Swiss Machining Service | Precision Turning, CNC Machining Solutions

UHMW-PE, or ultra-high molecular weight polyethylene, is a type of plastic known for its great durability and low friction properties. It is widely used in various industrial applications due to its high impact strength and abrasion resistance. At Yijin Hardware, we are experienced in providing expert CNC machining services that produce custom UHMW parts tailored to meet your needs.

- ⬤Service

- ⬤Your Details

- ⬤Submit

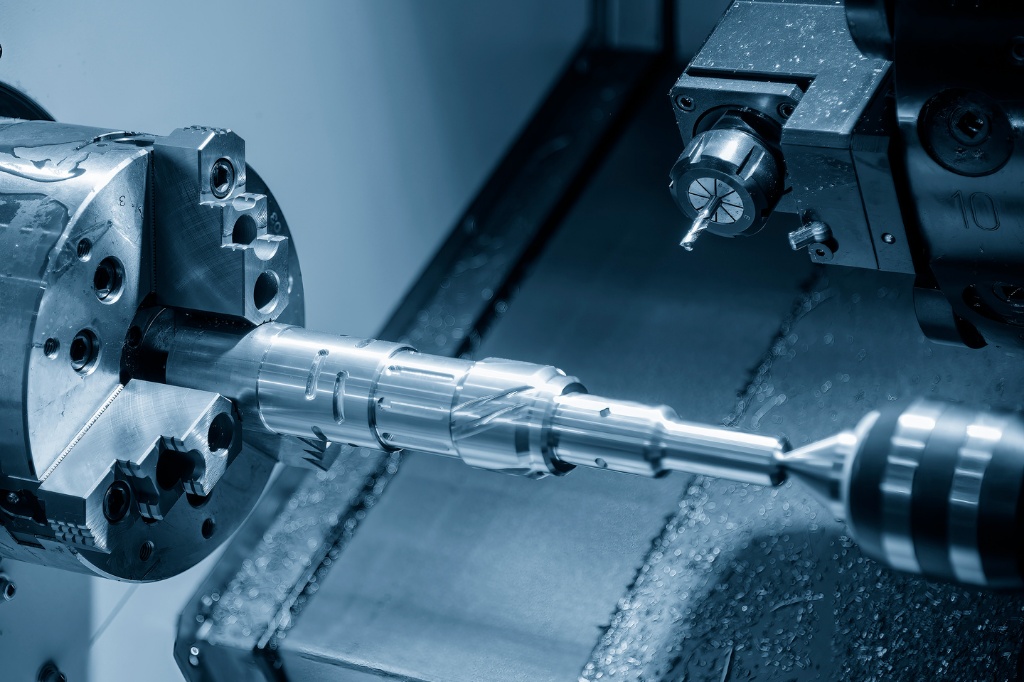

What is Swiss Machining?

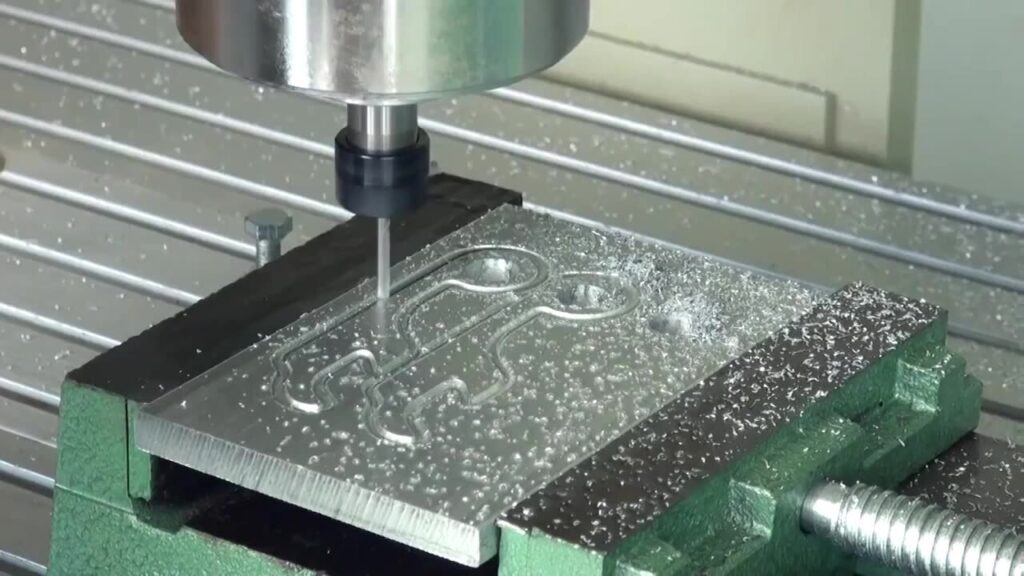

Swiss machining refers to a method of manufacturing that originated in Switzerland, primarily used for producing small, high-precision parts. It uses a Swiss-type lathe, which allows for the continuous rotation of the workpiece while cutting tools move along multiple axes. This setup enables the creation of complex shapes and features in a single operation, significantly reducing cycle times and enhancing productivity.

