Roughing and finishing are two critical phases in CNC (Computer Numerical Control) machining, which is a manufacturing method used to make accurate and complicated pieces from a variety of materials. Let’s take a deeper look at each stage:

Roughing in CNC Machining

Roughing is the first stage of material removal from a workpiece in CNC (Computer Numerical Control) machining.

It entails swiftly and efficiently removing surplus material to form a rough shape that can be improved further by following procedures.

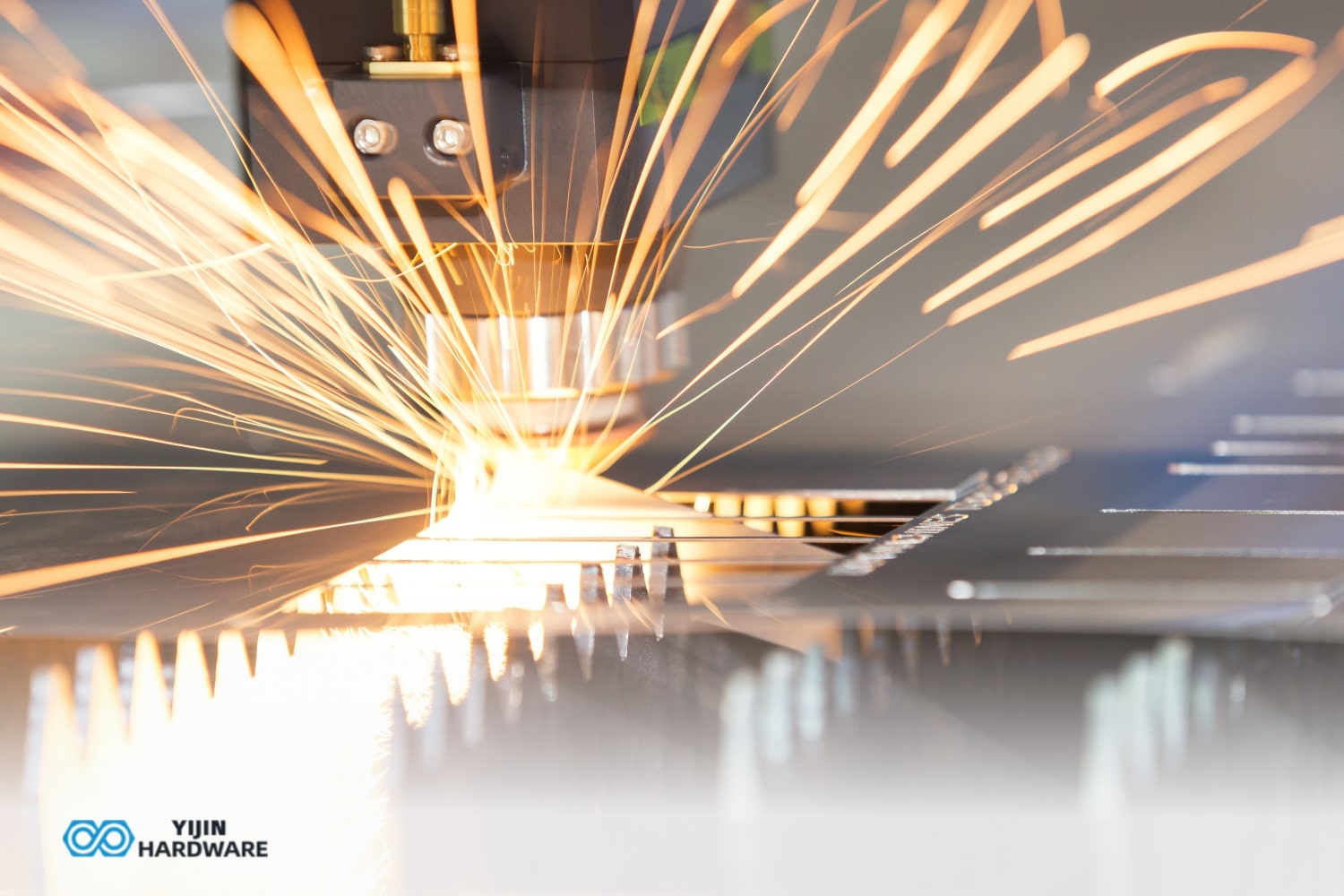

During the roughing process, a cutting instrument, often an end mill or a roughing mill, is used to remove material from the workpiece.

A CNC program directs the tool’s movements depending on the eventual product’s shape and dimensions.

Roughing is often conducted at faster cutting speeds and feeds than finishing activities. This is done to maximize material removal rates while retaining a reasonable tool life.

