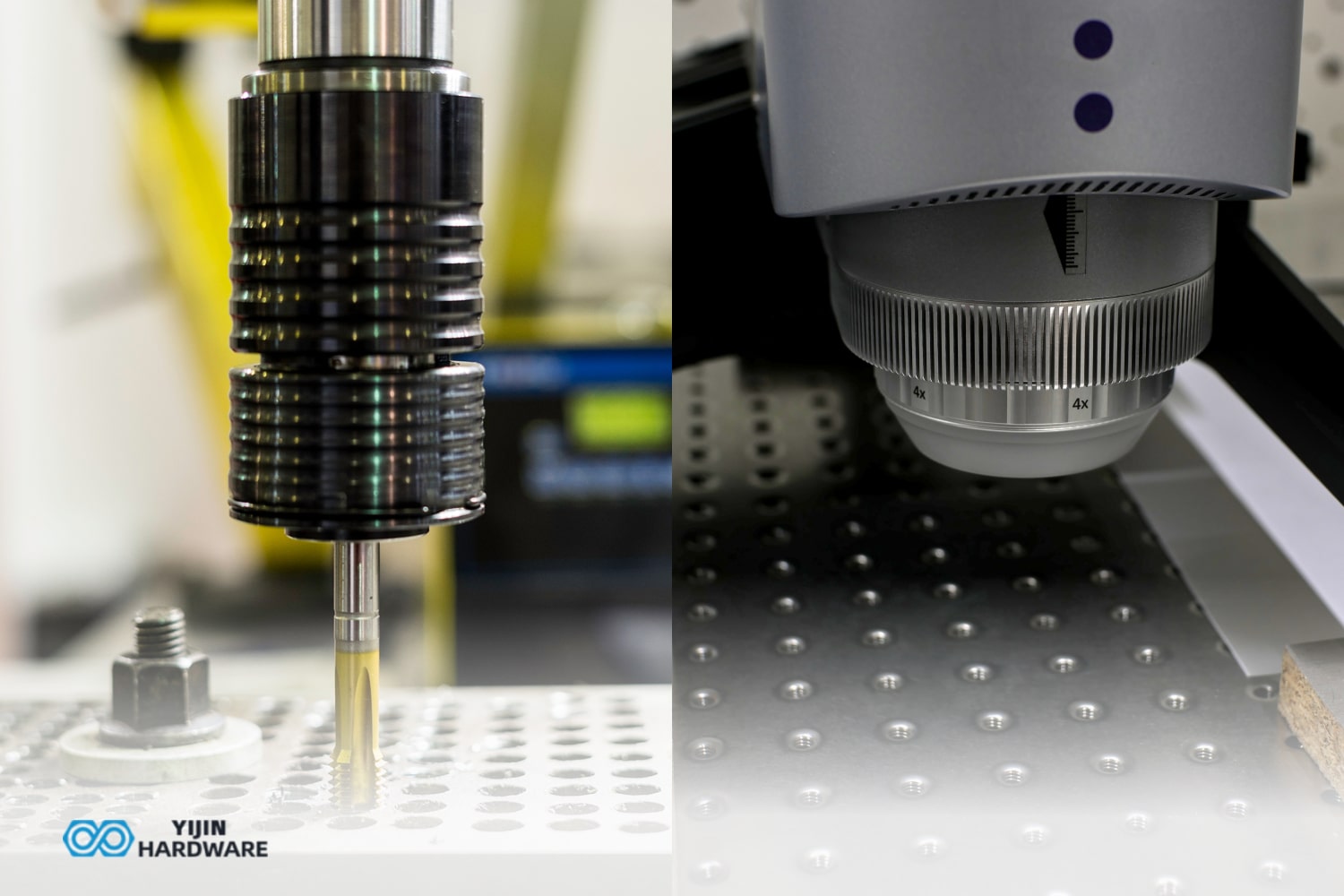

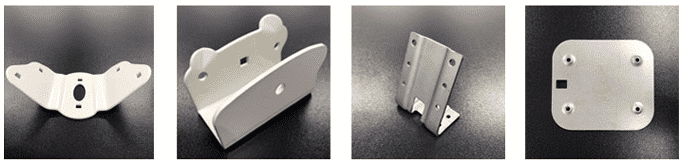

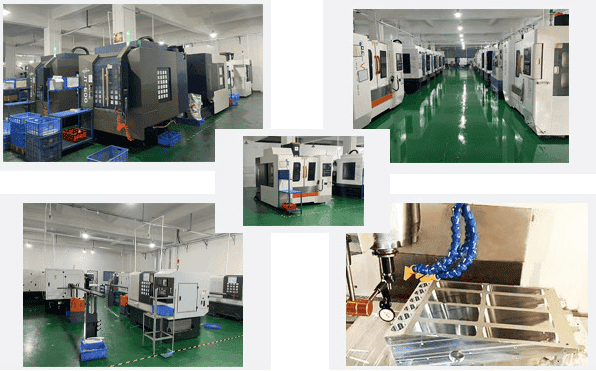

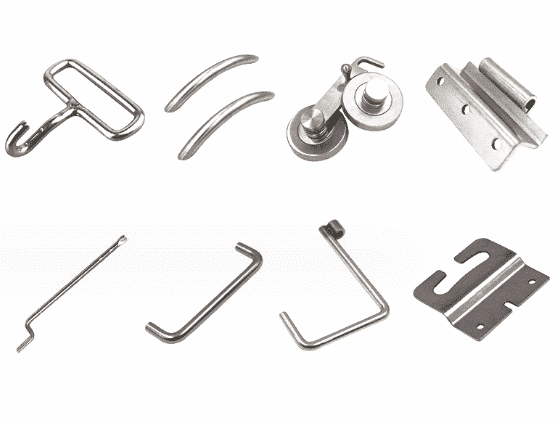

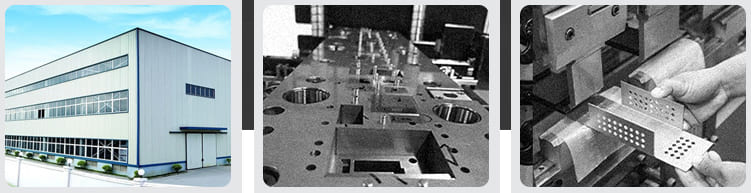

Founded in 2003 in Shenzhen, China, Yijin Solution is an experienced and renowned metal stamping parts manufacturer.

Specializing in precision metal stamping, sheet metal fabrication, and CNC machining, they work with materials like steel, aluminum, and brass.

With its own mold department, which can design and manufacture various metal stamping molds very quickly.

Their services extend to sheet metal fabrications services (including laser cutting servics, bending services, welding, and assembly services) and CNC machining (covering turning, milling, planing, drilling, and punching).

Also, they offer a wide range of finishing choices, including painting, plating, and powder coating.

With their experienced engineers and technicians, they guarantee precise part fabrication.

Over a decade, it has become a leader in precision metal stamping and die mold processing in China.

Partnering with them offers many benefits, including their extensive industry expertise, cutting-edge equipment, streamlined production, diverse finishing capabilities, and a dedicated team of engineers and technicians.

2. Jiaxin Precise Metal

Jiaxin (Xiamen) Precise Metal Co., Ltd. is a Hong Kong-funded high-tech enterprise established in 1998 in Xiamen, China.

Specializing in electronic product accessories, including hardware stamping and precision die cutting.

With dust-free workshops meeting high-grade standards, the company operates over 7,500 square meters of facility.

It has a registered capital of RMB16.88 million, over 150 employees, and an annual turnover exceeding RMB129 million.

Key to its success are advanced production facilities, testing equipment, technical experts, and partnerships with manufacturers like Baosteel and Chinalco Luoyang Copper, ensuring competitive raw material costs.

Their product range includes electronic accessories, hardware stamping parts, and precision die-cutting parts, serving various industries globally.

The company maintains stringent quality control with ISO9001:2000 certification and a team of experienced engineers and technicians.

