Phenolic CNC Machining | Phenolic Material Processes, Machining Techniques

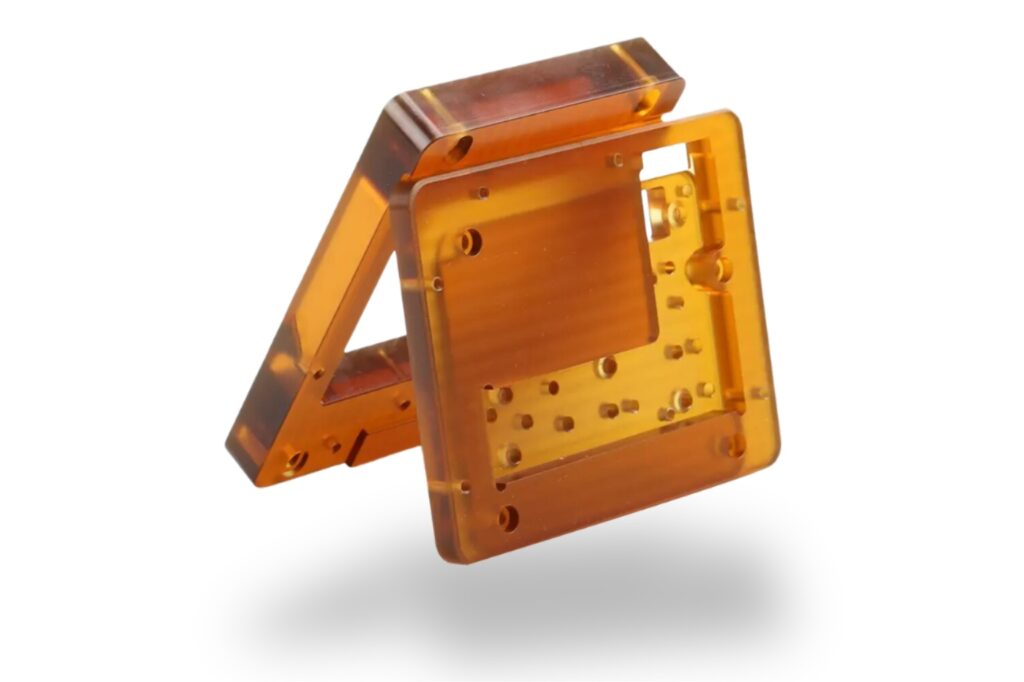

Phenolic CNC machining involves the precise shaping and cutting of phenolic materials using computer numerical control (CNC) technology. This process is essential for creating high-quality components used in various industries, including automotive and aerospace.

At Yijin Hardware, we provide stellar phenolic CNC machining services. As an ISO 9001 certified factory, we are committed to delivering exceptional results.

- ⬤Service

- ⬤Your Details

- ⬤Submit

What is Phenolic Resin?

Phenolic resin is a specific type of thermoset plastic created by polymerizing phenol with formaldehyde. Also called phenol formaldehyde (PF) resin, it’s known for its excellent thermal stability, mechanical strength, and resistance to chemicals and moisture.

These properties make phenolic resin a popular choice in manufacturing applications where durability and insulation are critical. Phenolic materials come in various forms, including laminates and composites, making them a versatile choice for different machining processes.