Yijin Hardware’s Swiss Machining, Precision Turning, and CNC Machining Solutions

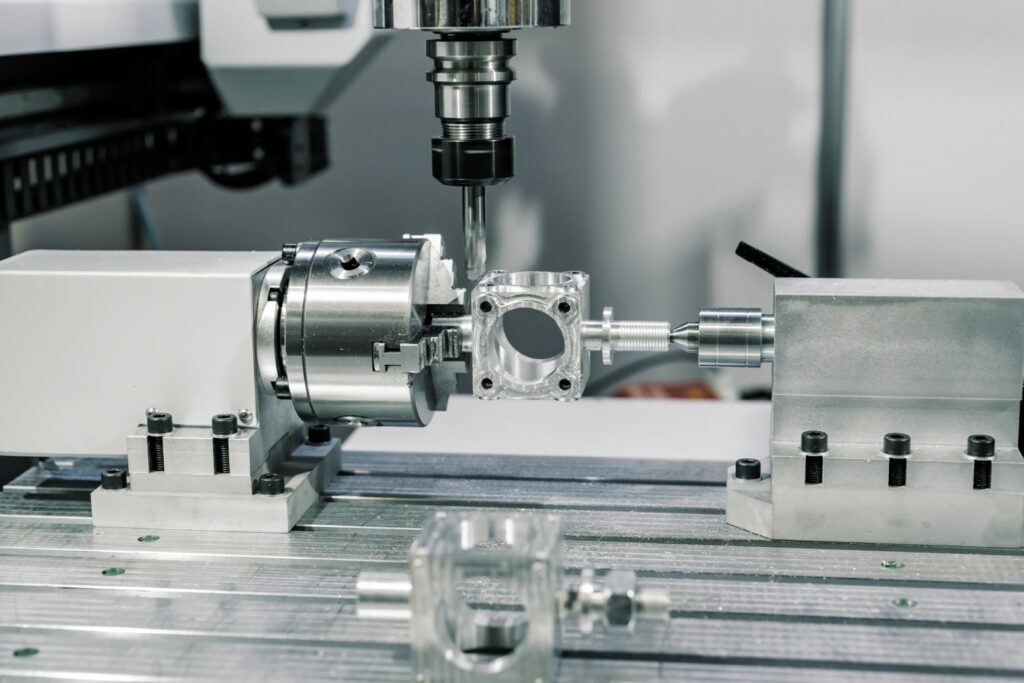

At Yijin Hardware, we specialize in Swiss machining services that combine precision turning and CNC machining. Our advanced CNC Swiss machines are designed to meet the rigorous demands of various industries, including aerospace and medical device manufacturing. Our team of machining experts ensures that each project adheres to strict quality standards and delivers precision machined parts that meet your specific needs.

What Materials Can Be Swiss Machined?

Swiss machining can handle stainless steel, brass, aluminum, plastic, titanium, carbon steel, copper, tool steel, Inconel, and nickel alloys, which makes it a flexible choice for different applications. Here are some commonly used materials:

Stainless Steel

Stainless steel is favored for its corrosion resistance and strength, making it ideal for medical devices and aerospace components.

Brass

Brass offers excellent machinability and conductivity, and it’s often used in electrical connectors and fittings.

Aluminum

Lightweight yet strong, aluminum is commonly machined for automotive and aerospace applications due to its favorable strength-to-weight ratio.

Plastics

Various plastics can be machined using Swiss techniques, suitable for industries requiring lightweight and non-corrosive components.

Titanium

Titanium’s high strength and low density make it perfect for aerospace applications where weight savings are critical.

Carbon Steel

Carbon steel is utilized for its toughness and wear resistance, often found in industrial machinery parts.

Copper

Copper provides excellent thermal and electrical conductivity, frequently used in electronic components.

Tool Steel

Tool steel is known for its hardness and durability, making it ideal for cutting tools and dies.

Inconel

Inconel is a nickel-chromium alloy known for its high-temperature strength, often used in aerospace and chemical processing industries.

Nickel Alloys

These alloys are resistant to corrosion and oxidation, and suitable for extreme environments in aerospace applications.

The Benefits of Swiss Machining

Swiss machining offers many advantages that make it a preferred choice for precision manufacturing:

- Tight Tolerances: Capable of achieving tolerances as tight as 0.0001 inches

- High Productivity: Efficient setup allows for high-volume production runs with minimal downtime

- Complex Geometries: Can create intricate designs in a single operation, reduces the need for secondary processes

- Cost-Effective: Streamlined operations lead to lower production costs over time

- Versatility: Suitable for a wide range of materials and applications across various industries

The Disadvantages of Swiss Machining

- Initial Setup Costs: The investment in specialized equipment can be high.

- Material Limitations: Not all materials are suitable for Swiss machining; some may require alternative methods.

- Skill Requirements: Operating Swiss-type lathes requires skilled technicians familiar with advanced machining processes.

