Machining UHMW Polyethylene | UHMW-PE CNC Machining Service

UHMW-PE, or ultra-high molecular weight polyethylene, is a type of plastic known for its great durability and low friction properties. It is widely used in various industrial applications due to its high impact strength and abrasion resistance. At Yijin Hardware, we are experienced in providing expert CNC machining services that produce custom UHMW parts tailored to meet your needs.

- ⬤Service

- ⬤Your Details

- ⬤Submit

What is UHMW-PE for CNC Machining?

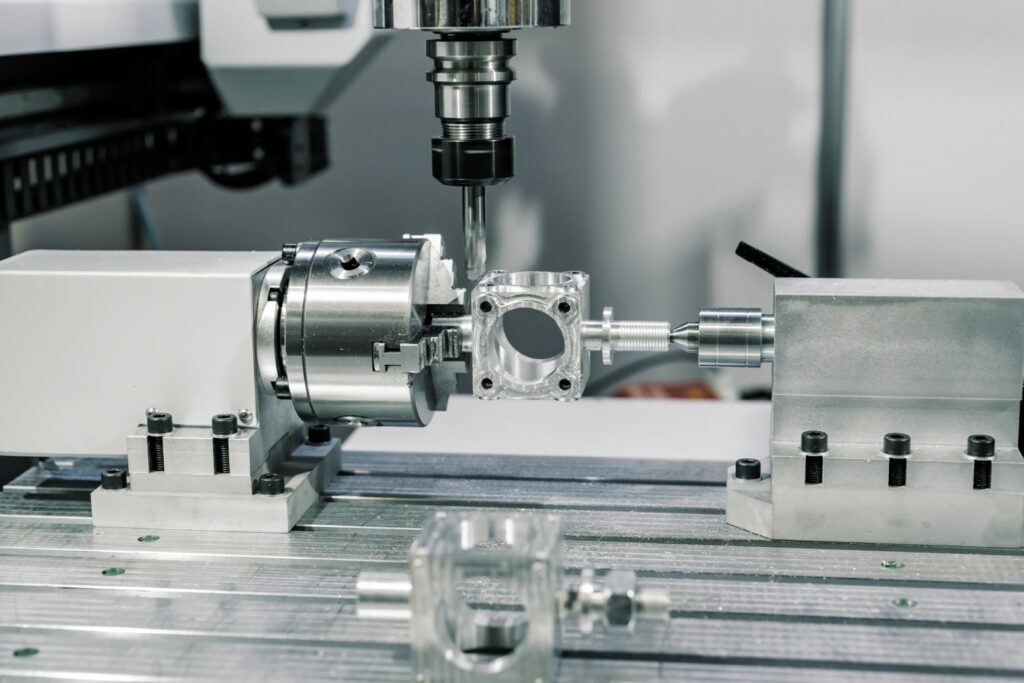

UHMW-PE is a thermoplastic made from extremely long chains of polyethylene, which gives it a very high molecular weight. This structure results in superior mechanical properties compared to standard polyethylene. It is commonly used in manufacturing parts that require high performance, such as bearings, wear strips, and guides.

Yijin Hardware’s UHMW-PE for CNC Machining Services

Yijin Hardware is highly proficient in precision CNC machining services for UHMW-PE, offering unmatched quality and customization. Our advanced machining capabilities produce durable, low-friction UHMW machined parts tailored for industries such as food processing, automotive, and industrial equipment. From custom parts to high-volume production runs, our team ensures every component meets strict performance and durability standards.

