The CNC machining center is a high-precision CNC machine tool. The CNC system is the core control center of the entire machining center, which is equivalent to the human brain and its importance is self-evident.

The numerical control system issues orders through a series of electronic components and circuits all over the machine tool and then completes the various processing procedures of the machine tool.

The numerical control technology in my country has developed rapidly in the past ten years, and the domestic CNC system for machining centers has occupied a certain market share.

As far as the current domestic machining center market is concerned, the CNC systems used in high-end mid-range models still need to be imported. The CNC system is highly technical, and there are many technical barriers.

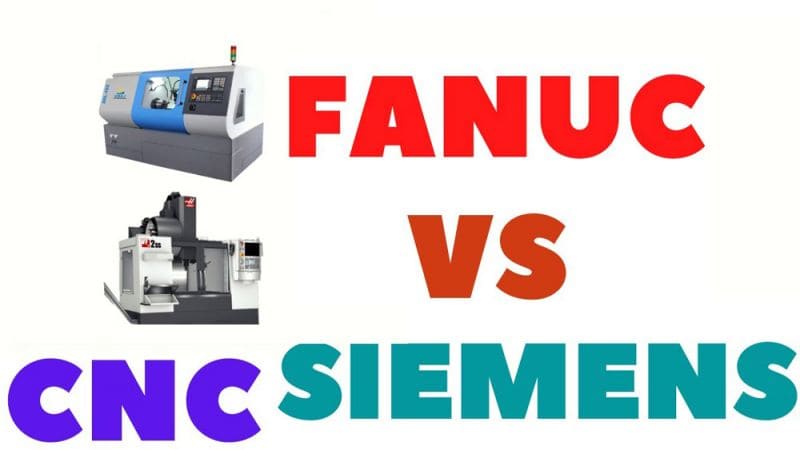

There are few good CNC system suppliers in the world, and Siemens and FANUC are undoubtedly the two giants of CNC systems for machining centers with the largest market share.

The operating principles of the Siemens CNC system and FANUC system are almost too many, and the operation interface, function matching, and programming methods are slightly different. Next, YIJIN Hardware will give you a detailed introduction to these two imported CNC systems.

FANUC CNC Machining Center

FANUC is a professional CNC manufacturer in Japan and the world’s largest professional manufacturer of CNC devices.

The earliest application of CNC systems to machine tool equipment has made outstanding contributions to the development of world industrial automation.

Siemens is a global enterprise in the field of electrical and electronic engineering. Siemens CNC is a department of the company.

Siemens and FANUC also design other product areas, such as FANUC robots and Siemens appliances. It has nothing to do with our CNC machining center industry, so we won’t repeat it here.

Siemens CNC System

FANUC systems generally use isolated power supplies, from three-phase 380V to 200V. The SIEMENS numerical control system is 380V commercial power. In contrast, the FANUC system is more suitable for the current grid requirements of our country.

A major requirement of the Siemens CNC system is the high power grid requirements, which are not suitable for the current domestic power grid conditions.

Development Level

Siemens’s numerical control has a relatively high level of development and has achieved channel control. But it is not very stable.

Friends who configure imported Siemens CNC systems must know that PLC crashes or program losses in Siemens CNC systems are common faults in maintenance.

However, FANUC’s PLC program has better stability and generally does not crash.

Unless the system fails, there is generally no program loss. If you are interested in CNC machining programming technology, contact our experts freely.

Getting Started

The operating system should comprehensively consider the programming situation, ease of use, and ease of learning.

Take common metal-cutting operations as an example, there is not much difference in programming between the two. G code and M code are still the most important programming methods.

In terms of ease of use, the Siemens CNC system is even better. Even if the user has no knowledge of workpiece technology and programming foundation, he can still use the shop mill and graphic programming functions to complete the programming process.

In terms of ease of learning, the FANUC panel has many functions and is difficult to master. Must remember the key name and function. Siemens is relatively easy, only three keys can be operated, and the screen prompts can complete the rest.

In this actual use situation, the current domestic machining center imported CNC system market uses slightly more FANUC systems than Siemens.

These two CNC systems can represent the highest level of currently imported CNC systems.

info@yijinsolution.com

info@yijinsolution.com (+86) 188-2253-7569

(+86) 188-2253-7569