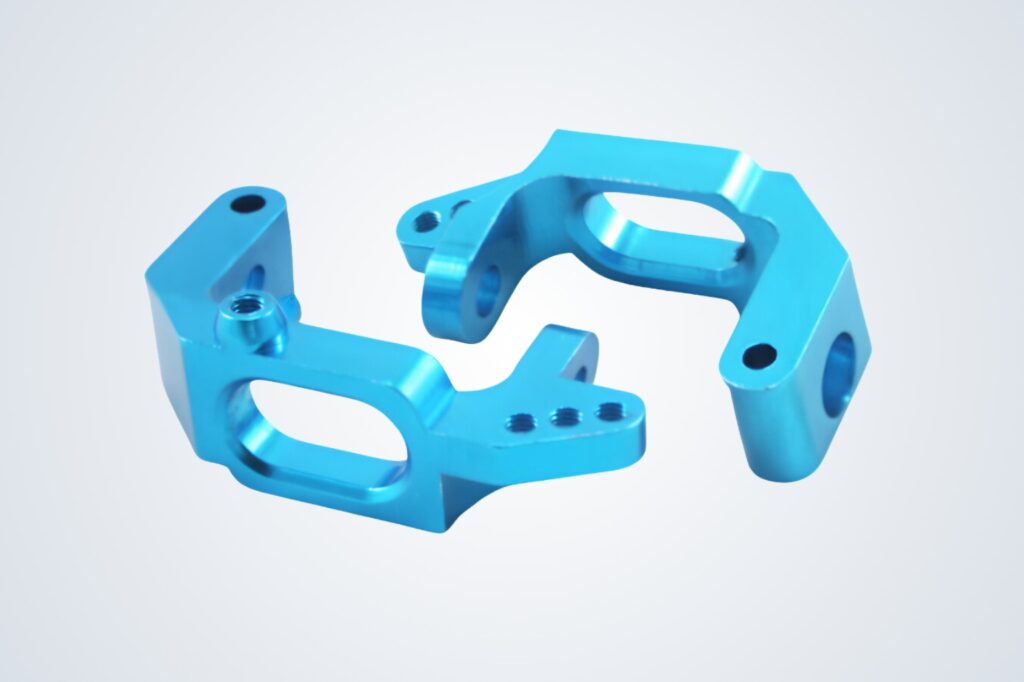

Our Phenolic CNC Machining Services

At Yijin Hardware, we offer comprehensive phenolic CNC machining services with free industrial designs tailored to meet the specific needs of our clients. Our premium equipment and skilled machinists ensure that each component is manufactured with precision and accuracy.

We handle various phenolic grades and types, allowing us to cater to diverse applications across multiple industries.

Types of Phenolic Grades

- Paper-Reinforced Phenolic is known for its good mechanical properties and dimensional stability. This grade is commonly used in electrical insulation applications.

- Canvas Phenolic and Linen Phenolic provide excellent strength and are suitable for applications requiring high durability.

- N-1 (Nylon Reinforced Phenolic) offers enhanced toughness and is ideal for applications where impact resistance is necessary.

- G-3 (Glass Reinforced Phenolic) is known for its superior mechanical properties. G-3 is often used in environments requiring heat resistance and impact strength.

- Non-Phenolic Fiber-Reinforced Composites:

- G7 (Glass Reinforced Silicone) offers excellent thermal stability and flexibility.

- G10 (Glass Reinforced Epoxy) is known for its electrical insulation properties; G10 is widely used in electronic applications.

- G11 (Glass Reinforced Epoxy) is similar to G10, but it has improved thermal resistance.

The Benefits of Phenolic CNC Machining with Yijin Hardware

Partnering with Yijin Hardware for your phenolic CNC machining needs comes with several advantages, including precision, versatility, and efficiency:

- Precision: Our advanced CNC machines ensure tight tolerances and high-quality finishes on all machined parts.

- Versatility: We work with a variety of phenolic grades, allowing us to meet diverse application requirements.

- Efficiency: Our streamlined processes enable us to handle both small and large production runs effectively.

