Hey, do you know that the CNC machine was invented in the 17th century? But this is not the end of the story. What is more interesting to know is that it was not much in use until the 1940s. However, today, it is a widely used tool for product creation in a variety of industries. With a CNC machine, you can easily make precise cutting. Plus, you can create multiple identical products at once.

Sounds great?

But wait. Before getting started using CNC to create your products, first you need to answer a few questions. Like How much does it cost, and what factors can affect this cost?

And if that is the case, then you’ve landed in the right place!

Continue read on to learn everything you need to know about custom CNC milling costs.

For further reading, you may also like: CNC Machining Cost: Factors & Tips

What is CNC Milling?

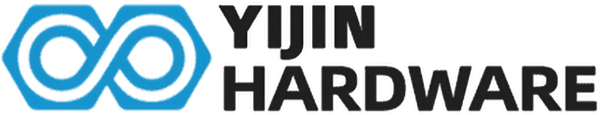

The full form of CNC is a Computer-numerical machine. As its name shows, a computer controls the milling machine. Now, if you are searching for a clear understanding of what a CNC milling machine is and how it works? Then, you must have the fundamentals of milling.

Milling is a machining process that includes the use of rotating cutters to remove portions of a block of material. And this process is kept in the running until the desired or final custom shape is ready.

Here is the one thing to notice the process begins with a CAD model. After that this model is converted into a CNC program and then goes to set up in the CNC machine.

You know, CNC milling machines are super versatile. You can use them for all sorts of applications across different industries. They’re amazing at creating complex 3D shapes. You’ll find them being used in places like the automotive industry, aerospace, and even in the medical field.

What’s really cool is that these machines can handle a wide range of materials. They can work with metals like aluminum and steel, and they’re also great with plastics and composites. It’s pretty impressive!

Read More:

Benefits of CNC Machining and Milling

How Does CNC Milling Work?

If we talk in simple language, then CNC milling machines read the instructions and then apply them to operation. And you know what the reason behind this process is the 3D CAD file. Yes, which represents the final part.

So when this process is complete then design is ready to be converted into a machine-readable format. And, next, CAM software (Full form is computer-aided manufacturing) exports this to the CNC machine program. Note that this program exports usually in G-code format.

This G-code format plays the role of instructions and directs the every move that the machines makes. It copies CAD designs using preferred materials with high accuracy and efficiency.

Read More:

Types of CNC Milling Operations

How Much Does CNC Milling Cost (Or How to Calculate CNC Milling Cost?)

The cost of a CNC milling machine simply depends on its uses.

So, before placing an order, it is important to look at your project’s overall budget. As mentioned above, there are a number of factors that affect its cost, which we will discuss below in detail.

Just to give you an idea: According to Custom Componets Report, 3-axis machines are pretty common and tend to run at around $35-$40 per hour. Different machines, such as multi-axis machines, require more advanced operation. Because of this, it runs in a higher price range of around $75-$120 per hour.

For example, in the UK, CNC milling is normally costed by the hour. So, calculatively, the rate for CNC milling depends on the time spent on manufacturing multiplied by the hourly rate.

When calculating the price for CNC milling, manufacturing processes include programming, setting up machine tools, de-burring, and inspection.

As there is a famous saying, “You get what you pay for.”

Now, calculating custom CNC milling costs involves various factors related to material, machine, labor, tooling, and overhead expenses.

Below, I am mentioning the step-by-step guide on how to calculate CNC milling cost estimate:

Material Cost

To determine the material cost, you must know the material cost per unit and the material volume.

Material Cost = Material price/unit X Material volume

Labor Cost

To calculate the labor cost, you must know three things: the machine operator’s hourly rate, the total machining time required for the job, and the machine’s setup time costs.

Labor Cost = (Machine Operator hourly rate x Machining time in hours) + setup time cost

Machine Cost

To get the machine cost, determine the hourly rate for using the milling machine and calculate the total machining time for a specific job.

Machine cost = Machine Hourly rate x Machining time in hours

Tooling Cost

To determine the tooling cost, you must know three things: the cost of tooling setup, the cost of tool replacement, and the number of tool changes.

Tooling Cost = Tooling setup cost + (Tool replacement cost per tool x number of tool changes)

Overhead Cost

Lastly, to get overhead cost, find out the overhead rate, which is usually a percentage of the machine cost and total machine time in hours.

Overhead Cost = Overhead Rate x Machining time in hours

Now, after getting all these individual costs, we will sum up all of them to get the final CNC milling costs estimate.

So our total cost would be:

Total Cost = Material Cost + Labor Cost + Machine Cost + Tooling Cost + Overhead Cost

It’s essential to work closely with the machining facility to get accurate estimates for each parameter.

Factors Affect The Cost of CNC Milling

A number of diverse factors will contribute to the overall cost of the CNC milling process. Below, I am mentioning the six things that can impact the bottom line:

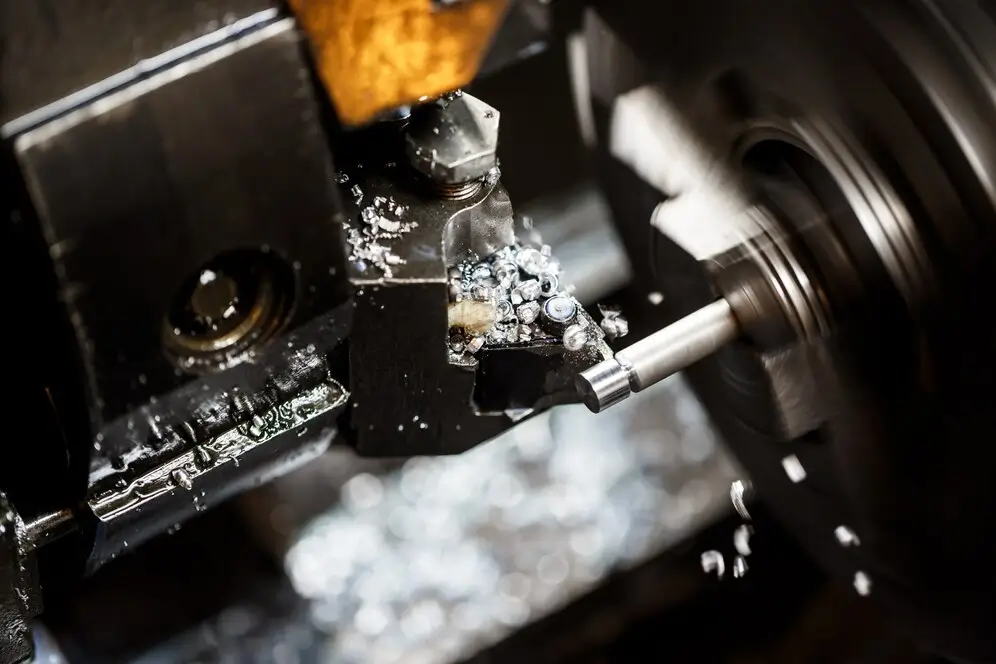

Tools

Necessary tools for CNC milling require fixtures, tool holders, jigs, and loading mechanisms, among others. Milling requires both cooling liquids and tools. Both elements will eventually need to be changed over time. Because cutting tools will not last as long as liquids since they are responsible for cutting dense materials.

Materials

Every milling process starts with a manufacturing project. Therefore, to begin with, money is spent on the necessary materials. Milling is all about geometry and shape. You will have to make the material in one of two forms: plates or sheets and cubes.

Machining

As expected, milling uses a lot of electricity. 5-axis CNC milling machines use a lot of electricity. Most devices are already installed with pneumatic systems to increase performance. And this additional system will only use more energy. Similarly, costs will only increase if finished parts have to be processed on multiple machines.

Quality

Each milled part has different quality requirements. A precise and polished finish will come with a higher cost. Milling manufacturing operations keep track of the number of defective products based on the rate given to the customer.

Technician

Milling jobs will require many technicians to achieve the best results possible. Utilizing a trained professional will always cost money. Similarly, costs will increase based on how much care the job/material needs.

Shipping

Yes, there are a lot of shipping options nowadays, but most milling companies have pre-existing partnerships to handle logistics. So, the worry of shipping will be taken out of the customer’s hands, but it can be costly.

Tips to Reduce the CNC Milling Cost

The cost is still important for either small or big businesses. Everyone wants to find the balance between cost, quality, timing, and service. So, how do you reduce the cost of your custom machining parts with CNC milling? Below are some useful tips in detail, which you may find out it’s much simpler than you think:

Choose of RAW Material

Raw materials play a huge role in production cost inflation. You can save a lot of money by being wise with material selection. We’re not asking you to compromise on the quality by any means; in fact, using cheap, substandard material often leads to unexpected expenses.

The price for your material is usually quoted for a sheet measuring 6”x6”x1”. Here are the prices for a few commonly used plastic sheets:

- Each block of ABS is priced at $17.

- The price for a block of POM (Delrin) is $27.

- The price for a block of Nylon 6 is $30.

Here are the prices of a few commonly used metals for CNC machined parts:

- The price for Aluminum 6061 is $25 per block.

- The price for Aluminum 7075 is $80 per block.

- And, the price for a block of Stainless steel 304 is $90.

The trick is to choose materials that are:

- Inexpensive enough to suit your budget.

- Easily available.

- Able to meet your design requirements with desired precision.

Avoid the Number of Setups

You’ve listed your raw materials and selected the process. You already know what the final product will look like. Now come the middle steps: operations and setups.

Each machined part involves one or many operations. Every operation necessitates a series of setups. There is a machine setup, of course. But there is also CAM programming, part fixturing, material setup, and more.

You can skip all the mess — and expenses — by cutting down on the number of setups. Most parts can be wrapped up in six setups or less. Try to get this number down to two necessary steps — or one, if possible.

Specify Tolerances

Specifications are crucial for precision CNC machining. Entrepreneurs usually define what they want and how they want it. But part design — specifically, tighter CNC machining tolerances — has a huge impact on production costs.

You may specify tolerances for certain critical features and functions if absolutely necessary.

Why Choose Yijin Hardware As Your CNC Milling Partner?

Yijin Hardware offers reliable CNC milling services for customers worldwide, providing rapid prototypes and production parts with tight tolerances, high accuracy, and various materials available. As a professional company that makes CNC milling parts, YIJIN Hardware has put in place a full quality control system that covers everything from contact to production and inspection to ensure the quality of your parts.

YiJin has been making CNC milling parts for more than 20 years and can give you the best CNC parts-cutting services in the business.

Would you like to know more about machining projects or need help with one? You can contact us anytime.

Conclusion

If you’ve come this far, you already know about CNC milling and its cost. Now, if you are looking for a trustworthy Precision CNC Machining manufacturer in China, look no further!

When selecting a CNC machining manufacturer, you should consider the machine’s quality and dependability. And that’s where Yijin comes into the frame. We specialize in precision CNC machining. Yijin is committed to top quality and precision. Don’t look any further, contact us today.

(+86) 188-2253-7569

(+86) 188-2253-7569