Description

Products Material Introduction

The material used in the product is UNS S32760, which is a super duplex stainless steel, which needs to be used in the state of hot working and solution annealing.

As a super duplex stainless steel, it combines desirable aspects of austenitic and ferritic grades.

Higher chromium, molybdenum and nitrogen content results in a Pitting Resistance Equivalent Number (PREN) > 40, providing superior pitting and crevice corrosion performance over austenitic and duplex stainless steels, and a critical pitting temperature in excess of 50°C.

It offers a higher strength than austenitic and 22% Cr duplex stainless steels and is listed in NACE MR 0175 for acid environments and ASME for pressure vessel applications.

S32760 Chemical Composition:

| Cr | Ni | Mo | C | W | Cu |

| 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.030 Max | 0.5-1.0 | 0.50-1.0 |

| N | Mn | Si | P | S | Fe |

| 0.2-0.3 | 1.00 Max | 1.0 Max | 0.03 Max | 0.01 Max | Balance |

S32760 Mechanical Properties:

Tensile strength: 750-900 MPa

Yield Strength: 550 MPa

Elongation: ≥25%

Hardness: HB ≤ 310

Corrosion Resistance:

S32760 has excellent corrosion resistance and shows excellent corrosion resistance in various corrosive media.

It is particularly resistant to corrosion, pitting and stress corrosion cracking in acidic and chloride environments.

Welding Performance:

S32760 has good welding performance. During the welding process, arc welding, gas-shielded welding, or laser welding can be used for welding.

It should be noted that pre-heating and post-heating are required before welding to avoid problems such as intergranular corrosion and hydrogen cracking.

Grinding Performance:

Due to the high strength and hardness of S32760, it is necessary to use a suitable cutting process and tool material during grinding to ensure a better processing effect.

The performance of S32760 can be improved by properly adjusting the heat treatment process.

Appropriate aging treatment can enhance its corrosion resistance and mechanical properties.

Main features of S32760

- Excellent corrosion resistance in a wide range of aggressive chemicals.

- Pitting Resistance Equivalent Number(PREN) > 40.

- Excellent resistance to pitting and crevice corrosion in seawater and other chloride-containing environments.

- Critical pitting temperature exceeding 50°C(CPT).

- High strength compared to austenitic and 22%Cr duplex stainless steels.

- Excellent ductility and impact strength at both high and sub-zero temperatures

- High resistance to wear, erosion and cavitation

- Excellent resistance to stress corrosion cracking in chloride-containing environments

- Listed in NACE MR 0175 for acid service

- ASME Pressure Vessel Application Certification

Application

- Remove organic and fatty acids from the equipment.

- Applications for Propellers, shafts, rudders, shaft seals, pumps, bolts, fasteners, valves, and instruments for marine and shipbuilding.

- Gas industry pumps, valves, pipes, vessels, wellhead equipment, and subsea equipment.

- Pollution control systems, fans and pumps, wet scrubbers, incinerators, and flue gas desulfurization (FGD).

- Pulp and paper industry components such as black liquor heater tubes, digester vent valves, rotary feed valves, IDfans, brown stock scrubbers, settlers, and bleaching components.

- Food industry applications include sugar cane centrifuges, and corn and vegetable processing plants.

- Agrochemical production such as fertilizers (wet acid based).

- Sewage treatment, seawater cooling, seawater desalination plants.

Our Experience

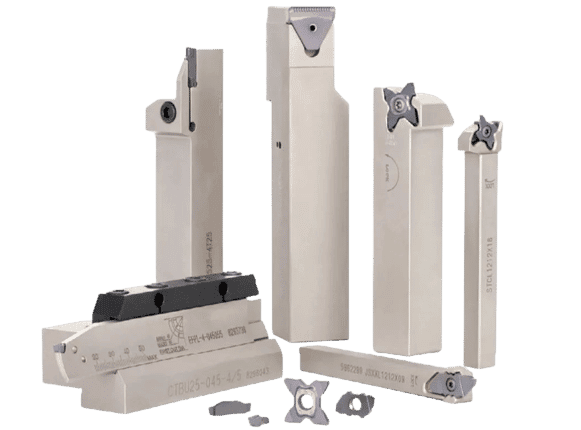

Yijin Solution is very experienced in processing S32760 materials.

The machine tools we used are imported from Switzerland, and the choice of tool blade is imported from Germany.

The testing equipment includes a two-dimensional projector and a Coordinate Measuring Machine to ensure that the product pass rate reaches 99.9%.

This set of parts is completed by CNC turning process, because this material is relatively hard, and it is very abrasive to the tool during processing.

Therefore, Yijin Solution adopts the idea of turning the raw materials into solid solutions before the product processing shortens the processing time and greatly reduces the cost of tool wear.

S32760 Duplex Stainless Steel Product Processing Difficulties

Because this product is used for the bearing seat bushing of petroleum equipment, it has requirements for the surface finish of the product and the tightness of the thread.

When the product is turned on the machine tool, it is necessary to adjust the machine tool to run at high speed.

However, in the process of high-speed operation, the wear of the tool will be relatively large, so the raw material is used for solid solution treatment.

When the S32760 duplex stainless steel material left the factory, it had not been solution treated, its hardness was unstable, and its degree was between 36 and 47 degrees.

The hardness of the SUS303 material is less than 23 degrees when it left the factory, and when the S32760 material is processed, the temperature generated during the tool turning process and the friction with the material is relatively high, the heat dissipation performance is poor, and a fire point will occur.

The SUS303 material has high toughness and high requirements on the tool, which is 5 times the normal tool wear, and requires high-cost tool processing.

For the S32760 material, if the normal outer diameter cutter processes 30 products, the cutter needs to be replaced.

When processing external threads, it is necessary to replace the outer round tooth cutter when processing 20 products.

When processing the deep hole of the inner hole, usually 16 products are processed, and the drill bit needs to be replaced.

The inner hole of S32760 material cannot be turned and milled directly, because the tool wear is very high, and the inner hole thread can only be processed by tapping for the time being.

For the processing of S32760 material, the taps need to be replaced when the taps are processed to about 10-15.

If it is not replaced, the screw teeth GO – NO GO FIXED GAUGES will be disqualification, and the frequency of tool replacement is too high, which will lead to a decrease in production and processing efficiency

Solve the S32760 material to make it have better corrosion resistance, plasticity, and formability.

S32760 material is especially suitable for:

- Parts that need to be reprocessed after heat treatment.

- Eliminates work hardening between forming processes.

- Welding workpiece. The raw materials are processed by CNC turning after solution treatment, and the cutting tools are all imported from Germany.

The above is a detailed introduction to the chemical composition and performance of S32760.

This stainless steel is widely used in marine engineering, petroleum, natural gas, chemical industry, etc., and shows excellent performance in extremely challenging environments.

This time, Yijin Solution has successfully processed parts made of S32760 materials for customers and delivered perfect products to our customers.

In summary, in the process of processing S32760 materials into finished parts, the selection of machine tools, tool selection, processing process selection, and technical personnel’s debugging of machine tools require a very experienced and capable CNC turning factory to complete.

Our factory can meet your various processing needs. Yijin Solution not only has a lot of experience in processing S32760 but also other materials. And provide customers with

- Drawing design suggestion

- Parts optimization suggestion

- Relevant certificates are available

(+86) 188-2253-7569

(+86) 188-2253-7569