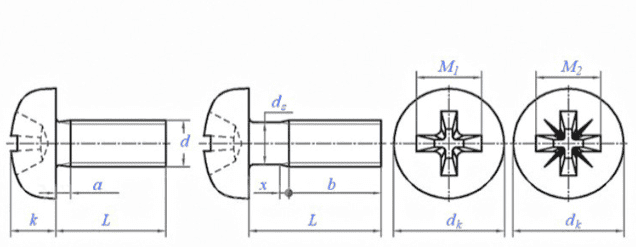

The term “bolt” refers to any mechanical fastening with a threaded shaft. Mechanical fasteners having threaded shafts, like bolts, are a near relative of screws.

The holes in the two pieces are positioned so that the fastener may be placed through them.

Some definitions consider the object’s intended purpose to determine whether it is a bolt or a screw.

The bolt is threaded through the unshielded holes in the various components, and a nut is then tightened onto the bolt to generate a clamping force and prevent the bolt from moving axially.

Threaded fasteners in one component allow a screw to be threaded through an evacuation hole in another component. The strength of the bolts is indicated by a pair of integers separated by a point.

In this post, YIJIN Hardware engineers will share you with the different types of bolts.

Types of Bolts

There are different types of bolts:

Following are brief introductions of each of these common types of bolts and a description of their important characteristics and uses.

1. Anchor Bolt

Attaching structural and non-structural components to concrete slabs is a common practice that calls for the usage of anchor bolts.

Anchor bolts, steel plates, or stiffeners manufactured by reliable bolts and nuts suppliers are all viable options for making the connection. In addition to tensile stresses, anchor bolts can also transfer shear loads.

Steel columns fastened to a reinforced concrete base are a good metaphor for the bond between various structural components.

Facade systems attached to reinforced concrete walls are a frequent example of non-load-bearing elements affixed to structures.

Recommended: Top 10 Bolts And Nuts Manufacturers In China

2. Arbor Bolts

For usage with power instruments, especially miter saws, an arbor bolt is required. These types of bolts fasten the blade firmly into place and ensure the instrument won’t fall apart.

The arbor is the shaft that holds the blade. The diameter of the arbor, where the blade is connected, is 5/8″ on all 10″ American stationary saws.

As opposed to other types of bolts, arbor bolts come fully constructed before delivery. A washer is always affixed to the end of an arbor bolt.

The Arbor bolts are easily identifiable because of the included washer. These types of bolts are distinguished by a pronounced ridge surrounding the recessed design of their heads.

Arbor bolts are usually manufactured in a dark color, often black. They are also produced with reverse threads. To ensure precision and durability, we’ve compiled a CNC material list that can help in selecting the best materials for producing arbor bolts.

An arbor bolt, like other types of bolts, has an inverted tread pattern on the shaft, making it seem to be installed backward.

For the arbor bolt to perform its primary purpose, the reverse thread is crucial.

3. Blind Bolts

As a structural fastener, a blind bolt outperforms a rivet or weld in terms of both strength and flexibility.

They were created to produce a secure bond in situations where using rivets or hex bolts would be too time-consuming or impossible.

Blind bolts were created to address the issue of limited access, which prevents the use of rivets or hex bolts in many situations.

For many years now, blind bolts have been the go-to option for restricted access in industries like manufacturing, construction, and maintenance because of how effective they are.

4. Carriage Bolt

In the context of fastening metal to metal or, more typically, wood to metal, a carriage bolt is a necessary type of Bolt.

An Australian or New Zealander might recognize this fastener type as a washer head screw.

The head of the carriage bolt is flat, and the shank’s cross-section is square right below the head, making it distinct from other bolts.

When the bolt is placed into the square hole in the metal band in this way, it locks itself. Therefore, a single instrument, such as a wrench, may be used to attach the fastener from the other side.

In most cases, carriage bolts have a flat, domed head. There are no threads on the shaft, and its diameter is the same as that of the square’s side.

The carriage bolt’s square head was made to fit into a square hole in the ironwork, allowing it to be used to fasten the plate on each side of a timber beam.

A carriage bolt’s square shape provides adequate traction to prevent rotation, making it a typical fastening method for bare wood.

When the bolt only has to be removed from one side, such as in locks and hinges, the lock bolt is employed.

The carriage bolt cannot be opened from the potentially dangerous side because of its smooth, domed head and the square nut underneath it.

5. Elevator Bolts

Elevator bolts have a slender body and a rounded head, and they are threaded. To prevent the bolt from rotating when the nut is tightened, either a square or ribbed neck can be used.