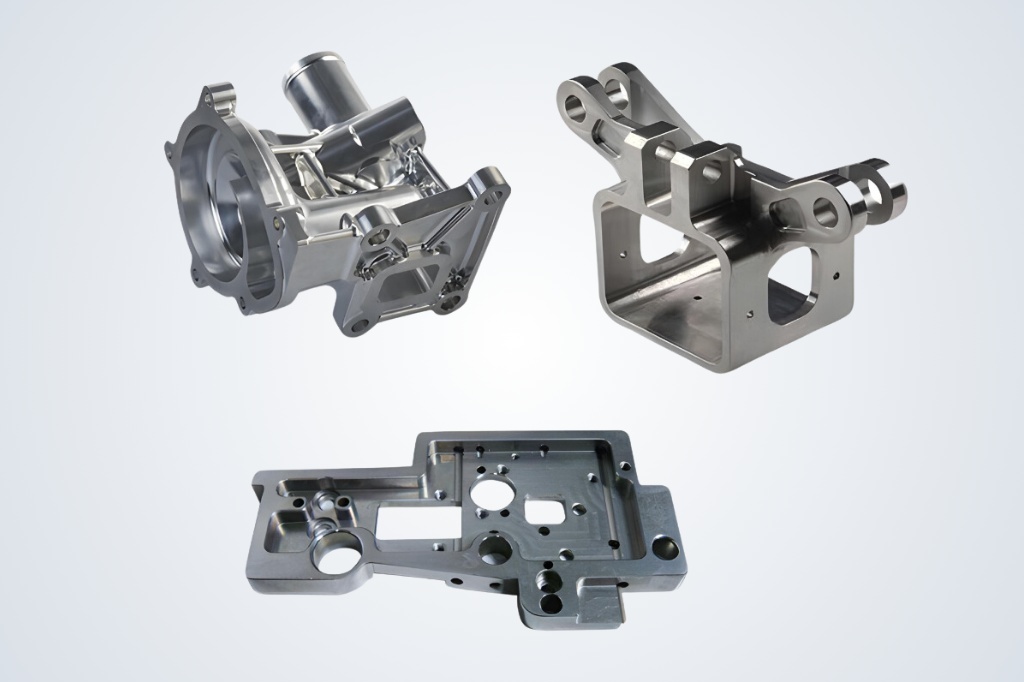

Swiss Machining Applications

- Aerospace: Production of complex components with stringent quality requirements

- Medical Device Manufacturing: Creation of precision machined parts essential for medical instruments

- Automotive: Manufacturing of high-performance components such as fuel injectors and valve bodies

- Electronics: Fabrication of small parts like connectors and housings

- Industrial Machinery: Production of durable components that withstand harsh conditions

Alternatives to Swiss Machining

Alternatives to Swiss machining include:

- Traditional CNC Machining: Suitable for larger parts, but may require multiple setups

- Turning Services: Standard lathes can be used for simpler geometries without advanced equipment

- 3D Printing: Offers rapid prototyping capabilities, however, Swiss machining has superior precision.

Why Choose Yijin Hardware for Swiss Machining Services?

Yijin Hardware is a leading provider of Swiss machining services due to our commitment to quality and precision. Our state-of-the-art CNC machines ensure that we meet the tight tolerances required by our clients across various industries.

In addition to our Swiss turning services, we offer comprehensive CNC machining services tailored to your specific needs. With our experienced team and advanced technology, we can produce precision machined parts efficiently and cost-effectively.

FAQs on Swiss Machining Service | Precision Turning, CNC Machining Solutions

Swiss screw machines, such as a Swiss turning machine or Swiss CNC lathe, operate by holding a workpiece in a guide bushing for stability while machining tools cut close to the support point. These machines excel at producing complex parts with tight tolerances by using multi-axis configurations and synchronized motions. Known for precision Swiss machining needs, they are ideal for industries requiring Swiss-machined parts with high accuracy and efficiency.

A Swiss CNC machine is a specialized Swiss lathe designed for high-precision operations, combining Swiss CNC turning and precision CNC milling to create intricate components. With advanced machining capabilities like turning solutions and multi-axis motion, it delivers superior performance for custom Swiss projects. These machines are often employed in a manufacturing company or machine shop to produce precision Swiss turning parts for industries like aerospace, medical, and automotive.

Yes, there are various types of Swiss-style machining, including CNC Swiss turning, precision CNC Swiss turning, and turning and CNC milling combinations. These processes are supported by Swiss CNC machining services that cater to complex parts, offering advanced options like CNC turning centers for high-volume production or Swiss CNC machining services for intricate designs. Different setups, such as automated Swiss machine lathes or ISO-certified processes, expand the versatility of CNC machining capabilities to meet diverse industry demands.

CNC Resources

What is Steel | Definition, Properties, and Composition Explained

Steel is an alloy that is primarily composed of iron and carbon, and it’s the world’s most widely used material.

Bronze vs. Copper: Key Differences, Uses, and Benefits

The main difference between bronze and copper is in their different composition — copper is a pure metal, whereas bronze

Bronze vs. Brass: Key Differences, Uses, and Which to Choose

The main difference between bronze and brass lies in their composition: bronze is an alloy primarily composed of copper and

Start today. Get parts made fast.

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

info@yijinsolution.com

info@yijinsolution.com (+86) 188-2253-7569

(+86) 188-2253-7569