Generic UHMW-PE

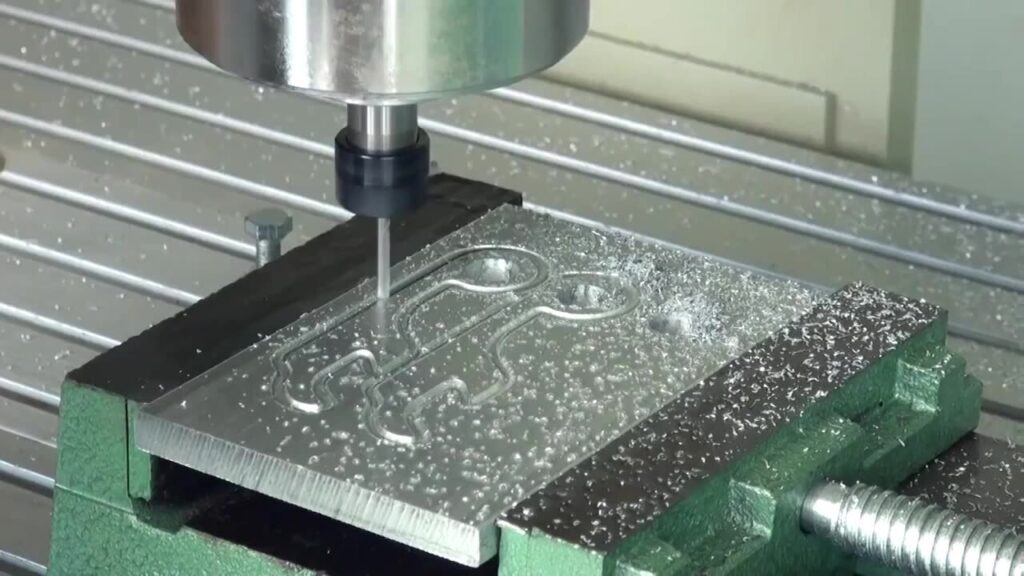

Generic UHMW-PE is the standard form of this material, often used in medical and defense applications where durability and low friction are essential. It can be processed using different machining techniques, including CNC milling and turning, to create precise components for diverse industries.

Generic UHMW-PE Properties

| Property | Unit |

|---|---|

| Molecular Weight | > 3 million g/mol |

| Coefficient of Friction | Low (0.1 – 0.2) |

| Impact Strength | High (up to 10 times greater than HDPE) |

| Abrasion Resistance | Excellent |

| Chemical Resistance | Good (resistant to solvents and corrosive materials) |

| Temperature Range | -200 to 200 °F |

| Coefficient of Thermal Expansion | Low (approx. 0.00001 in/in/°F) |

Finishes

When machining UHMW-PE, various surface finishes can be achieved depending on the application requirements, including standard, polished, and textured finishes. Common finishes include:

- Standard Finish: Suitable for most applications

- Polished Finish: Enhances aesthetic appeal and reduces friction

- Textured Finish: Improves grip and reduces slippage in applications like conveyor systems

Machining UHMW Polyethylene: How to Save Money

To save money when machining UHMW polyethylene, consider the following money-saving strategies, including optimizing the design, batch production, choosing the right machining techniques, and using quality cutting tools:

- Optimize Design: Simplify designs to reduce machining time and material waste

- Batch Production: Produce parts in larger quantities to lower per-unit costs

- Select Appropriate Machining Techniques: Use CNC milling or turning efficiently to minimize material loss

- Use Quality Cutting Tools: Invest in durable cutting tools to reduce wear and prolong their lifespan

By implementing these practices, companies can effectively manage costs while maintaining high-quality production standards.

Why Choose Yijin Hardware for Machining UHMW Polyethylene?

Yijin Hardware is a leading provider of machining services for UHMW polyethylene due to our commitment to quality and precision. Our premium CNC machining capabilities allow us to produce custom UHMW parts with tight tolerances, ensuring that each component meets exact specifications.

We offer a range of services, including CNC milling, turning, and laser cutting, tailored to meet the diverse needs of our clients across various industries. Whether you need prototypes or large production runs, our experienced team is ready to deliver high-quality machined parts that excel in performance.

FAQs on Machining UHMW Polyethylene | UHMW-PE CNC Machining Service

Yes, UHMW plastic is highly machinable due to its toughness and durability, making it a preferred material for UHMW machining processes. Ultra-high molecular weight polyethylene (UHMW-PE) is often used to produce custom parts for applications such as food processing and industrial machinery. Its low coefficient of friction and wear resistance make it ideal for precision CNC machining to create UHMW-machined parts with excellent reliability.

The cutting speed of UHMW polyethylene machining varies, typically ranging from 600 to 1,000 feet per minute, depending on the tooling and fabrication method used. This material requires sharp tools and proper feeds to prevent melting during plastic machining or UHMW machining. Unlike nylon, UHMWPE’s thermal resistance allows for effective cutting when creating custom parts and components for industrial applications.

Yes, precision CNC machining is an ideal method for machining polyethylene (PE), including ultra-high molecular weight polyethylene (UHMWPE). While CNC is preferred for UHMW, processes like UHMW laser cutting are less common due to the material’s thermal properties.

CNC Resources

What is Steel | Definition, Properties, and Composition Explained

Steel is an alloy that is primarily composed of iron and carbon, and it’s the world’s most widely used material.

Bronze vs. Copper: Key Differences, Uses, and Benefits

The main difference between bronze and copper is in their different composition — copper is a pure metal, whereas bronze

Bronze vs. Brass: Key Differences, Uses, and Which to Choose

The main difference between bronze and brass lies in their composition: bronze is an alloy primarily composed of copper and

Start today. Get parts made fast.

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

info@yijinsolution.com

info@yijinsolution.com (+86) 188-2253-7569

(+86) 188-2253-7569