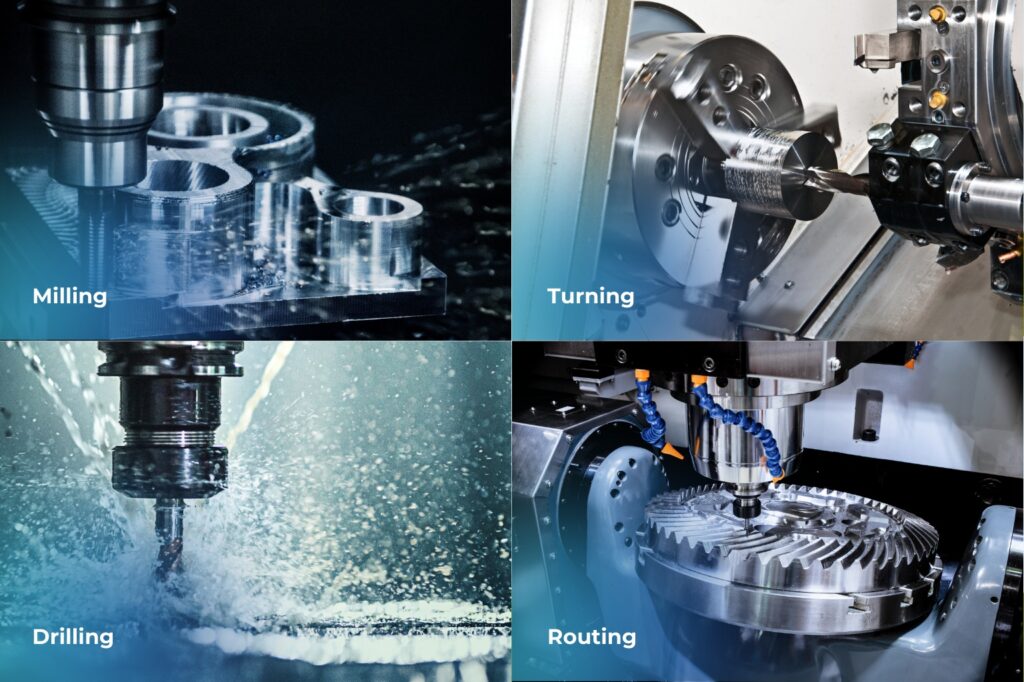

Types of Phenolic Material Machining Processes

| Process | Purpose | Method |

|---|---|---|

| Milling | Precise cuts | Carbide-equipped milling machines |

| Turning | Cylindrical shapes | Lathes for shaping phenolic stock |

| Drilling | Clean holes | High-speed drills to avoid material damage |

| Routing | Complex designs | Routing for intricate shapes and detailed components |

The types of machining processes we use for phenolic materials include milling, turning, drilling, and routing:

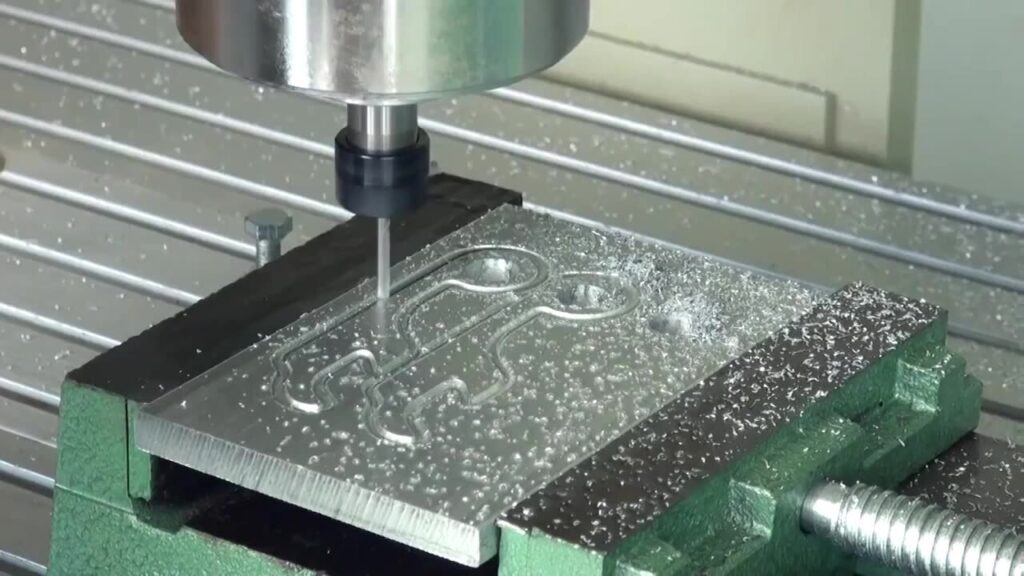

- Milling: Uses milling machines equipped with carbide tools to achieve precise cuts