The idea is to remove material as quickly as possible while leaving adequate stock for future use.

Depending on the intricacy of the item and the material being machined, the roughing process may entail numerous passes.

Each pass removes a set amount of material, progressively lowering the stock to the required level.

The CNC program controls the tool path and cutting parameters for each pass, optimizing the efficiency and accuracy of the roughing operation.

Roughing, in addition to material removal, helps to relieve internal stresses inside the workpiece and reduces the likelihood of deformation during following machining operations.

It ensures that the final product has enough material to achieve the specified dimensions and surface polish.

Overall, roughing is an important phase in CNC machining because it allows for efficient and controlled material removal to provide a rough shape that may be refined further.

The Key Objectives of Roughing Are:

- Material removal: Roughing removes the majority of the excess material, transforming the raw workpiece into a shape that closely resembles the final part.

- Time efficiency: Roughing aims to be fast, removing material at high speeds to reduce overall machining time.

- Tool longevity: Roughing involves using more robust tools that can withstand the high cutting forces generated during material removal.

Roughing typically utilizes larger cutting tools with fewer flutes (cutting edges) to accommodate higher chip loads and facilitate efficient material removal.

Cutting parameters such as cutting speed, feed rate, and depth of cut are usually adjusted to higher levels during roughing to optimize material removal rates.

Considerations For Roughing In Machining

There are several significant factors to consider when roughing in machining. Roughing is the technique of swiftly and efficiently removing large amounts of material to produce the required shape and size of the item before proceeding to the finishing procedures.

When roughing in machining, there are several important things to consider.

- Material Removal Rate: The fundamental goal of roughing is to remove the material as rapidly as possible. As a result, optimizing the material removal rate while preserving process stability is critical. If we need to achieve efficient chip evacuation and reduce cutting time then we need to select the correct cutting parameters, such as cutting speed, feed rate, and depth of cut.