For exceptional metal stamping parts, look no further than Jiaxin (Xiamen) Precise Metal Co., Ltd.

Their blend of expertise, cutting-edge facilities, and abundant resources is your answer to reliable solutions.

3. Dongguan Fortuna

Established in 2003, Dongguan Fortuna also specializes in precision metal stamping parts manufacturing.

Their 16,000-square-meter facility employs 200 professionals and offers a comprehensive range of services, including precision CNC processing, injection molding, and product assembly.

With ISO14001:2015 and IATF16949:2016 certifications, they maintain high-quality standards.

Their products find applications in various sectors, from home appliances and communication equipment to auto parts, new energy vehicles, and aviation.

The company has gained global recognition, exporting to countries such as Japan, the USA, Germany, and more.

It boasts impressive production capabilities, with 63 stamping machines with tonnages of 25 to 200 tons, achieving speeds of up to 600 times per minute.

Their CNC machinery, including 5-axis and 6-axis machines, processes materials precisely, operating at a 70% utilization rate.

Their strengths lie in its 8-member R&D team, responsive after-sales service, and the ability to produce high-precision progressive dies.

With a focus on quality and efficiency, Dongguan Fortuna is a trustworthy partner in precision metal stamping.

4. KDM Steel

KDM Steel, a seasoned player in metal stamping part manufacturing, combines over a decade of experience to deliver the best precision components.

Their unwavering commitment to top-tier metal stamping sets them apart as the go-to choice for precision engineering.

They offer a diverse product range catering to various industries, showcasing their versatility and ability to meet a range of customer demands.

Also, they provide rapid custom design services with 2D/3D drawings in a day and fully realized samples in three days.

Quality is paramount at KDM Steel, using cutting-edge techniques and premium materials.

They hold ISO 9001 certification to emphasize their dedication to quality standards.

Operating within a spacious 3000-square-meter facility equipped with modern machinery and skilled technicians, it excels in delivering top-notch stamped parts.

They also offer certified water and dustproof metal stamping parts for reliable performance in challenging environments.

KDM Steel’s relentless pursuit of excellence has earned them national invention and practical patents, reflecting their commitment to innovation in metal stamping parts manufacturing.

5. Feng Yu

Feng Yu is another foremost Chinese custom metal stamping parts manufacturer since 1971.

It excels in precision metal processing with nearly five decades of experience.

They supply critical components for industrial equipment, offering a one-stop service from concept to surface treatment.

Their reputation is built on material expertise, advanced technology, stable quality, and consistent delivery.

Notably, they stand out with state-of-the-art overseas equipment, a dedicated team, and a focus on efficiency. It ensures customer satisfaction through flexible solutions.

Specializing in die design and manufacturing, especially in the automotive and medical sectors, they transform sheet metal into intricate parts using stamping presses capable of two and three-dimensional operations.

Careful planning based on critical parameters and secondary processes enhances results. Their expertise expedites development, mitigates risks, and facilitates innovation.

With strategic branches, they efficiently serve a diverse clientele, making them a pioneering force in metal stamping and die supply, known for excellence and customer success in China and beyond.

6. Tenral

Tenral, a trusted CNC machining manufacturer specializing in metal stamping parts, boasts a rich two-decade history of excellence.

They excel in efficiently producing these parts with state-of-the-art machinery, emphasizing precision and effectiveness.

It excels in metal stamping, offering processes like blanking, bending, coining, forming, and piercing with presses ranging from 32 to 200 tons.

Their process incorporates blanking, punching, bending, and forming techniques to ensure top-notch results.

The company maintains high-quality standards aligned with ISO and IAFT requirements. They prioritize customer privacy and do not share information with third parties without consent.

Serving industries like automotive, lighting, construction, and energy, it is trusted by many renowned brands.

Benefits of choosing Tenral include their versatility in producing simple to complex metal stamping parts, in-house custom die development, strict quality control, and ethical handling of intellectual property.

7. MicPro Precision Co., Ltd.

Micpro, as another leader in metal stamping mold production, blends innovation and quality.