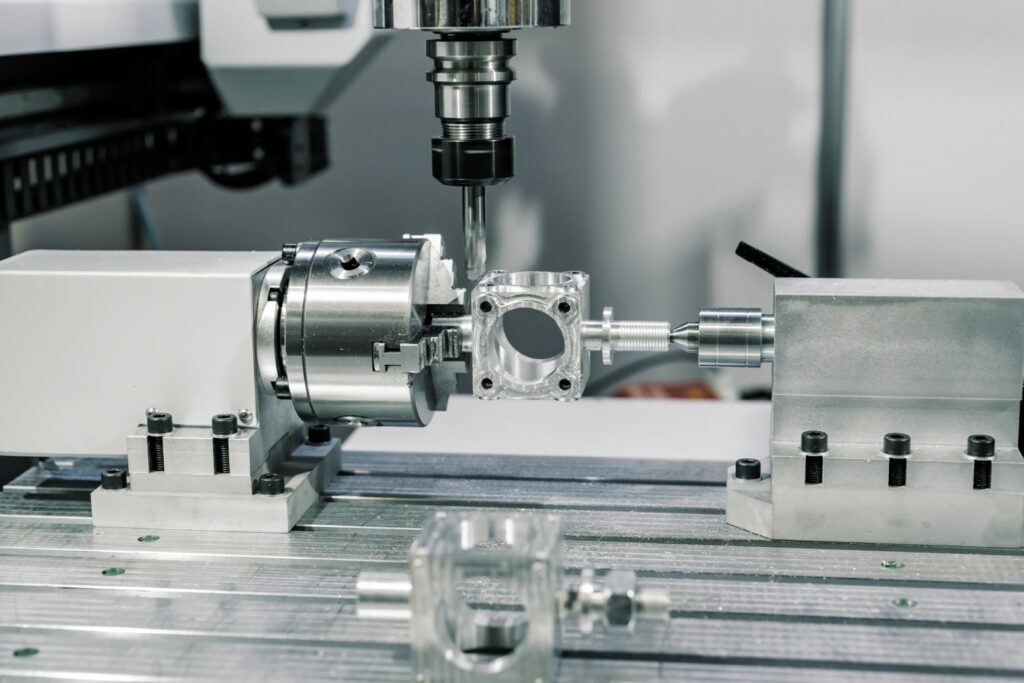

- Turning: Employs lathes to create cylindrical shapes from phenolic stock

- Drilling: Uses high-speed drills to create holes without damaging the material

- Routing: Ideal for complex shapes, routing allows for intricate designs in phenolic components

Each of these machining process types optimizes the characteristics of the specific phenolic material being used.

Applications of Phenolic Machined Parts

Phenolic machined parts are used in electrical insulation, automotive components, and aerospace applications:

- Electrical Insulation: Commonly used in printed circuit boards (PCBs) and electrical components due to their good electrical properties

- Automotive Components: Used in parts that require durability and heat resistance

- Aerospace Applications: Ideal for lightweight components that must withstand extreme conditions

These applications highlight the strength and versatility of phenolic materials, as well as their importance in modern manufacturing.

Alternatives to Phenolic Machining

Alternatives to phenolic machining include urethane casting, custom plastic injection molding, and plastic 3D printing. While phenolics are popular, these alternatives are worth considering based on specific project requirements and desired results:

- Urethane Casting is suitable for producing flexible parts with good abrasion resistance.

- Custom Plastic Injection Molding is effective for high-volume production of plastic components with complex geometries.

- Plastic 3D Printing offers rapid prototyping capabilities for custom designs without the need for traditional tooling.

Why Choose Yijin Hardware for Phenolic CNC Machining?

At Yijin Hardware, we pride ourselves on our commitment to quality and customer satisfaction. Our experienced team understands the complexities involved in machining phenolics and employs best practices throughout the manufacturing process.

We offer a range of CNC machining services tailored to your specific needs, ensuring you receive the best possible solution for your project. With our expertise in CNC machining services, you can trust us to deliver exceptional results every time.

Phenolic CNC Machining | Phenolic Material Processes, Machining Techniques FAQs

Phenolic machining typically requires precise CNC machining material selection guides to choose the right tools and techniques. During the machining processes in manufacturing, carbide or diamond-tipped tools are commonly used to minimize burr formation and handle the abrasive nature of phenolic resin binders. A cutting-edge spindle setup and proper coolant application are essential, particularly for paper phenolic machining services, to reduce heat and ensure a smooth finish.

Garolite is a specific subset of phenolic laminates, and although garolite typically contains fiberglass reinforcement for added strength, phenolic can vary. Phenolic can incorporate reinforcements like paper or linen to create CE phenolics or LE phenolics, respectively. Both materials use a phenolic resin binder, but garolite’s structure offers improved durability, making it suitable for spindle and abrasive applications made during manufacturing machining processes.

Phenolic machining hazards include wearing down tools and generating harmful dust during the machining process in manufacturing. Improper handling of NEMA-grade phenolics or plastic materials like CE phenolics can lead to burr issues or tool degradation, especially if coolant is not adequately used. Cutting-edge companies like Yijin Hardware recommend proper ventilation, dust collection systems, and even cryogenic techniques for safer and more effective machining types involving phenolic.

CNC Resources

What is Steel | Definition, Properties, and Composition Explained

Steel is an alloy that is primarily composed of iron and carbon, and it’s the world’s most widely used material.

Bronze vs. Copper: Key Differences, Uses, and Benefits

The main difference between bronze and copper is in their different composition — copper is a pure metal, whereas bronze

Bronze vs. Brass: Key Differences, Uses, and Which to Choose

The main difference between bronze and brass lies in their composition: bronze is an alloy primarily composed of copper and

Start today. Get parts made fast.

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

WhatsApp us

Please attach your 2D CAD drawings and 3D CAD models in any format including STEP, IGES, DWG, PDF, STL, etc. If you have multiple files, compress them into a ZIP or RAR. Alternatively, send your RFQ by email to info@yijinsolution.com.

Compressed Formats: .zip, .rar, .7z

Image Formats: .pdf, .jpg/.jpeg, .gif, .png, .webp, .tif/.tiff

Video Format: .mp4

Office Formats: .txt, .docx, .xlsx, .ppt, .ods

info@yijinsolution.com

info@yijinsolution.com (+86) 188-2253-7569

(+86) 188-2253-7569