These types of bolts are employed in confined places with moving elements such as elevators and conveyor belts.

Because of their compact profile, the elevator bolts may be used in tight spaces without causing any obstructions.

6. Eyebolt

A mechanical fastener, an eyebolt has a ring-shaped head on top of a threaded shaft. The purpose of an eyebolt is to fix an eye to a surface so that a line or cable may be run through it and fastened to the anchor.

A lifting eye is often fabricated so that a crane may be mounted to a piece of equipment; these lifting eyes have a specific purpose and are rated for their safe operating load.

A bar with a diameter equal to the nominal thread size is commonly used to create low-strength eyebolts. Precision in manufacturing is essential for such applications, and custom CNC machining service china provide the accuracy required for producing high-quality eyebolts.

The head is made by bending a piece of the bar that is not threaded into a ring. Although suitable for axial stresses, these types of eyebolts are not recommended for off-axis loads.

Welding won’t prevent the opening created when the bar’s end is closed to complete the ring from being a weak spot.

7. Flange Bolts

A flange bolt’s round under-head flange serves as a washer to evenly disperse pressure. Types of bolts with a hex head rather than serrations on the flange are commonly referred to as frame bolts.

Flange bolts, popular in the automobile industry but also used in plumbing and other fields, include a washer-like flange behind the bolt head, which helps to speed up manufacturing while also distributing the clamping load and protecting the mating surface. For applications like connecting a car’s transmission to its engine, custom car parts manufacturing and automotive prototyping services are essential in ensuring the precision and durability of these components.

Use a flange bolt if you require a secure, long-lasting connection between two pieces of a big, confined space. In this sense, the relationship between a car’s transmission and the engine is the most instructive.

8. Hex Bolt

When tightening, the hexagonal head of hex cap screws and hex bolts is ideal. Hex bolts are different from standard bolts since they don’t have a washer under the head or a beveled end and hence need a nut to secure them.

These screws and bolts have several applications in building, fixing machines, and performing routine maintenance.

There is a wide range of hex cap screws and hex bolts available on the market today, each with its own specific size, finish, quality, and material requirements.

9. J-Bolts

An example of a versatile bolt design is the J-shaped J bolt. These types of bolts don’t have bolt heads, but the threaded end may be used with a nut. They see the widespread application in the building trade.

The curved end might serve as an anchor bolt when cast in concrete. The most common places to find them are in roofing and the attachment of walls to concrete.

J bolts may be found at a wide variety of hardware stores and home improvement centers, and you can even purchase special sizes from the companies that make bolts and fasteners.

Depending on their intended use, J bolts can be fabricated from a variety of metals and finished in a number of ways.

If you perform a lot of home improvement jobs, it may be helpful to have a few on hand.

10. Lag Bolts

Although they don’t have a nut slot, lag bolts and lag screws are still considered screw fasteners.

These fasteners are typically used to attach large timber or other items that will be subjected to a tremendous amount of pressure.

It’s important to note that these types of bolts are not the same as the standard wood, self-drilling, or sheet metal varieties.

Lag bolts are considerably larger than standard bolts. Lag bolts typically measure at least an inch in length and 1/4 inch in diameter.

For example, wood screws are utilized when connecting an application using just wood materials. Although these wood screws have coarse threading, it does not extend over their whole length.

11. Machine Bolt

Machine bolts, like hex bolts, are used to fasten two pieces of metal together, however, unlike hex bolts, their heads aren’t chamfered and there is no washer-support surface.

The types of machine bolts are frequently offered with both a hexagonal and a square head.

Misunderstandings arise because machine screws, another type of fastener, are frequently substituted for machine bolts.

Despite being smaller than machine bolts, machine screws have uniform threading over their entire length.

12. Hanger Bolts

A hanger bolt is a double-ended bolt that is commonly used to attach legs to furniture. Hanger bolts are pretty much unsung heroes of hardware.

These nuts and bolts aren’t attractive or flashy, and you probably won’t hear or think about them again. Hanger bolts aren’t flashy like some other kinds of fasteners, but they’re essential to the structure of your house.

Conclusion

“Screw” and “bolt” are sometimes used interchangeably, but the main distinction between the two is that a screw threads directly into a substrate while a bolt goes through it and is caught on the other side by a nut.

[gap height=”58px”]

[blog_posts style=”normal” columns=”3″ columns__md=”1″ ids=”5972,3158,2617″ image_height=”56.25%”]

info@yijinsolution.com

info@yijinsolution.com (+86) 188-2253-7569

(+86) 188-2253-7569