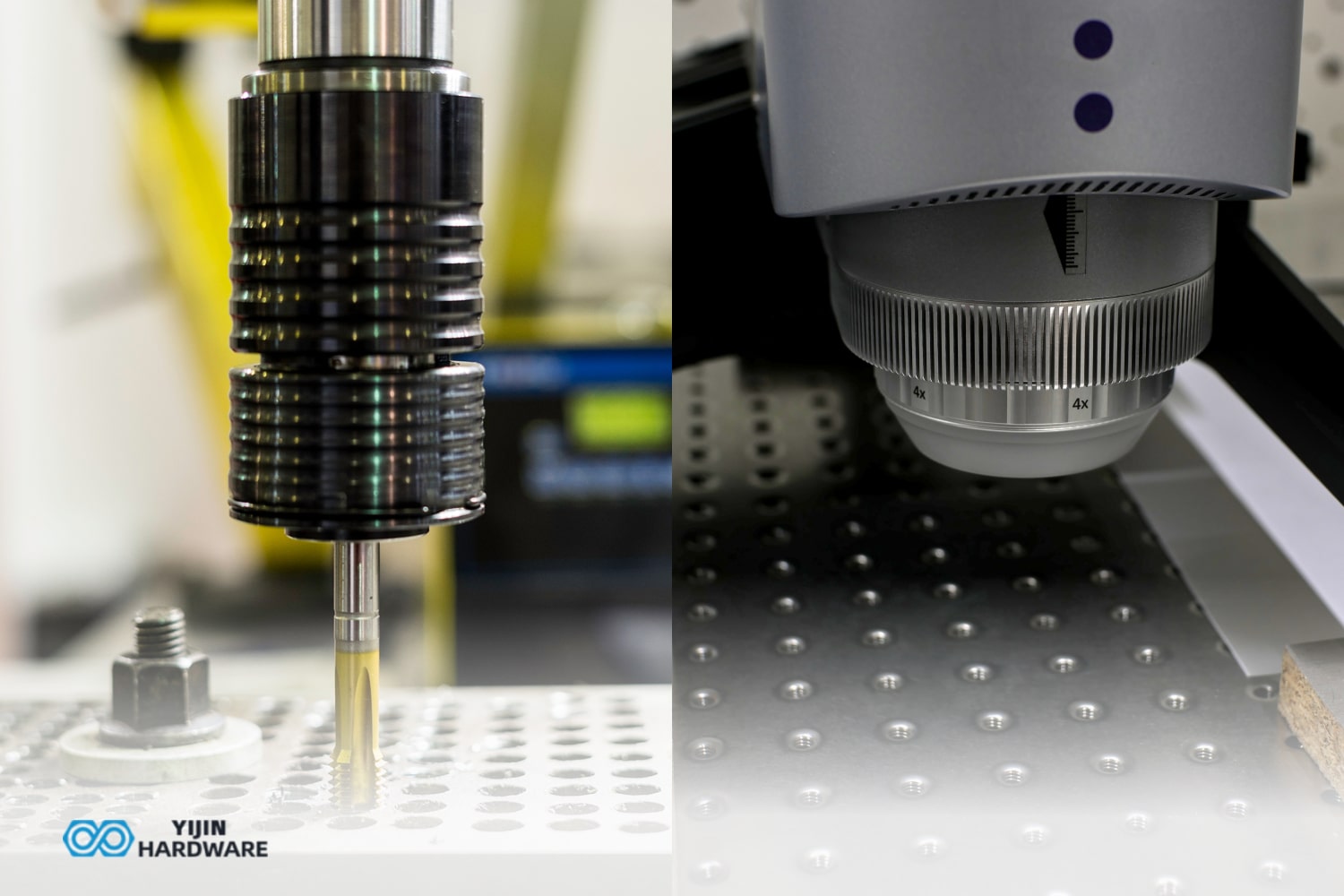

- Tool Selection: Choosing the right cutting tool is crucial for roughing operations. Typically, roughing involves the use of solid carbide or high-speed steel (HSS) end mills, roughing end mills, or indexable milling cutters. The tool should be capable of withstanding the high cutting forces and provide adequate rigidity and heat resistance.

- Cutting Parameters: Selecting appropriate cutting parameters is essential for successful roughing. The cutting speed, feed rate, and depth of cut should be balanced to ensure efficient material removal while avoiding excessive tool wear or breakage. Depending on the material being machined, machine capability, and equipment, optimal parameters may differ.

- Chip Control: Effective chip control is necessary to prevent chip clogging, tool damage, and poor surface finish. Proper chip evacuation can be achieved by selecting appropriate cutting parameters, using chip breakers on the cutting tool, employing coolant or lubrication, and employing chip evacuation methods such as through-tool coolant or chip conveyors.

- Tool Life and Cost: Roughing operations can be demanding on cutting tools due to the high material removal rates involved. Balancing tool life and cost is essential. It may be more cost-effective to use cheaper or less durable tooling for roughing operations, reserving high-performance tools for finishing operations where surface finish and dimensional accuracy are critical.

By considering these factors, manufacturers can optimize the roughing process, reduce machining time, minimize tool wear, and achieve the desired part shape efficiently, setting the stage for subsequent finishing operations.

Finishing in CNC Machining

Finishing is the final stage of the CNC machining process in which the surface of a machined component is modified to satisfy specific requirements such as appearance, smoothness, and dimensional correctness. It entails a variety of techniques and processes targeted at refining the workpiece to reach the desired end product.

Here are some common methods used for finishing in CNC machining:

- Deburring: After the machining process, burrs or sharp edges may be left on the workpiece. Deburring involves removing these imperfections using tools like deburring blades, brushes, or tumbling machines.

- Surface Smoothing: To achieve a smooth surface finish, CNC machined parts often undergo processes like sanding, grinding, or polishing. These techniques eliminate rough spots, machining marks, or surface irregularities, resulting in a more refined appearance.

- Surface Coating: Applying coatings can enhance the functionality and aesthetics of CNC machined parts. Common coating methods include electroplating, powder coating, anodizing, or painting. These coatings can provide corrosion resistance, improved durability, and attractive finishes.

- Precision Machining: In some circumstances, extra machining operations may be required to reach the appropriate dimensions or tolerances. This can involve secondary CNC operations such as reaming, tapping, or boring to ensure precise measurements and fit. Learn more: The Difference Between Drilling, Boring, Broaching And Reaming?

- Assembly and Finishing Operations: CNC machined parts may require additional assembly or finishing operations, such as attaching fasteners, adding inserts, or integrating other components. These final steps complete the manufacturing process and prepare the parts for their intended use.

Overall, finishing in CNC machining is crucial for achieving the desired product quality and functionality.

It ensures that the machined parts meet specific design requirements, aesthetics, and performance standards, making them suitable for their intended applications.

The Key Objectives of Finishing in CNC Machining:

- Surface Finish: One of the primary objectives of finishing is to achieve the desired surface finish on the machined part. This involves reducing or eliminating surface imperfections such as burrs, roughness, tool marks, and scratches. The surface finish can be crucial for parts that require an aesthetic appeal, and functionality, or specific performance requirements.