Founded by engineers and designers two decades ago, they excel in crafting top-notch mold solutions using advanced technology and premium materials.

Beyond technology and production, it emphasizes collaboration with clients to fully understand their requirements and provide optimal solutions.

This approach has resulted in long-term partnerships and successful projects.

As a forward-thinking company, it is dedicated to innovation, focusing on developing micro-precision stamping molds and hardware solutions to streamline product launches.

Micpro is committed to supporting clients every step of the way, ensuring efficient material procurement and accelerated production schedules, and helping clients bring their innovations to market swiftly.

Proudly made in China, Micpro continues to lead in metal stamping mold production with micro-precision solutions and unwavering client support.

8. Qingdao Hailong Machinery Group Co., Ltd.

Qingdao Hailong Machinery Group Co., Ltd., located in Qingdao, China, is a respected national high-tech enterprise established in 2000.

With over six decades of experience in metal stamping parts manufacturing, they are industry leaders.

They offer a comprehensive range of services, from designing and making precision metal stamping dies to producing excellent metal parts with strict quality control.

Their metal stamping parts find applications in body panels, door panels, bumpers, grilles, wheels, engines, transmission, and electronic components.

They serve diverse sectors such as automotive, construction, agriculture, medical, and electronics, showcasing their adaptability.

Their modern manufacturing facility is equipped with advanced CNC machines, stamping presses, and welding machines, supported by a skilled team of engineers and technicians.

Quality is central, with rigorous inspections to meet high standards. Exceptional customer service reinforces their commitment to excellence.

In short, Hailong Group Co., Ltd. is a trusted metal stamping parts manufacturer, offering a full range of services and unwavering quality.

9. Beijing Oriens

Beijing Oriens Technology Co., Ltd. is a respected player in metal stamping parts manufacturing for various OEM engineers.

Quality is the top priority for OEM engineers, but surprisingly, surveys reveal a significant concern: “On-Time Delivery.”

They prioritize this concern, considering it a vital performance indicator.

Driven by their commitment to meet customer expectations and eliminate hidden costs associated with late deliveries, they maintain a vigilant approach to on-time delivery.

It excels with an impressive on-time delivery performance, even in challenges like material shortages, schedule changes, or weather delays.

Their proactive approach sets them apart, anticipating customer needs and ensuring dependability.

Beijing Oriens Technology Co., Ltd. offers more than just metal stamping parts; they provide “The Perfection Advantage.”

Their unwavering focus on on-time delivery, excellence, and competitive pricing makes them a compelling choice for OEM engineers in the metal stamping parts manufacturing sector.

10. Mulan Manufacturing Group

Mulan Manufacturing Group, the last but not least Chinese manufacturing leader with 18+ years of experience, specializes in custom metal stamping parts.

They operate a well-equipped metal stamping workshop with progressive stamping machines, hydraulic presses, and CNC punching machines to create various components.

Mulan MFG offers different stamping techniques:

- Progressive stamping for intricate high-volume parts.

- Hydraulic pressing for versatile applications.

- CNC punching for precise small features.

Their experienced metal stamping engineers assist in design, production, material selection, tooling, and quality control.

For reliable and seasoned metal stamping manufacturing, consider Mulan MFG, with its extensive experience and skilled team.

Conclusion

In summary, China boasts a robust metal stamping industry with a diverse range of top manufacturers.

This article has highlighted the top 10 players in the field, each renowned for their quality, technology, and adaptability to various industries.

Whether you’re in automotive, electronics, or aerospace, these manufacturers offer tailored solutions.

However, conducting thorough research based on your specific requirements, including production capabilities, certifications, and customer feedback is essential.

China’s metal stamping sector remains dynamic and innovative, making it a valuable resource for businesses seeking reliable metal components.

Selecting a suitable manufacturer from this list can elevate product quality, streamline your supply chain, and bolster your industry standing.

Explore the above options today to tap into the potential of China’s top metal stamping parts manufacturers.

(+86) 188-2253-7569

(+86) 188-2253-7569