- Dimensional Accuracy: CNC machining aims to produce parts with precise dimensions as specified in the design. Finishing techniques aid in ensuring that the final dimensions are within the tolerances specified. This involves removing any excess material, adjusting any discrepancies, and achieving the correct size and shape of the machined part.

- Part Integrity: Finishing also focuses on maintaining the structural integrity of the part. It involves inspecting the part for any potential defects, such as cracks, porosity, or incomplete machining. Additionally, finishing processes may include stress relieving or heat treatment steps to enhance the part’s durability and mechanical properties.

- Deburring: Burrs, which are unwanted rough edges or projections, can be formed during the CNC machining process.What Caused The Burr Formed In CNC Machining? Removing these burrs is crucial to ensure the safety of handling the part, prevent damage to other components, and achieve the desired fit and function of the assembly. Deburring is typically performed as part of the finishing process.

By achieving these objectives, finishing in CNC machining ensures that the final parts meet the required quality standards, functional requirements, and customer expectations.

Considerations For finishing In Machining

When it comes to finishing in machining, there are several important considerations to ensure high-quality surface finishes, dimensional accuracy, and overall part integrity.

Here are some roughing concerns for machining:

- Surface Finish Requirements: The first consideration is to understand the specific surface finish requirements for the part. Surface finish can be specified in terms of roughness, waviness, or specific texture requirements. The chosen finishing processes and parameters should be capable of achieving the desired surface quality.

- Tool Selection: Choosing the proper cutting or finishing tool is critical for getting the desired surface finish. Finishing tools such as end mills, grinding wheels, or polishing stones may have different characteristics and abrasives to suit different materials and surface finish requirements.

- Cutting Parameters: The cutting parameters used during finishing operations should be carefully controlled. Factors such as cutting speed, feed rate, and depth of cut may need to be adjusted to achieve the desired surface finish while minimizing the risk of tool wear, chatter, or part deflection.

- Tool Wear Monitoring: Monitoring tool wear during finishing operations is important to maintain consistent surface finish quality and dimensional accuracy. If the tool becomes worn or dull, it can negatively impact the surface finish or cause deviations from the desired dimensions. It is vital to inspect and replace worn tools on a regular basis.

- Coolant or Lubrication: Proper coolant or lubrication can aid in achieving better surface finishes during machining. It helps to dissipate heat, reduce friction, and improve chip evacuation. The selection and application of the coolant or lubricant should consider the material being machined and the specific finishing process employed.

- Surface Inspection: Regular surface inspection during finishing operations is essential to monitor the quality of the surface finish and identify any defects or deviations from the desired specifications. This may involve visual inspection, using metrology tools such as profilometers or coordinate measuring machines (CMMs), or employing non-destructive testing techniques.

By considering these factors, manufacturers can optimize the finishing process, achieve the desired surface finish and dimensional accuracy, and ensure the overall quality and functionality of the machined parts.

Differences between Roughing and Finishing

| Parameter | Roughing | Finishing |

| Goal | The rough pass’s goal is to remove the majority of excess material from the workpiece in each pass. | The goal of the finish pass is to increase surface quality, dimensional accuracy, and tolerance. |

| Feed Rate | Higher feed rate | Very low feed rate |

| Material Removal Rate | The material removal rate (MRR) is high. | The material removal rate (MRR) is low. |

| Surface Finish | Surface roughness increases following a harsh pass, resulting in a poor surface finish. | Surface roughness is low after the finish pass, indicating that the surface finish is good. |

| Dimensional Accuracy | It is not capable of providing great dimensional accuracy and close tolerance. | It has the ability to deliver great dimensional precision and close tolerance. |

Conclusion

In conclusion, roughing and finishing are two essential stages in CNC machining that contribute to the overall quality and functionality of machined parts.

Roughing focuses on rapid material removal, efficiently shaping the part while considering factors such as material removal rate, tool selection, cutting parameters, machine rigidity, chip control, work holding, toolpath strategy, and tool life. It sets the foundation for subsequent finishing operations by efficiently removing excess material.

Finishing, on the other hand, aims to achieve the desired surface finish, dimensional accuracy, and part integrity.

Considerations for finishing include understanding surface finish requirements, selecting appropriate tools, controlling cutting parameters, choosing optimal machining strategies, monitoring tool wear, employing coolant or lubrication, ensuring proper fixturing and work holding, conducting a surface inspection, and performing post-processing as needed.

By carefully considering these factors and optimizing the roughing and finishing processes, manufacturers can produce high-quality machined parts that meet the required specifications, enhance performance, and satisfy customer expectations.

(+86) 188-2253-7569

(+86) 188-2253-7569